Veress needle

A technique of Veress needle and needle tip, which is applied in the field of Veress needle, which can solve the problems of poor workability, organ damage, and difficulty in preventing the needle tip from falling off, and achieve the effect of good workability and easy fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

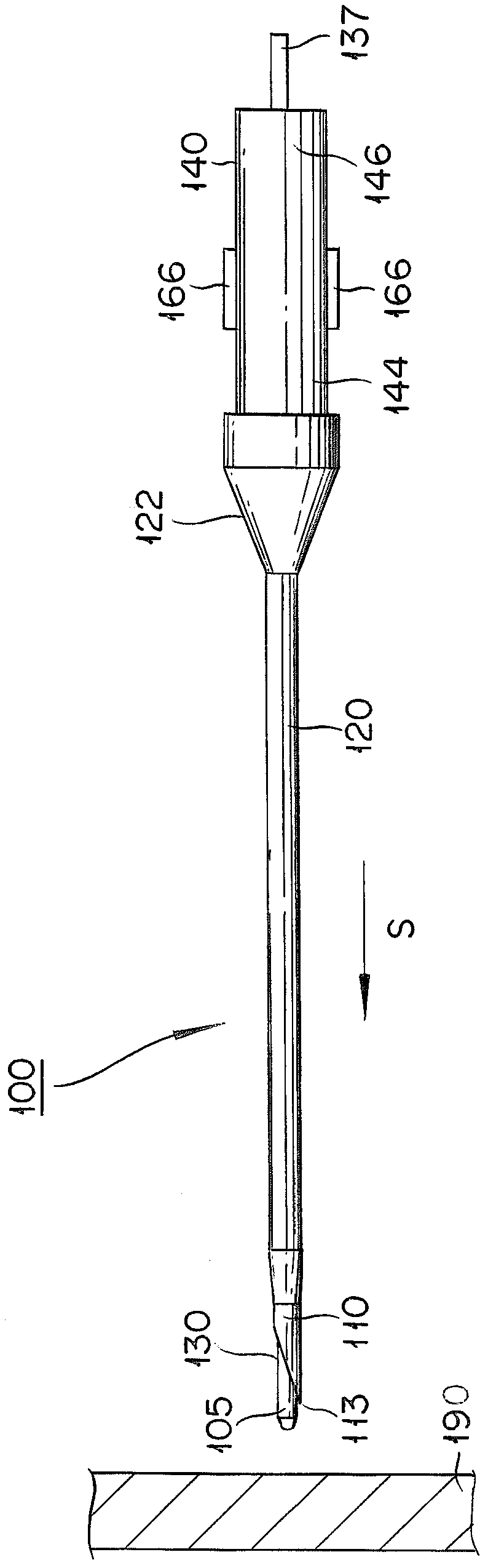

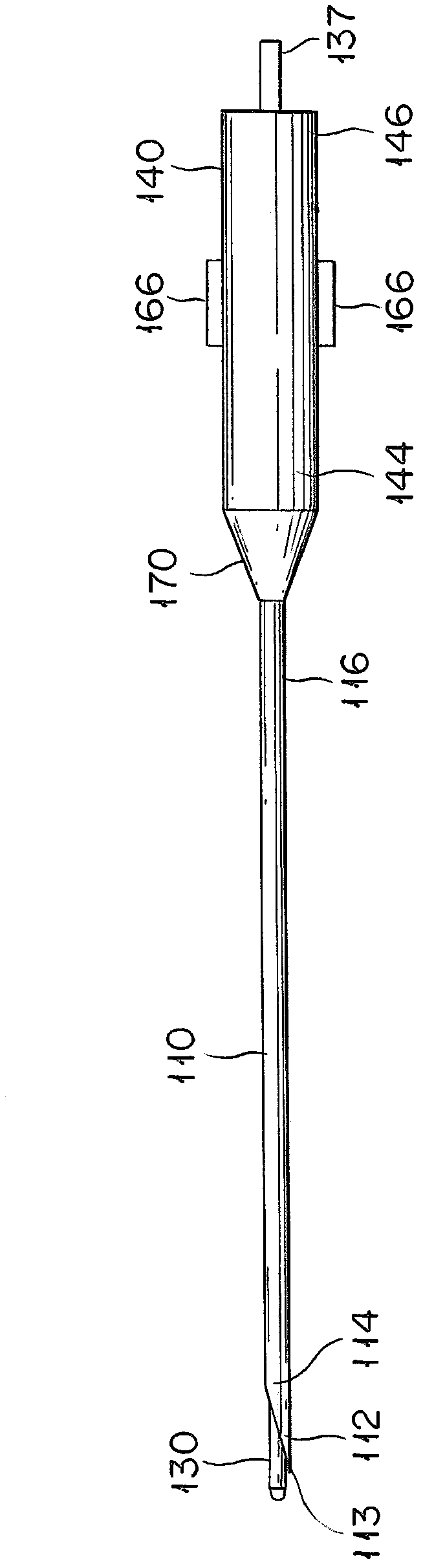

[0050] The Veress needle 100 involved in Embodiment 1, such as figure 1 As shown, it has a puncture needle 110 , an outer sleeve 120 , an insertion member 130 , a drop prevention mechanism 105 , and a hand operation unit 140 , and the Veress needle 100 is used to puncture a wall 190 in a living body. When applied to transvaginal hydrolaparoscopy (THL: Transvaginal hydrolaparoscopy), the wall portion 190 is a vaginal wall. The wall portion 190 is not limited to the vaginal wall, but can also be applied to the abdominal wall.

