Lampshade automatic laminating mechanism

A pressing mechanism and automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of product quality and appearance consistency, difficulty in meeting production capacity requirements, and increased production costs, so as to achieve uniform force, Quick and accurate fastening, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

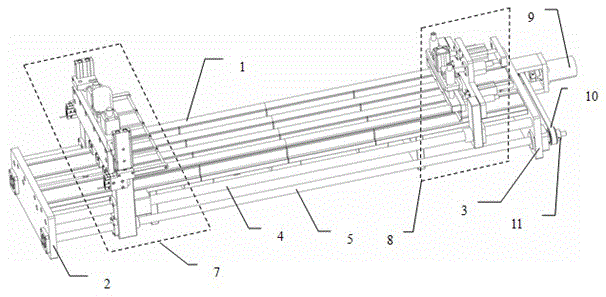

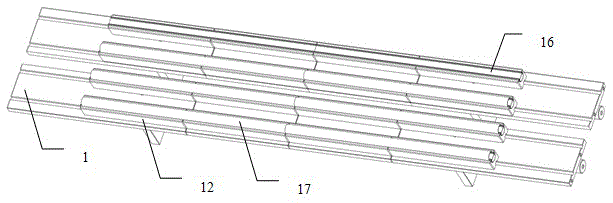

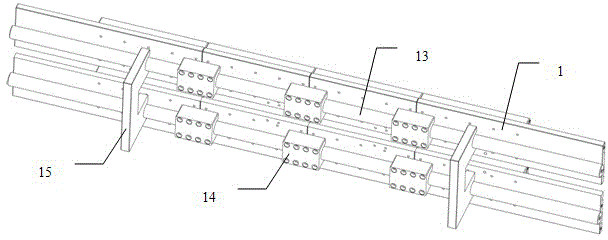

[0024] see figure 1 , figure 2 , Figure 4 , Figure 6 and Figure 7 , an automatic lampshade pressing mechanism, comprising: a support plate group 1, a support groove 12 fixed on the upper surface of the support plate group 1, a first baffle plate 2 and a second baffle plate fixed at both ends of the support plate group 1, The horizontal guide bar 4 connecting the first baffle plate 2 and the second baffle plate 3, the rolling die set 7 and the positioning die set 8 sleeved on the horizontal guide bar 4 pass through the rolling die set 7 The first bearing 701 and the first ball screw 5 that connects the first and second baffles 3 pass through the bearing of the positioning module 8 and connect the second ball of the second baffle 3 screw 6, the first motor 9 arranged outside the second baffle 3, the synchronous pulley 11 sleeved on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com