An Electron Beam Welding Method for Irregular Curved Surfaces

A technology of electron beam welding and special-shaped curved surface, applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low efficiency, difficult quality assurance, poor welding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

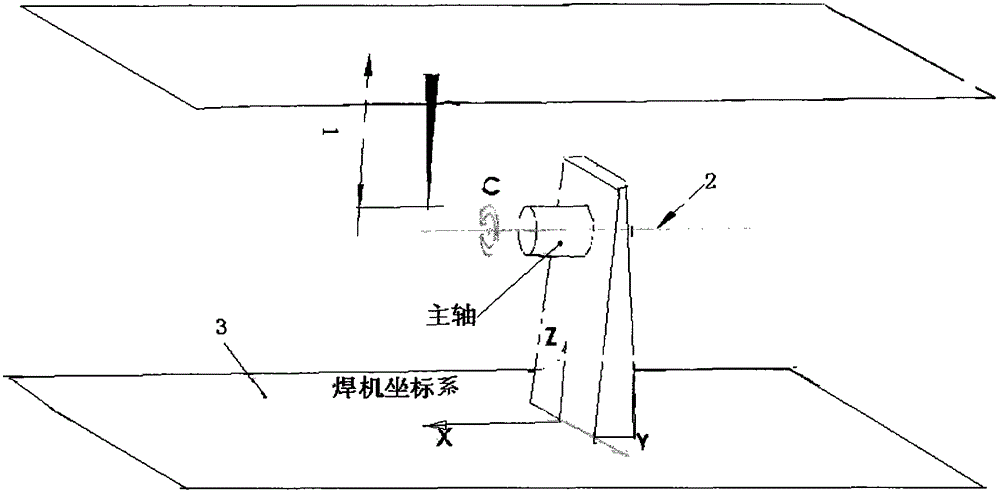

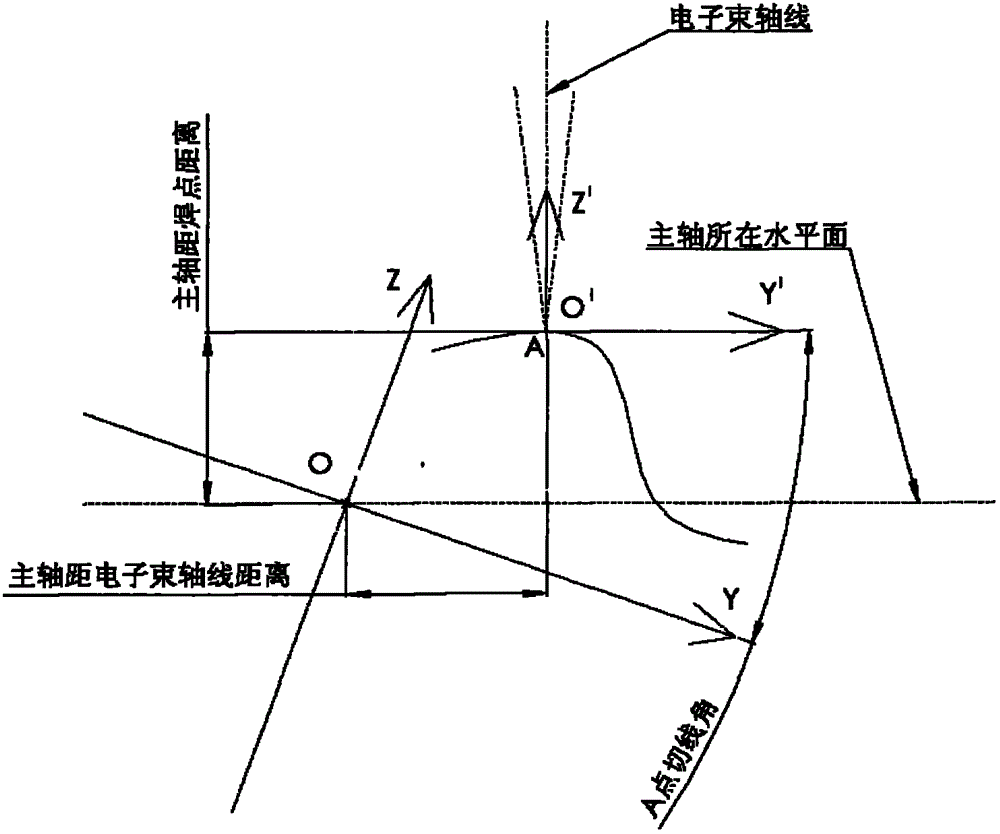

[0047] An electron beam welding method for a special-shaped curved surface, comprising the steps of:

[0048] Step 1: Establish welding seam trajectory curve

[0049] After the three-dimensional model of the part to be welded is designed (that is, before the product is not processed and welded), the weld plane curve can be established according to the track of the weld to be welded. This step is realized by using existing technology.

[0050] Step 2: Curve Decomposition

[0051] Decompose the curve according to the characteristics of the curve. The decomposition principle is to decompose it into straight line segments and arc segments according to the weld track curve, that is, the weld track curve is composed of multiple consecutive straight line segments and arc segments, and the number of segments to be decomposed is as small as possible. .

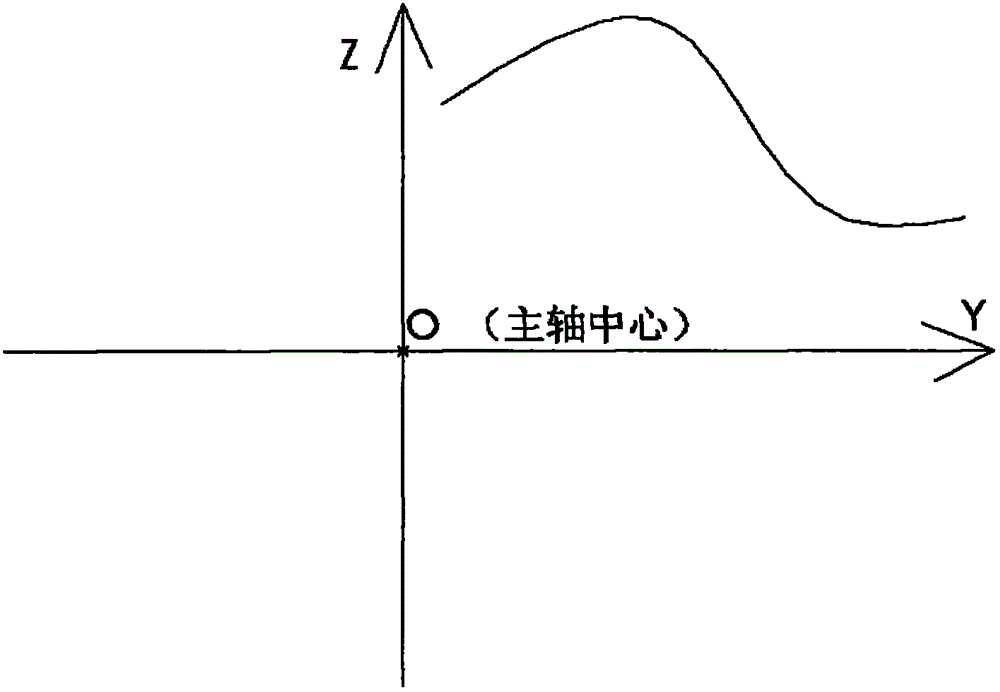

[0052] Step 3: Collect points and solve

[0053] The following points are collected for each segment of the curve decomposed in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com