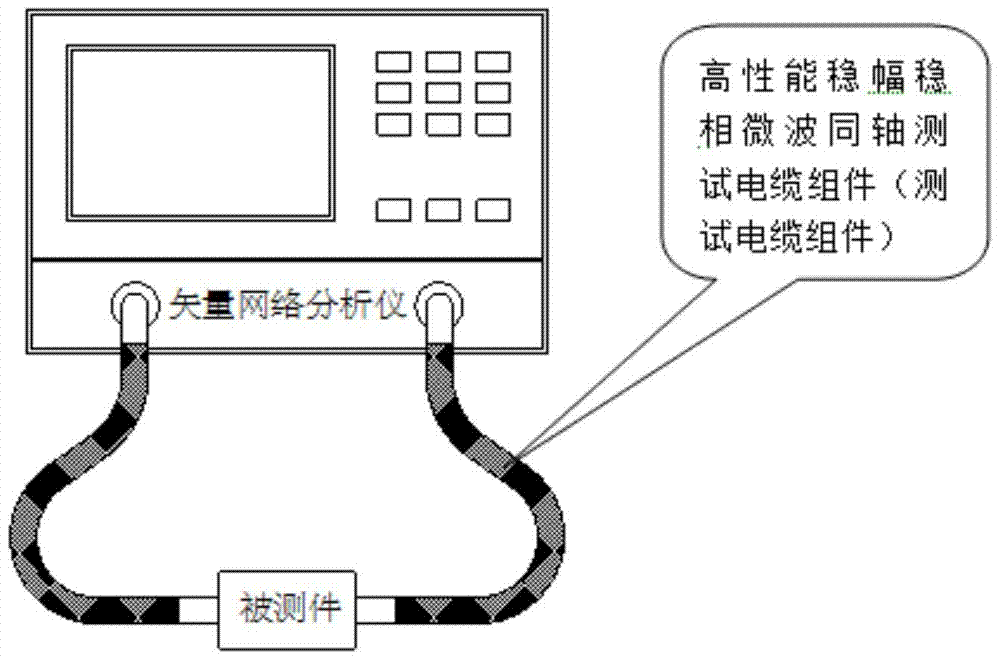

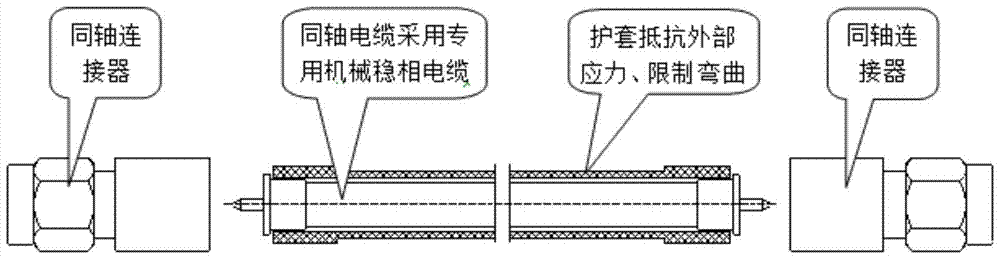

Method and assembly for improving mechanical phase stability of flexible microwave coaxial cable

A coaxial cable, microwave technology, applied in electrical components, parts of connecting devices, circuit/collector parts, etc., can solve the problems of low pass rate, non-uniformity, length processing error, etc., to improve the yield and Consistency, reducing the effect of transmission phase, reducing the effect of stress variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

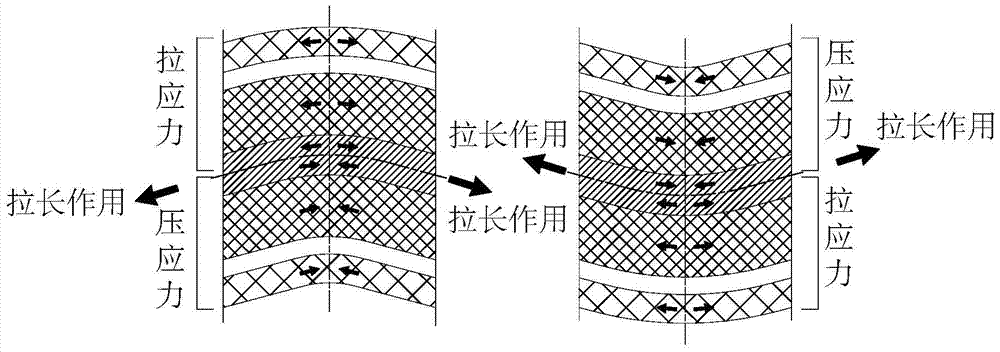

[0021] A method of improving the mechanical phase stability of a flexible microwave coaxial cable by applying pretension at both ends of the coaxial cable. The pre-tensioning force makes the coaxial cable in a tensioned state. At this time, the elongation of the coaxial cable becomes smaller under the same bending radius, and the pre-tensioning force causes the materials on both sides of the inner and outer sides of the bending radius to be subjected to tensile stress at the same time. The stress variation range of the material during reciprocating bending is reduced. This will signific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com