Disc type ditching and grass burying all-in-one machine

A disc-type, all-in-one technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of time-consuming and labor-intensive, and achieve the goal of improving quality, reducing ditching depth, and reducing power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing.

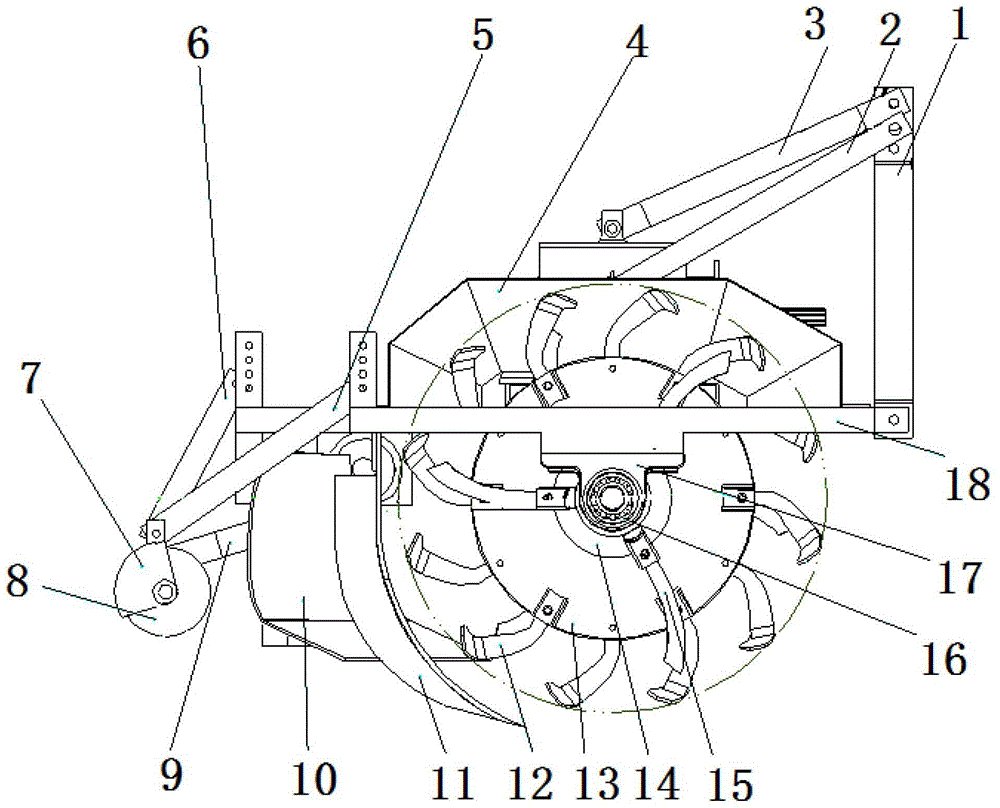

[0025] Such as figure 1 Shown, this invention mainly is made up of universal transmission, suspension system, frame 18, gear transmission case 19, ditching parts, burying grass plow 10 and covering mechanism etc. The suspension system adopts a three-point rear suspension, which is mainly composed of a suspension arm 1, a rear suspension arm 2 and a suspension support rod. Ditching part mainly is made up of rotary cultivating knife 13, main cutter head 14, wall cutting cutter head 15, wall cutting knife 16, bearing 17 and bearing seat 18. The action of burying the grass is mainly completed by the plow 10 of burying the grass. The soil-covering mechanism is mainly composed of soil-covering cover 7, soil-covering shaft 8, soil-covering shaft pull rods 5 and 6, soil-covering shaft support rods 9 and other parts.

