Pump aggregate

An assembly and shell technology, applied in the direction of pumps, multi-cylinder pumps, pump components, etc., can solve the problems of high directional control valve, large pump assembly, large size, etc., to achieve increased weight saving, high uniformity, weight saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

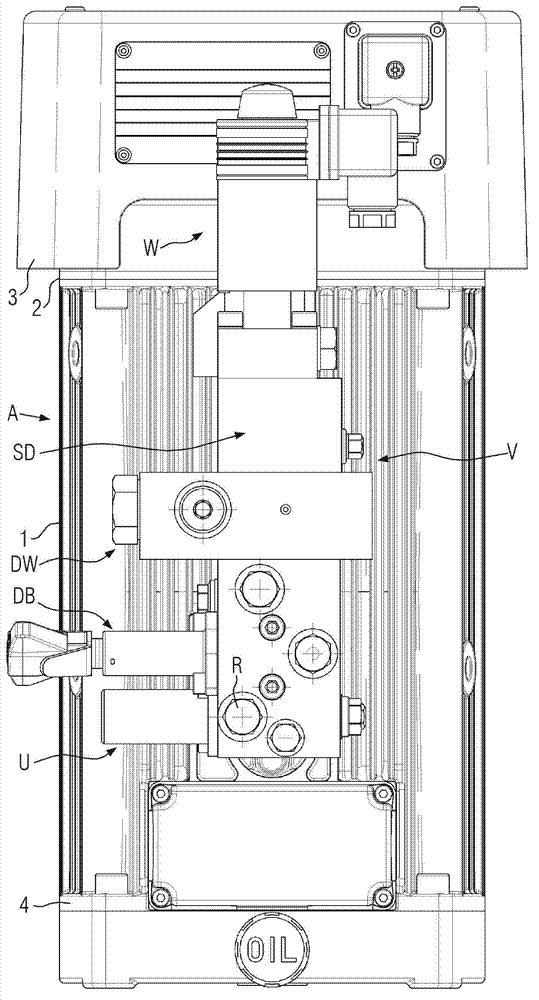

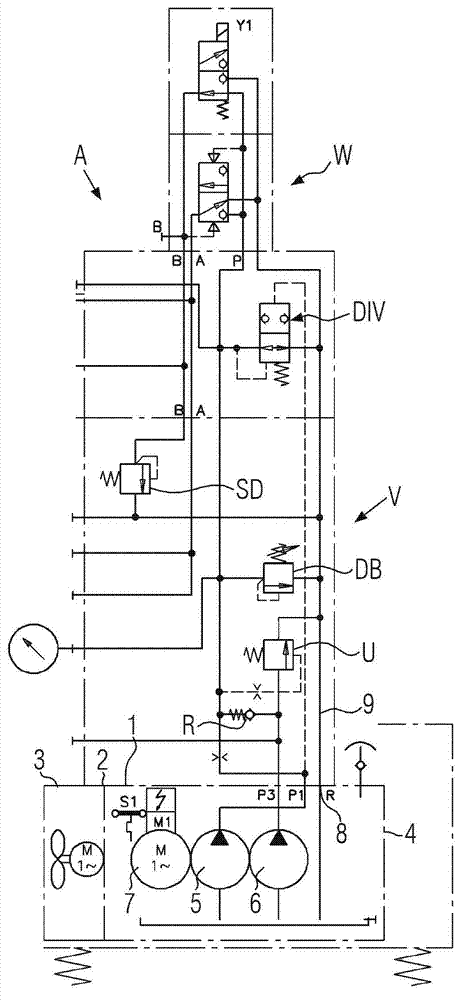

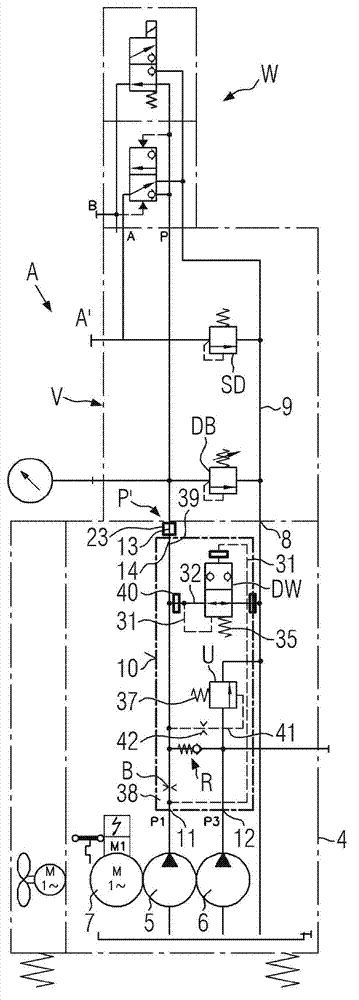

[0034] refer to explaining figure 1 and 2 prior art reference numerals used for equipment parts, in each embodiment of the pump assembly A showing the present invention Figures 3 to 15 Equipment parts with the same function and reference numerals also appear in .

[0035] Compared figure 1 and 3It has been shown that for a given performance specification the housing 1, 2, 3, 4 of the pump assembly A according to the invention has the same figure 1 The same external dimensions as the known pump assembly A. However, in figure 1 In the known pump assembly A in , the external valve combination V consists of a low pressure changeover valve U, a check valve R, a system pressure limiting valve DB, a pressure bypass switch DW with a dispensed orifice B and optionally an auxiliary pressure limiting valve SD ( image 3 ). Now, the pump unit A according to the invention comprises only the system pressure limiting valve DB, an optionally provided auxiliary pressure limiting valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com