Mechanism for enveloping polar groups and feeding polar groups into groove

A coating and pole group technology, applied in the field of coating tank entry mechanism, can solve problems such as unqualified, affecting work efficiency, pole group pollution, etc., achieve good coating effect and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

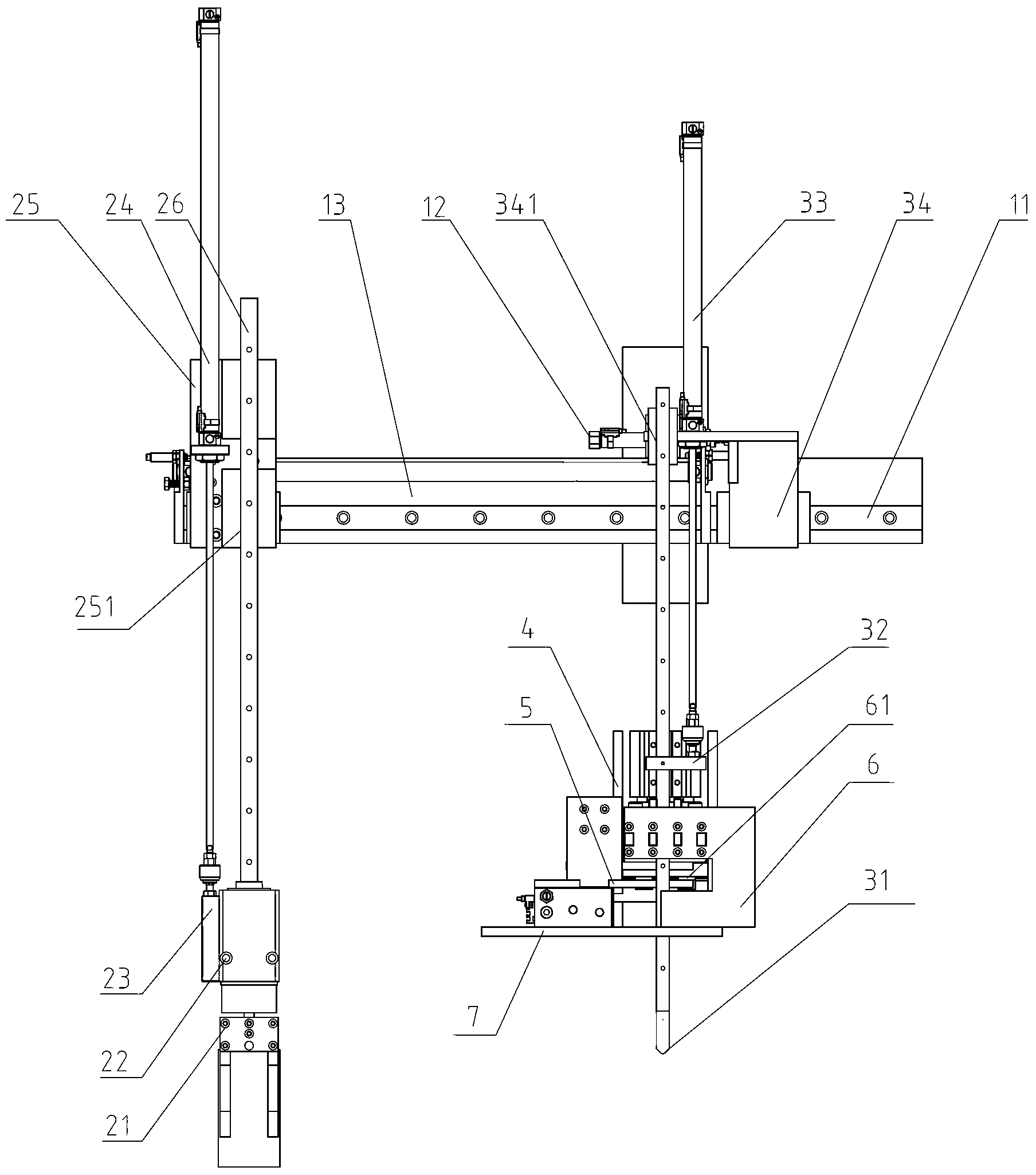

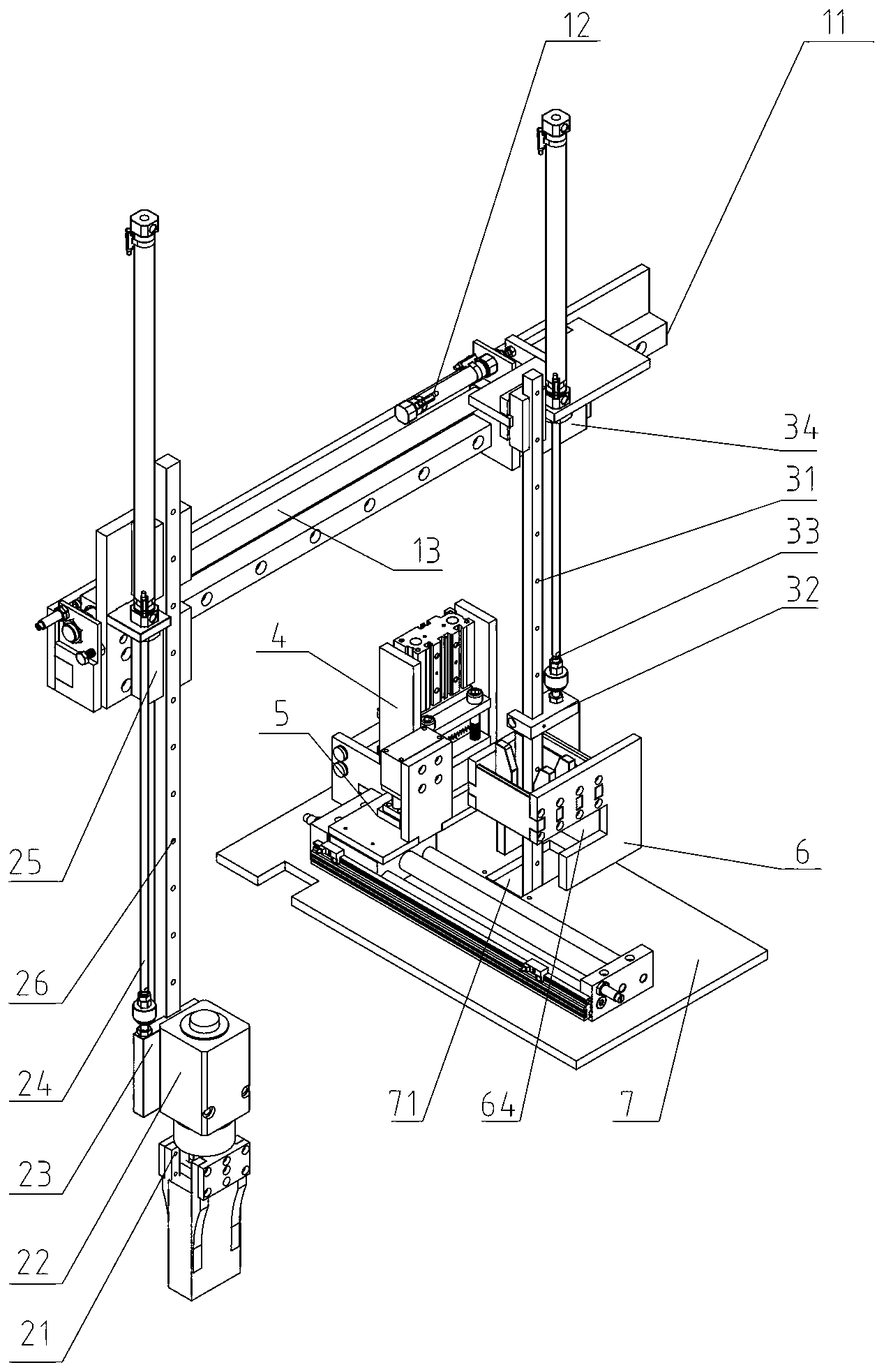

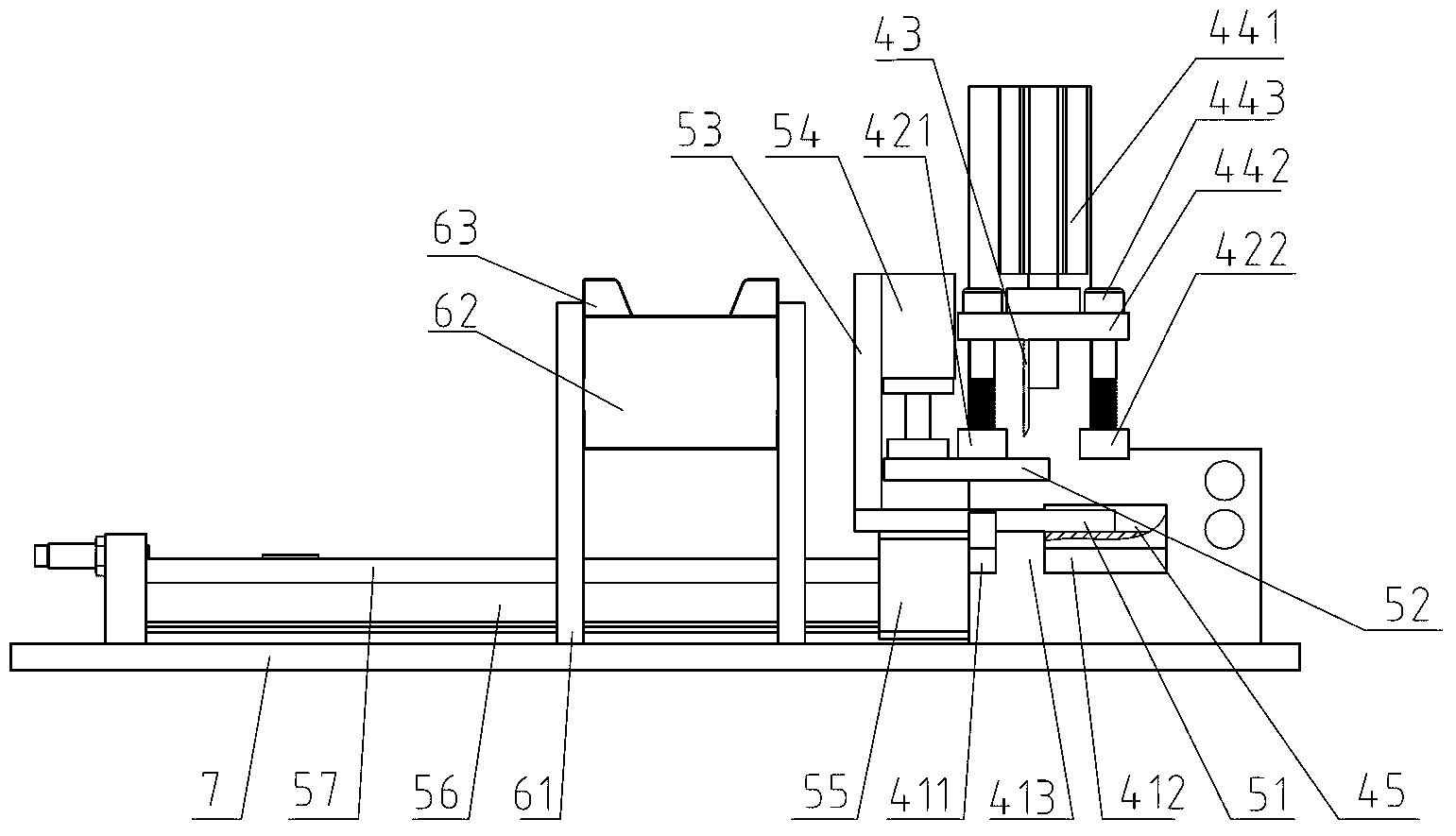

[0022] The present invention provides an extremely group coating film feeding groove mechanism, which includes a feeding device and a film feeding device. The film feeding device includes a film cutting component, a film support plate and a film take-up member arranged above the film support plate and movable along the film support plate. , The film support plate is provided with a film opening, and a clamping rack is set directly above the film opening. The clamping rack is equipped with an avoiding groove for avoiding the film removal. The feeding device includes a clamping material that transfers the pole group to the clamping rack. The arm, the push rod that pushes the pole group on the clamping rack into the envelope port; setting a clamp under the envelope port can realize the pole group envelope and the slot, the pole group transfer and the slot pass through two different Mechanisms that cooperate with each other can improve work efficiency, and the pole group can be comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com