Shearing box device for rock-like material

A technology of shear box and rock quality, which is applied in the directions of measuring devices, analyzing materials, and testing the strength of materials by applying stable shear force, which can solve the problem of reducing the universality and applicability of shear test results and reducing the accuracy of test results and reliability, and rock-like materials have not been seen yet, to achieve the effect of reducing the displacement of the upper and lower shear boxes, meeting engineering requirements, and being easy to use and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

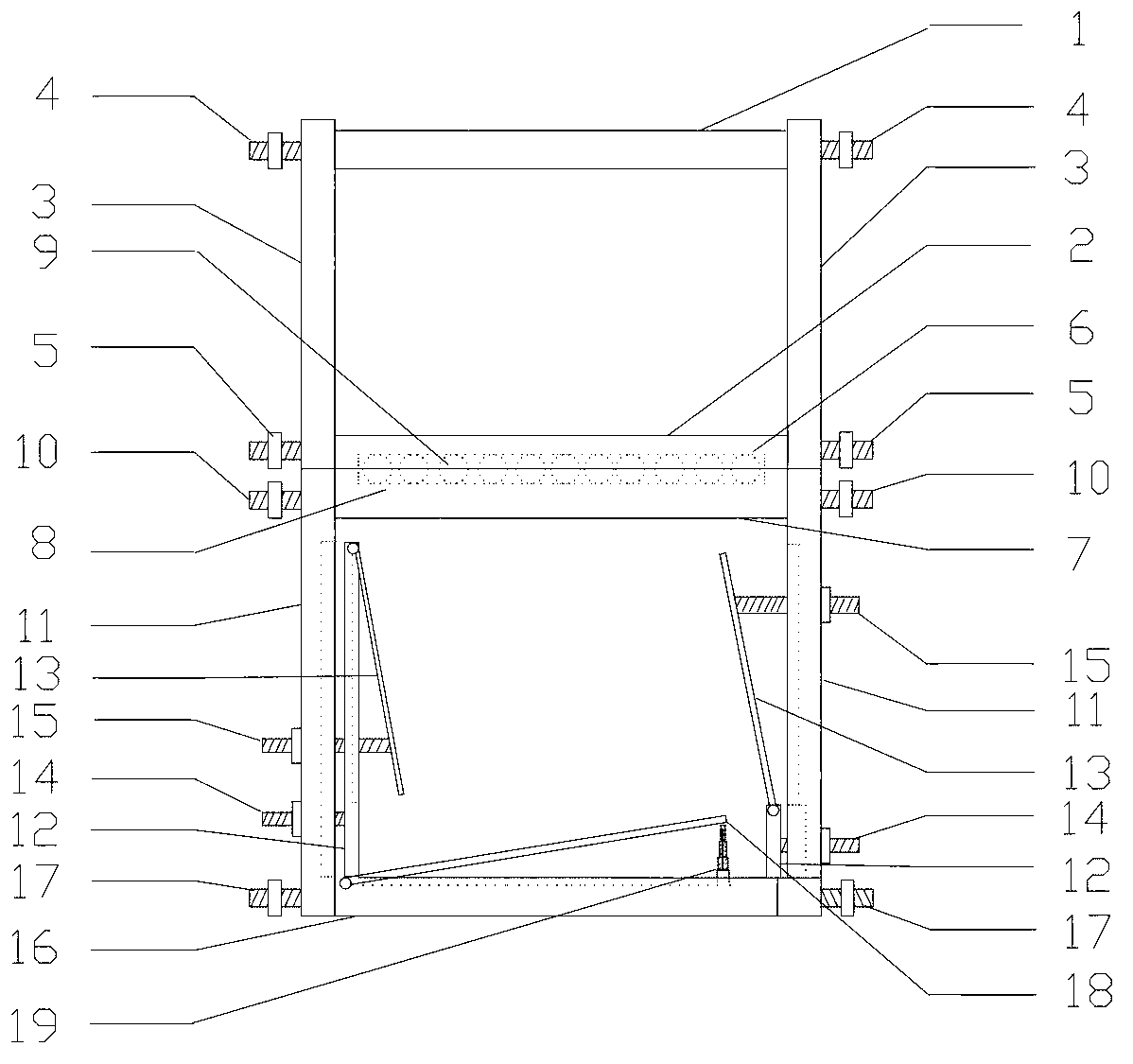

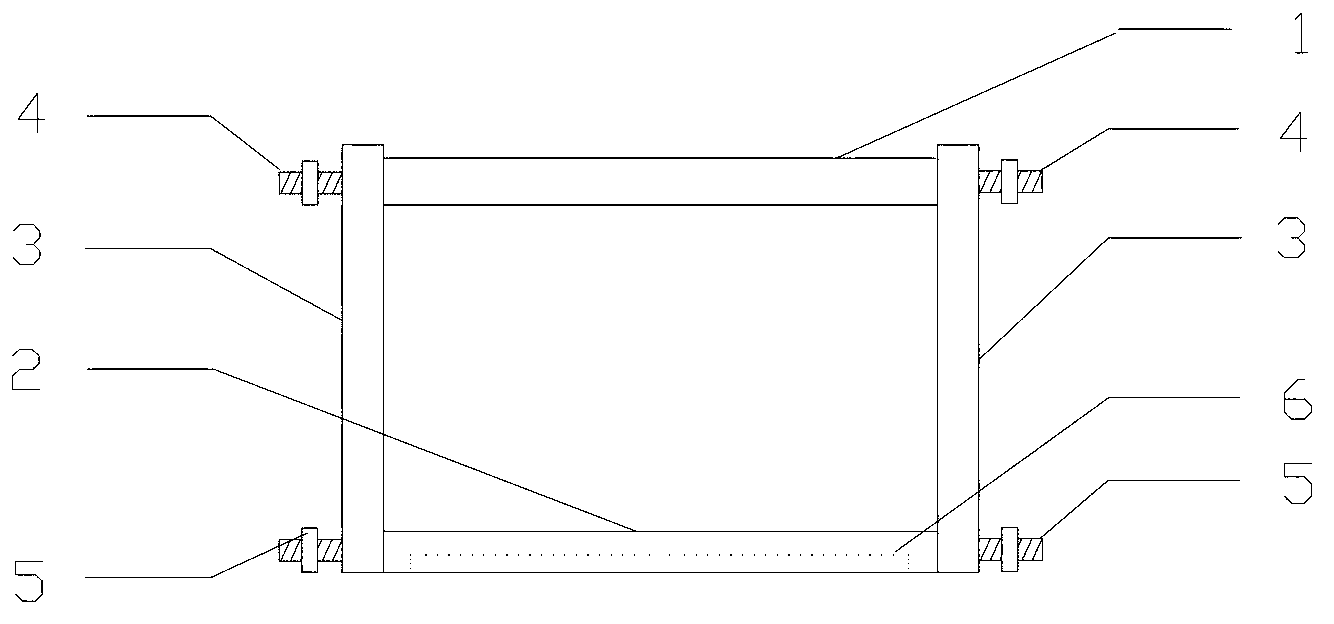

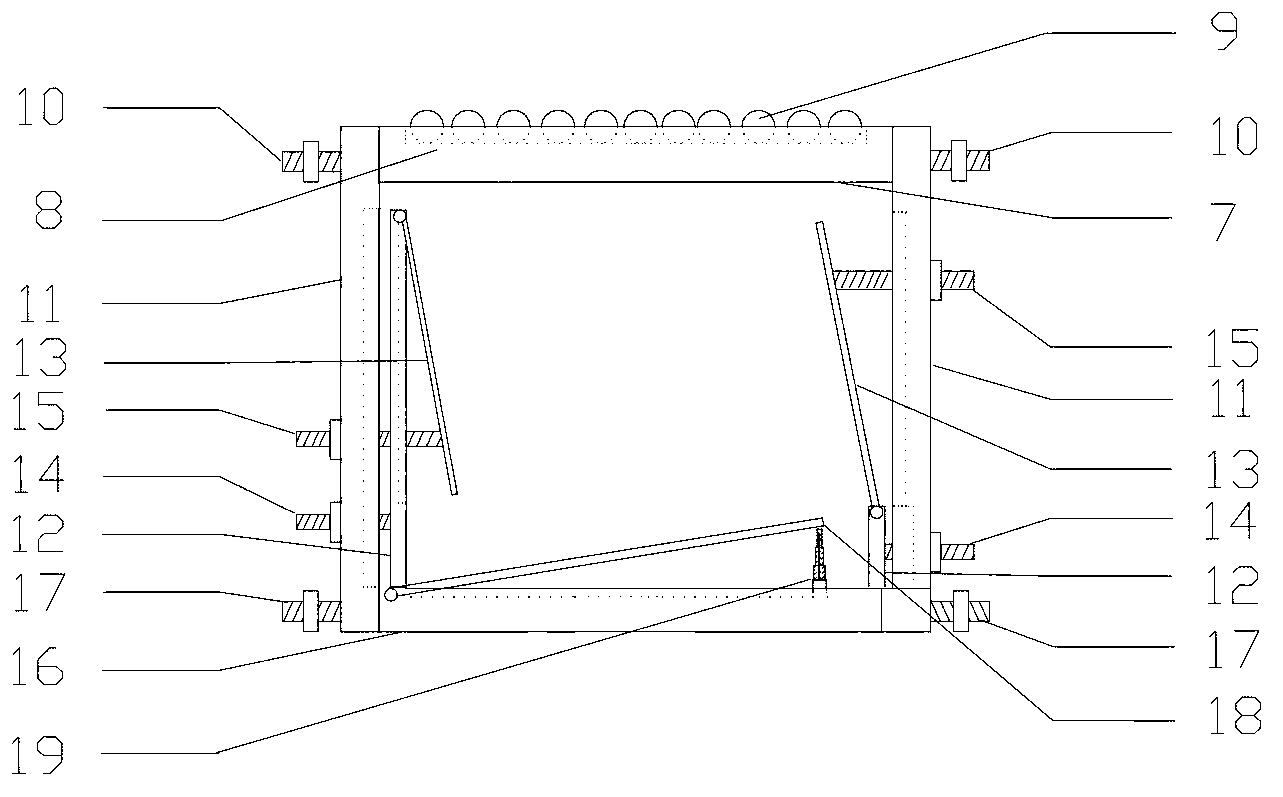

[0014] The main structure of the improved shearing box device involved in this embodiment is a shearing box device with an integrated square structure composed of two functional structures of the upper shearing box and the lower shearing box; wherein, the upper shearing box Including upper box top 1, upper box bottom 2, upper box movable part 3, upper box top fixing bolt 4, upper box bottom fixing bolt 5 and upper box bottom fixing groove 6, upper box top 1 is a plate Type steel plate structure, the bottom 2 of the upper box is a column structure; the movable part 3 of the upper box is a plate-shaped steel structure, the movable part 3 of the upper box is located on both sides of the upper box, and the fixing bolt 4 on the top of the upper box is connected with the upper box The top 2 is fixedly connected symmetrically, and is fixedly connected with the bottom 2 of the upper box through the fixing bolts 5 at the bottom of the upper box. Through the position change of the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com