Battery packaging piece trough entering machine

A slotting machine and storage battery technology, applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of long time spent and low mechanical efficiency, achieve good results and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

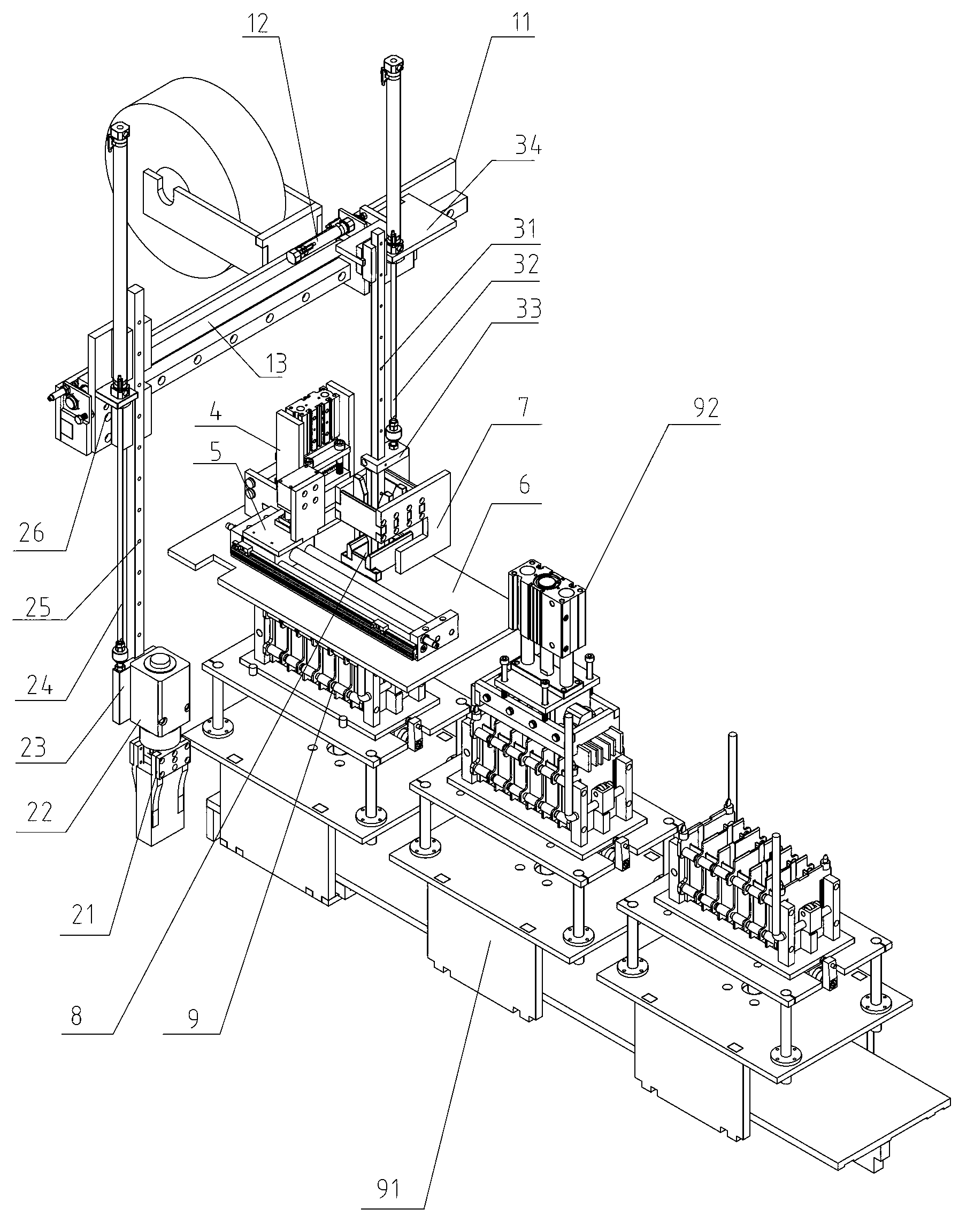

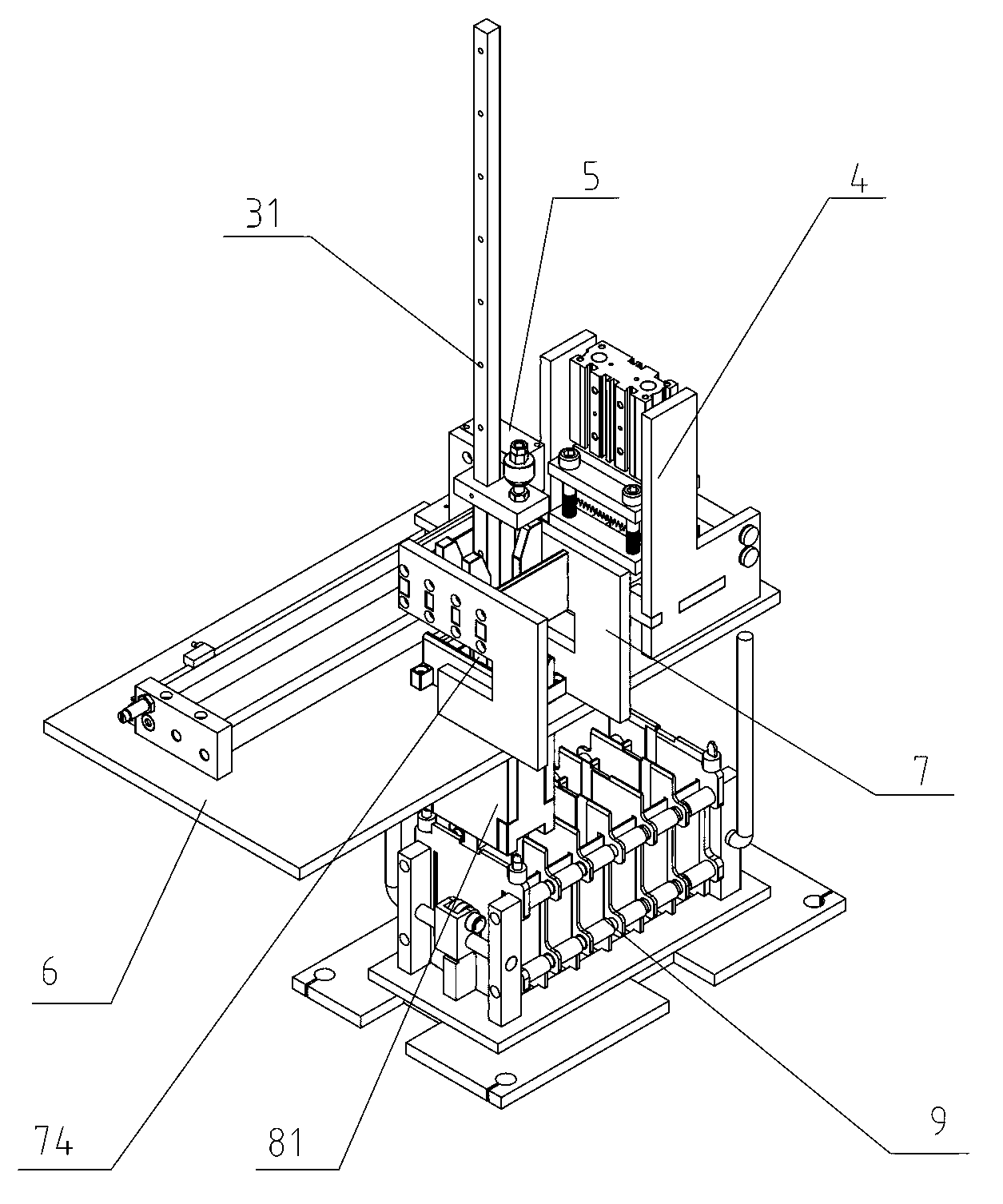

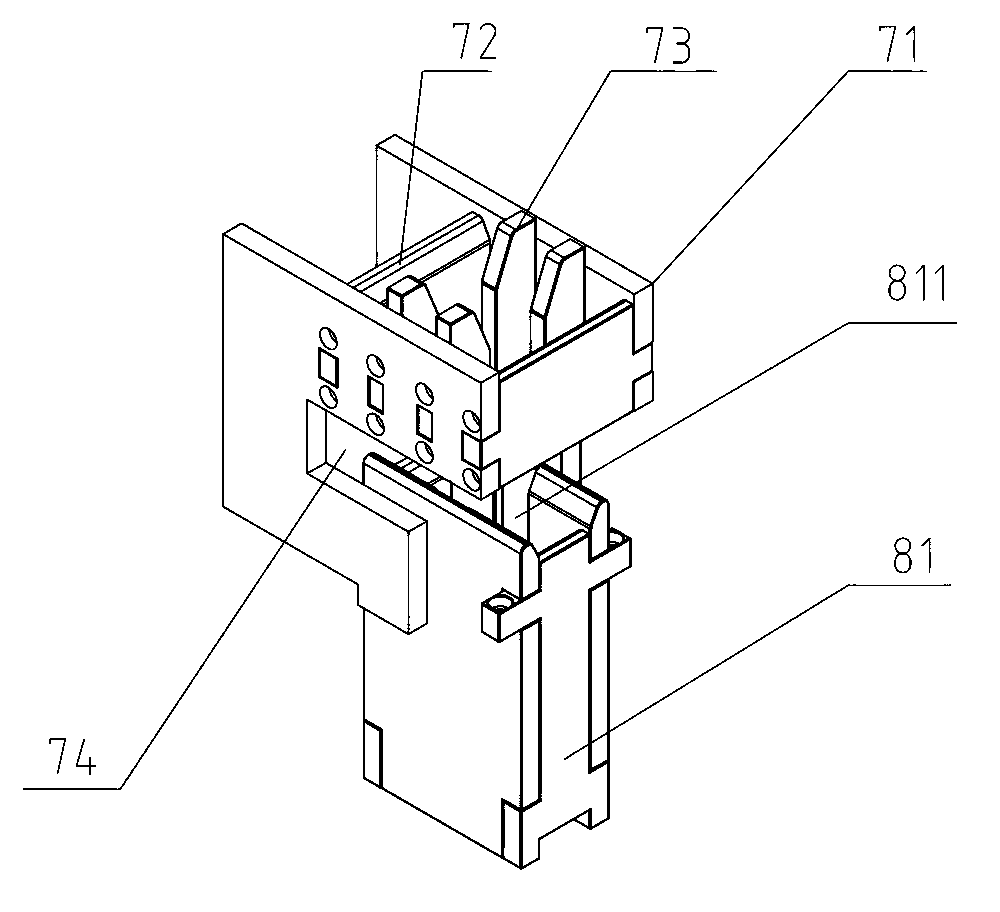

[0024] The invention provides a slotting machine for battery pack slices, which includes a feeding device, a film feeding device, a casting and welding jig and a sliding seat that drives the casting and welding jig to move laterally. The component and the film taking part that can be moved laterally, the film support plate is provided with a coating port, the clamping frame is provided above the film port, and the clipping frame is provided with an avoidance groove for avoiding the lateral movement of the film taking part. The casting and welding fixture is set directly below, and the feeding device includes a clamping arm that can transfer the pole group to the clamping rack and a push rod that pushes the pole group in the clamping rack into the casting and welding fixture along the coating mouth; through this device Automatic coating and slotting, and the transfer of the pole group and coating into the slot are completed by different components, which can make full use of tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com