[0051] The puncture needle 110 is composed of a hollow tube, and has a front end 114 formed with a sharp needle point 112 and a base end 116 connected with a needle hub 170 (refer to image 3 ). The needle hub 170 is hollow and is used to connect the base end 116 of the puncture needle 110 to the hand operation part 140 .

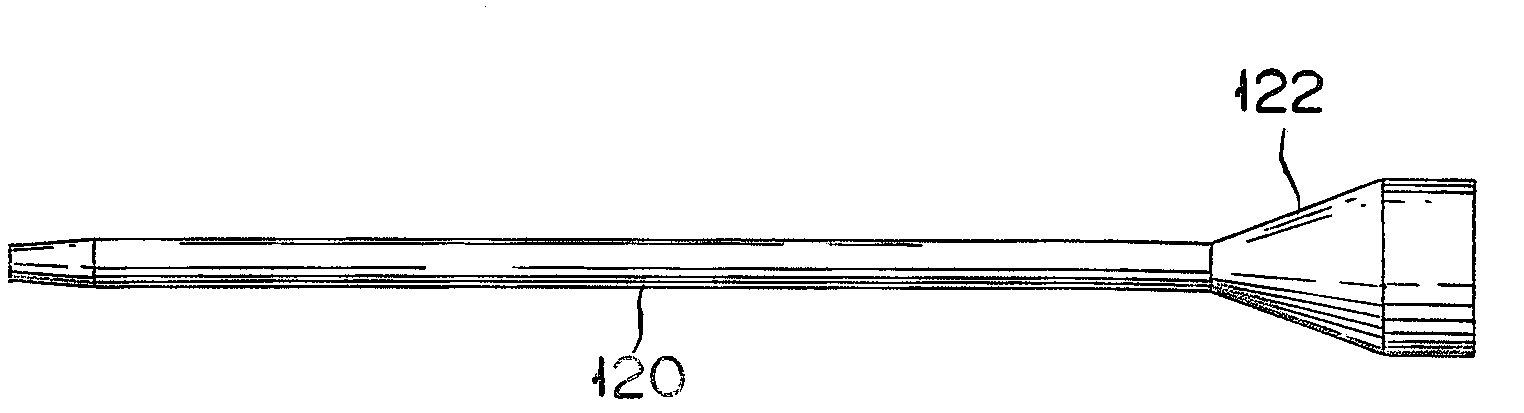

[0052] Outer sleeve 120 (refer to figure 2 ) has: an inner cavity 128 for the insertion of the puncture needle 110 (refer to F...

Embodiment approach 2

[0093] Embodiment 2 is substantially different from Embodiment 1 in that the extension of the wire is used for the fall-off prevention mechanism.

[0094] Specifically, the insertion member 130A is hollow and has an inner cavity 138 in which the wire (second insertion member) 180 is disposed. The front end portion 134 of the insertion member 130A is closed, and a side opening portion 139 communicating with the lumen 138 is formed. The wire 180 has a front end 184 connected to the closed portion of the front end 134 , and a base end 186 passing through the lumen 138 and extending to the outside of the hand operation part 140 .

[0095] The front end portion 184 of the wire 180 has a curved shape, is inserted into the lumen 138 of the insertion member 130A in an elastically deformed state, and is configured to be inserted from the inside of the puncture needle 110 after the load caused by the puncture disappears. The side opening 139 of the insertion member 130A protruding from...

Embodiment approach 3

[0099] Embodiment 3 differs from Embodiment 1 in that the outer sleeve is not provided, the insertion member is formed of a guide wire, and the guide wire can be reliably left at the puncture site.

[0100] Specifically, the Veress needle according to Embodiment 3 includes a puncture needle 110B, an insertion member 130B, a fall-off prevention mechanism 105B, and a hand operation unit 140B.

[0101] The puncture needle 110B has a base end portion 116 to which a needle hub 170B is connected. The needle hub 170B is detachably attached to the hand operation part 140B.

[0102] Insertion member 130B has base end portion 136B extending inside operation portion 140B at hand. The base end portion 136B is fixed with a detachable fixed connector 172B constituting an expansion portion protruding in a direction intersecting the axial direction S of the insertion member 130B.

[0103] The fixed connector 172B is an expanded portion of a base end portion of an insertion member formed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com