Gear adjusting gasket and differential

A technology for adjusting shims and differentials, which is applied to belts/chains/gears, transmission parts, mechanical equipment, etc., and can solve the problems of complex gear clearance adjustment, low differential failure rate, and long service life. Conducive to cooling and heat dissipation, long service life and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

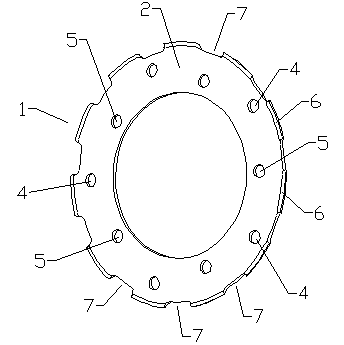

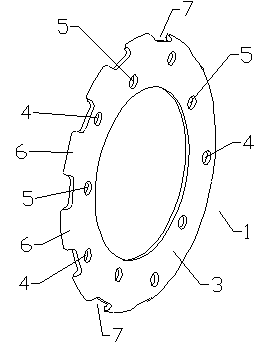

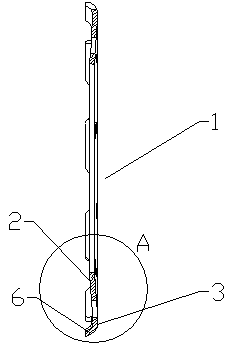

[0024] Examples such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a gear adjusting gasket, the adjusting gasket 1 is annular, the adjusting gasket 1 has an inner surface 2 and an outer surface 3, the adjusting gasket 1 has an inclination angle α inclined to the outer surface 3, and can be used at any time Adjust the tooth side clearance of the meshing gears. The inclination angle α makes the gears always bound to the center along the axis to ensure the tooth side clearance. The adjustment gasket 1 has versatility, and there is no need to select the thickness and structure of the gasket according to the tooth side clearance and gear meshing conditions. At the same time, the gear meshing state is improved, thereby reducing vibration and noise.

[0025] The following describes the application of the adjusting shim in combination with the differential, such as Figure 5 As shown, the differential includes a differential case 8, a gear 9 is arranged in the differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com