Cold Storage Refrigerator

A refrigerator and cold storage technology, which is applied in the direction of refrigerators, gas cycle refrigerators, refrigeration components, etc., and can solve the problem of increased loss of working gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, embodiments of the present invention will be described with reference to the drawings.

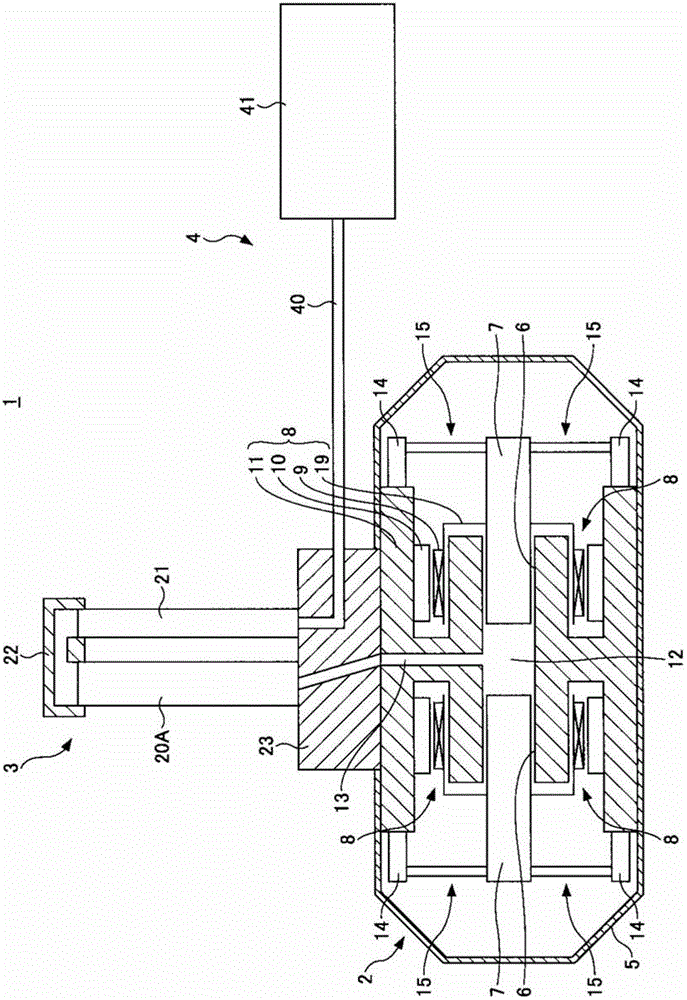

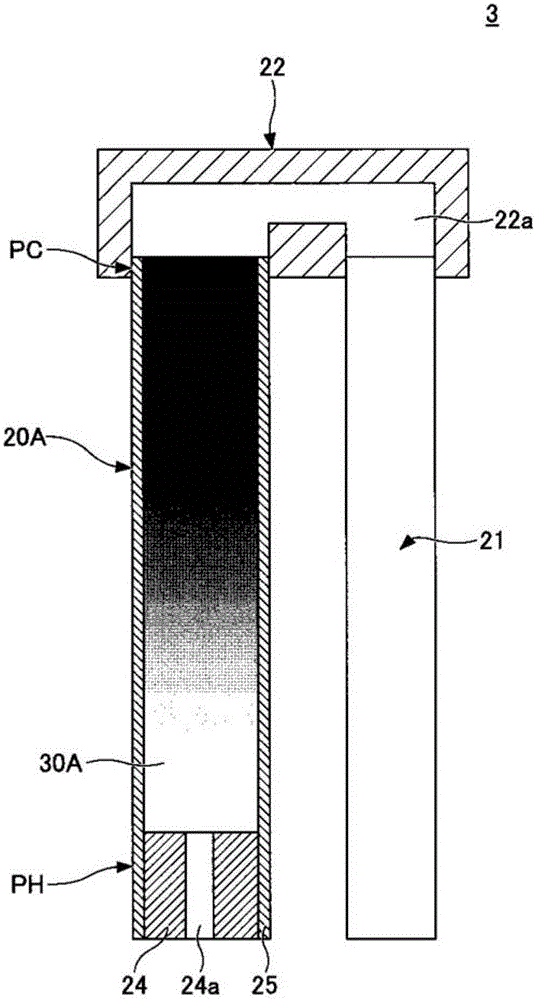

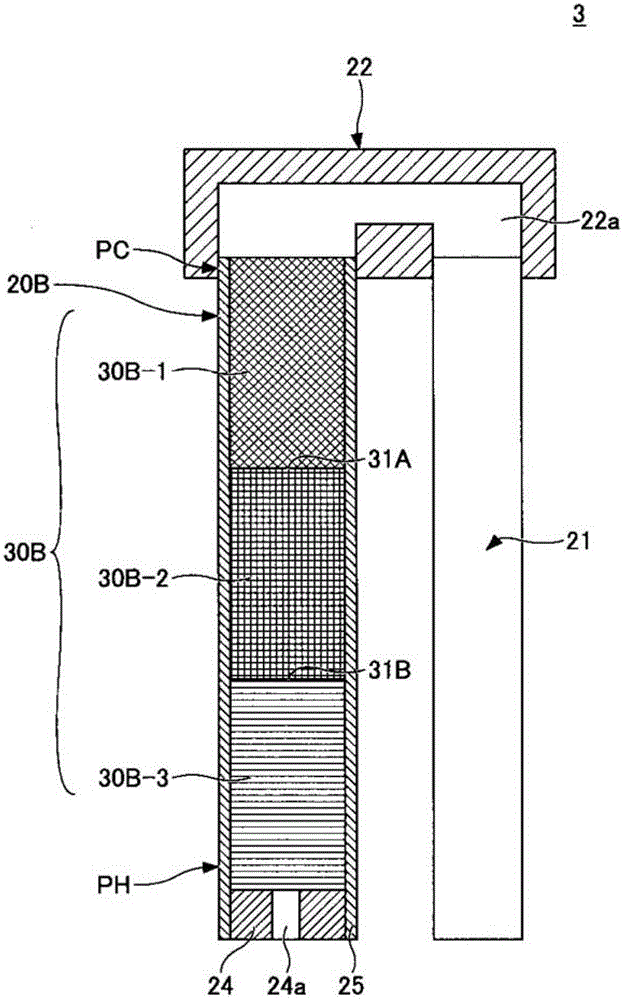

[0024] figure 1 The regenerative refrigerator which is the first embodiment of the present invention is shown. In this embodiment, a Stirling-type pulse tube refrigerator 1 (hereinafter, simply referred to as a refrigerator) will be described as an example of a regenerative refrigerator. This refrigerator 1 roughly includes a compressor 2 , an expander 3 , and a phase control unit 4 .

[0025] The compressor 2 is configured such that a cylinder 6 , a piston 7 , a linear motor 8 , a leaf spring unit 15 , and the like are provided inside a casing 5 .

[0026] The cylinder 6 is provided at the center of the housing 5 to extend in the left-right direction in the drawing. A pair of opposed pistons 7 are disposed inside the cylinder 6 . The piston 7 is configured to be able to move axially ( figure 1 left and right direction) for linear reciprocating movement. A compression ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com