Small gasoline engine integrated anti-dump fuel tank cap carbon canister

A small gasoline engine, anti-dumping technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of increasing exhaust emissions, enriching the intake gasoline concentration of the engine, and increasing the number of accessories, so as to ensure the working capacity and reduce the connection Pipeline, avoid the effect of excessive pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

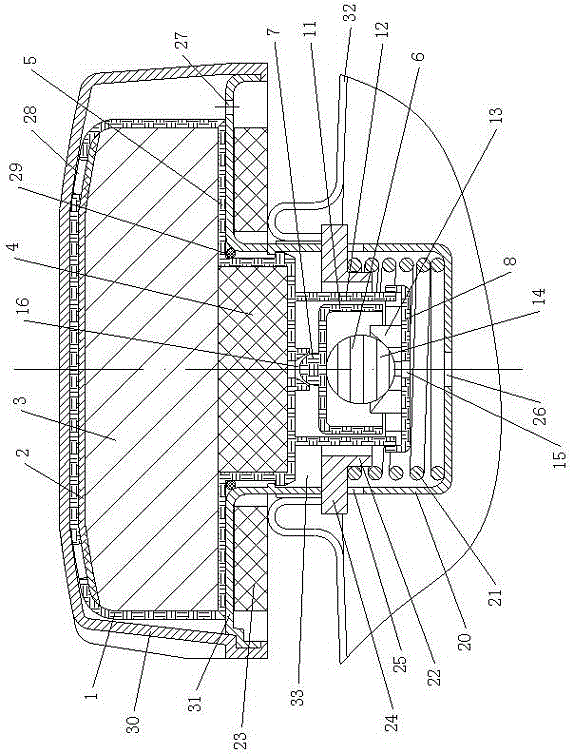

[0012] Below in conjunction with accompanying drawing, the specific embodiment of the present utility model is described further.

[0013] like figure 1 The shown small gasoline engine integrated anti-dump fuel cap canister of the present invention includes a fuel cap cover, a fuel evaporation control device, a fuel cap locking device, and a sealing O-ring.

[0014] The fuel evaporation control device includes the upper casing of the canister 1, the non-woven filter cloth 2, the activated carbon 3, the sponge 4, the lower casing of the canister 5, the steel ball (rolling ball) 6, and the valve body 11 with a hemispherical valve core 7 at the upper end And lower housing cover 8, guide sleeve 12, steel ball seat (rolling ball seat) 13.

[0015] The non-woven filter cloth 2 is paved on the bottom of the upper casing 1 of the carbon canister, and activated carbon 3 is loaded inside, and then the sponge 4 is installed in the groove 5 of the lower casing of the carbon canister, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com