Novel burning-through point forecasting technology

A new technology of sintering end point, applied in the field of new sintering end point prediction, can solve the problems of difficult to accurately determine the sintering end point, difficult to ensure the operator's judgment, lack of global consistency, etc., to achieve the effect of reliable sintering control information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] New sintering end point estimation technology, step 1: calculate the basic exhaust gas temperature curve, the specific method is: install a thermocouple in each sintering bellows to measure the exhaust gas temperature in the bellows, take the exhaust gas temperature in the bellows as the longitudinal Coordinates, the position of the bellows of the trolley is the abscissa, and the basic temperature curve is fitted with multiple interpolation algorithms; after testing, the curve fitted by the multiple spline interpolation algorithm is smoother and more accurate than other algorithms, such as least squares method, Gaussian algorithm, Fourier Leaf series curve fitting method.

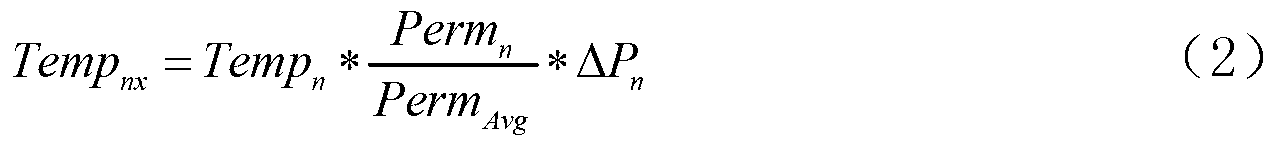

[0018] Step 2: Correct the basic temperature curve based on the bellows pressure and gas permeability information. The specific method is: (1) The first step is to measure the pressure in the furnace and the bellows and calculate the gas permeability, and install the pressure in the ignition furnace a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com