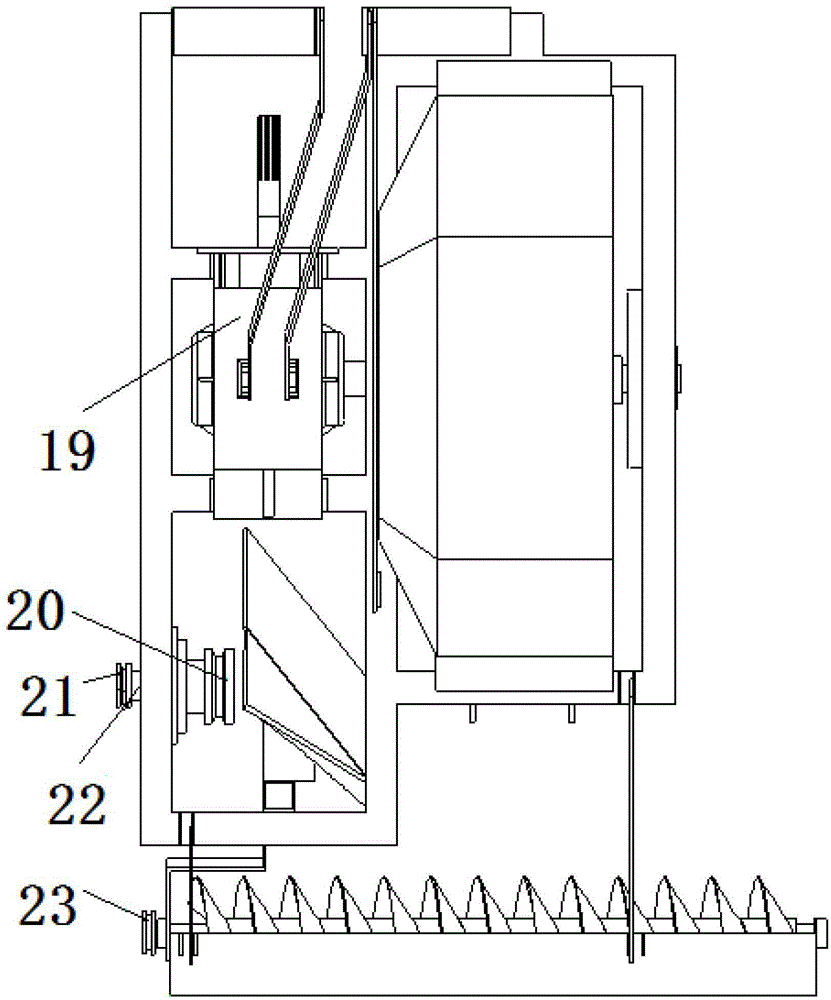

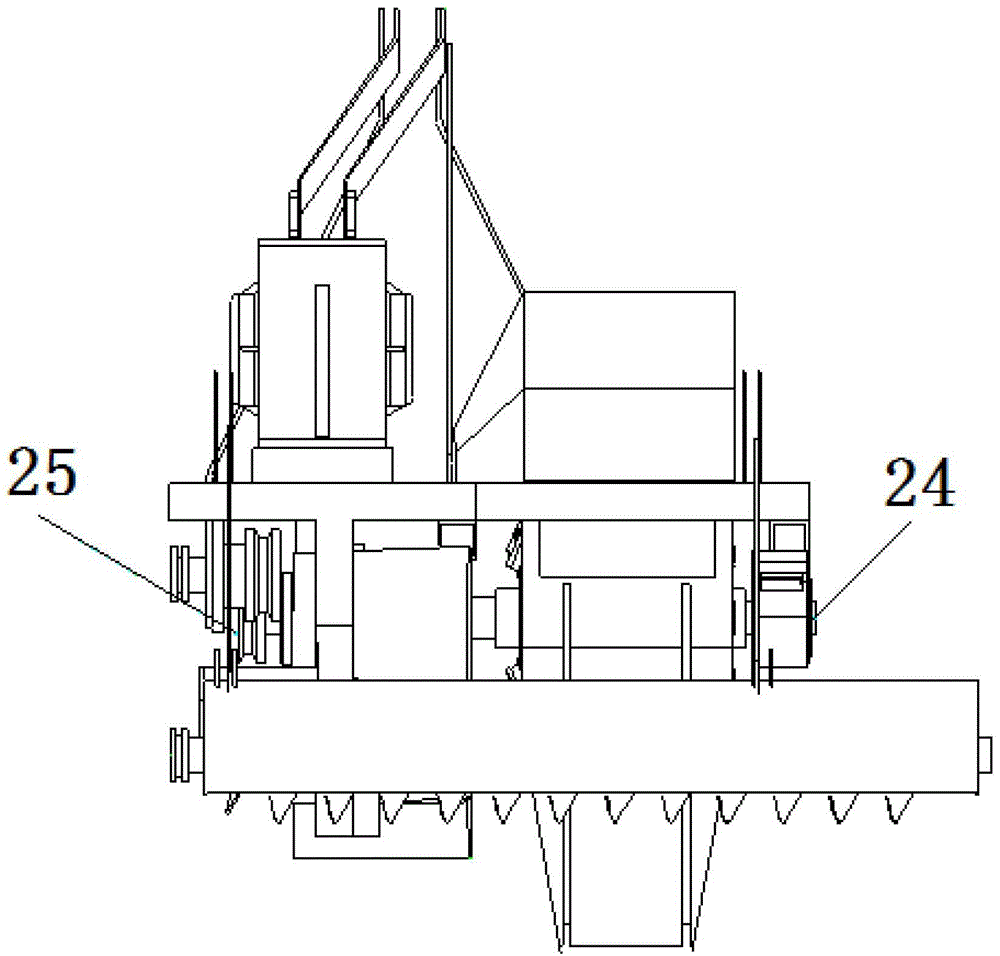

[0026] The drive system of the machine is as Figure 4 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com