Automatic locking mechanism for tooth-shaped revolving shaft

An automatic locking and tooth-shaped technology, applied in the field of machinery, to achieve good application value and promotion prospects, compact shape and reliable locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

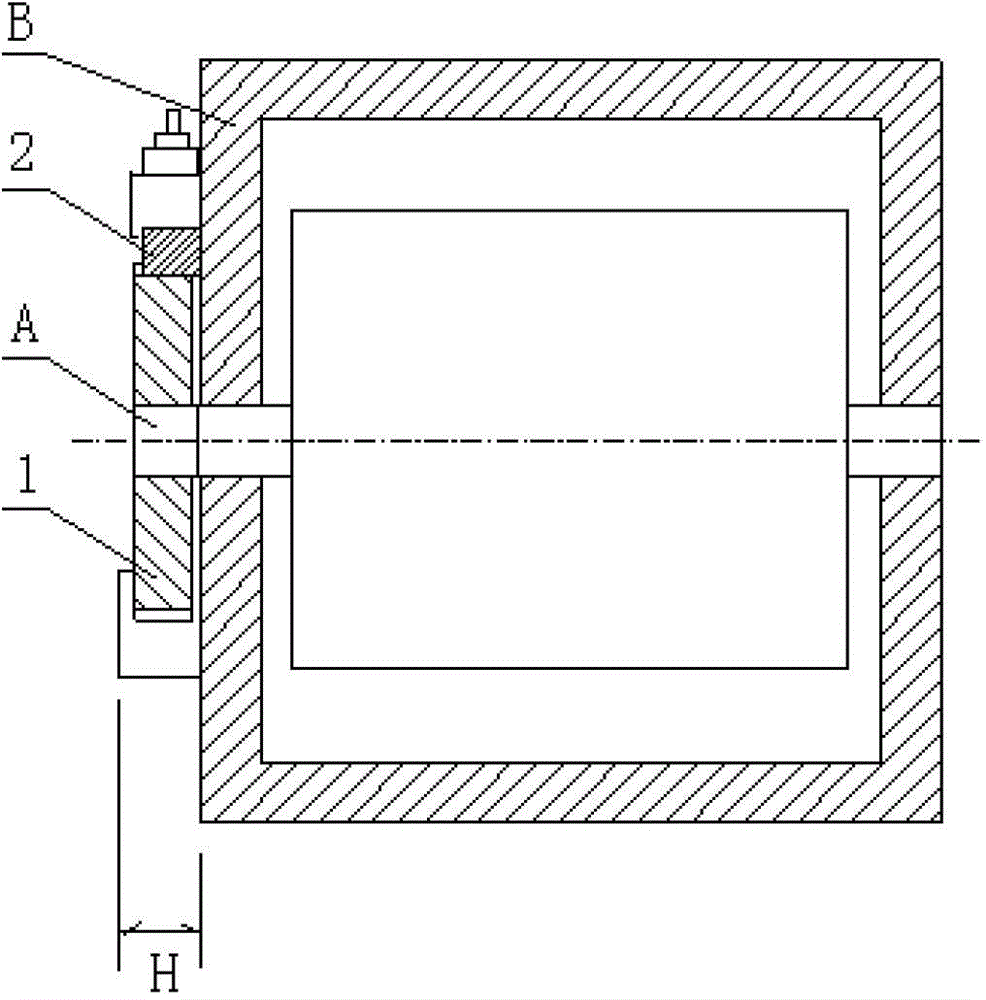

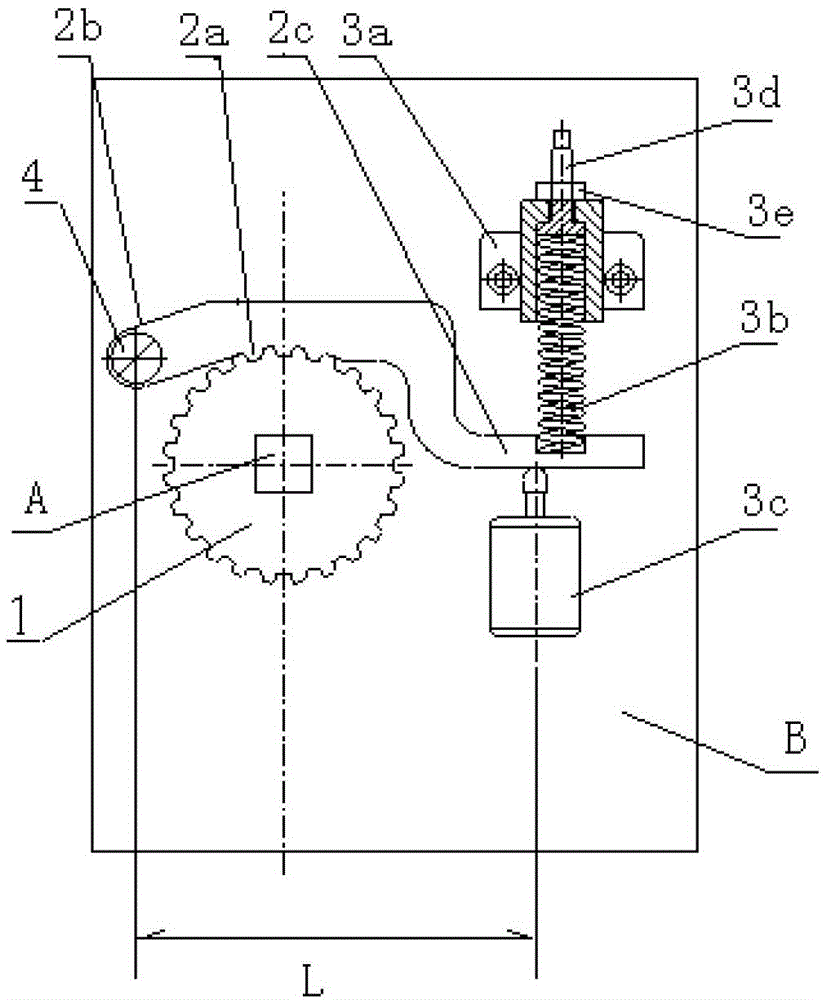

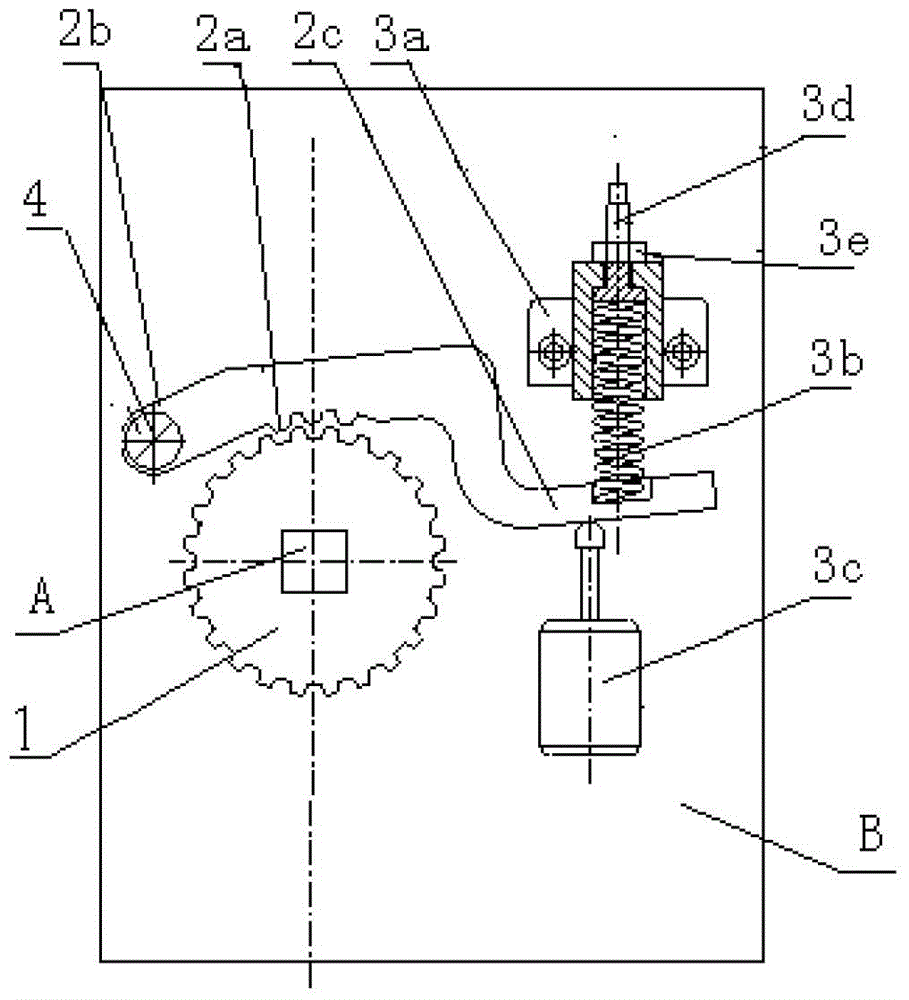

[0019] Figure 1 ~ Figure 3 It is an embodiment of the present invention.

[0020] This embodiment is installed on a vehicle-mounted automatic leveling mechanism for automatic locking of the rotating shaft of the leveling mechanism during transportation. The maximum rotational moment of the rotating shaft is 30N·m, the minimum locking angle is 15°, and the locking position accuracy is ± 10'.

[0021] Such as figure 1 , figure 2 , image 3 As shown, wherein A is the rotary shaft to be locked, and B is the fixed frame of the rotary shaft. A toothed rotary automatic locking mechanism of the present invention installs a coaxial toothed shaft 1 on the rotary shaft, and a locking plate 2 has locking teeth 2a matching the teeth on the toothed shaft 1, the head end 2b of the locking plate 2 is hinged on the support frame of the rotary shaft, the control h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com