Smart electric switch sliding sleeve

An electric switch and sliding sleeve technology, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of increased cost and prolonged operation time, and achieves a construction cost saving, simple construction and strong integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

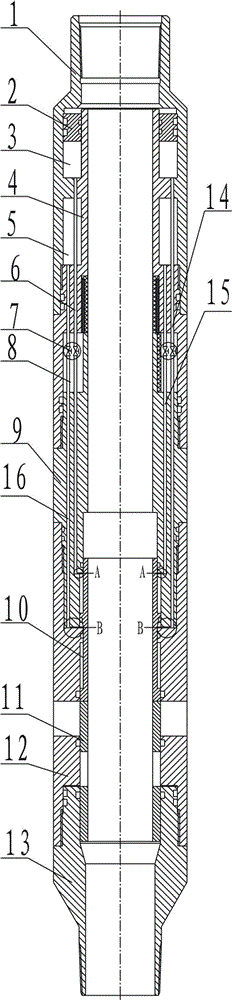

[0022] The present invention will be further described below in conjunction with accompanying drawing.

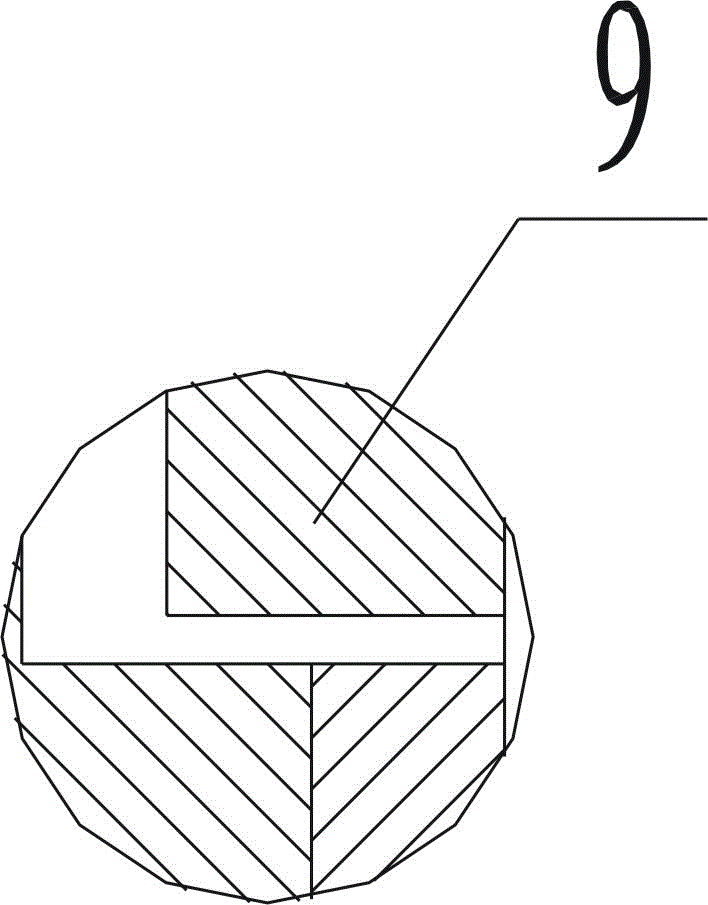

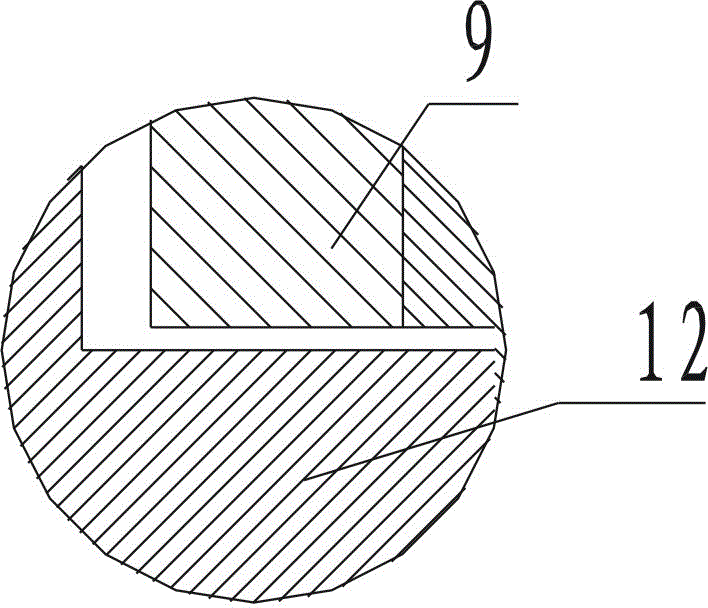

[0023] Such as figure 1 , 2 , 3, the intelligent electric switch sliding sleeve includes an upper variable button joint 1, a hydraulic piston 2, a first manifold joint 4, a second manifold joint 9, a power piston 10, a sliding sleeve outer cylinder 12, and a sliding sleeve core 11 , the lower variable button joint 13 and the circuit control module, the upper variable button joint 1 is set on the upper end of the first manifold joint 4, the hydraulic piston 2 is set on the upper end of the first manifold joint 4, and its lower end is connected with the upper variable button joint 1 The inner wall and the outer wall of the first manifold joint 4 form a hydraulic chamber 3, and a discharge cavity 5 is provided between the inner wall of the upper change button joint 1 and the outer wall of the first manifold joint 4, and the lower end of the first manifold joint 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com