Automobile tyre explosion-proof support device

A support device and technology for automobile tires, applied in tire parts, vehicle parts, transportation and packaging, etc., can solve problems such as unfavorable operation and cumbersome and complicated installation process, and achieve strong support stability, wide application range and rapid response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

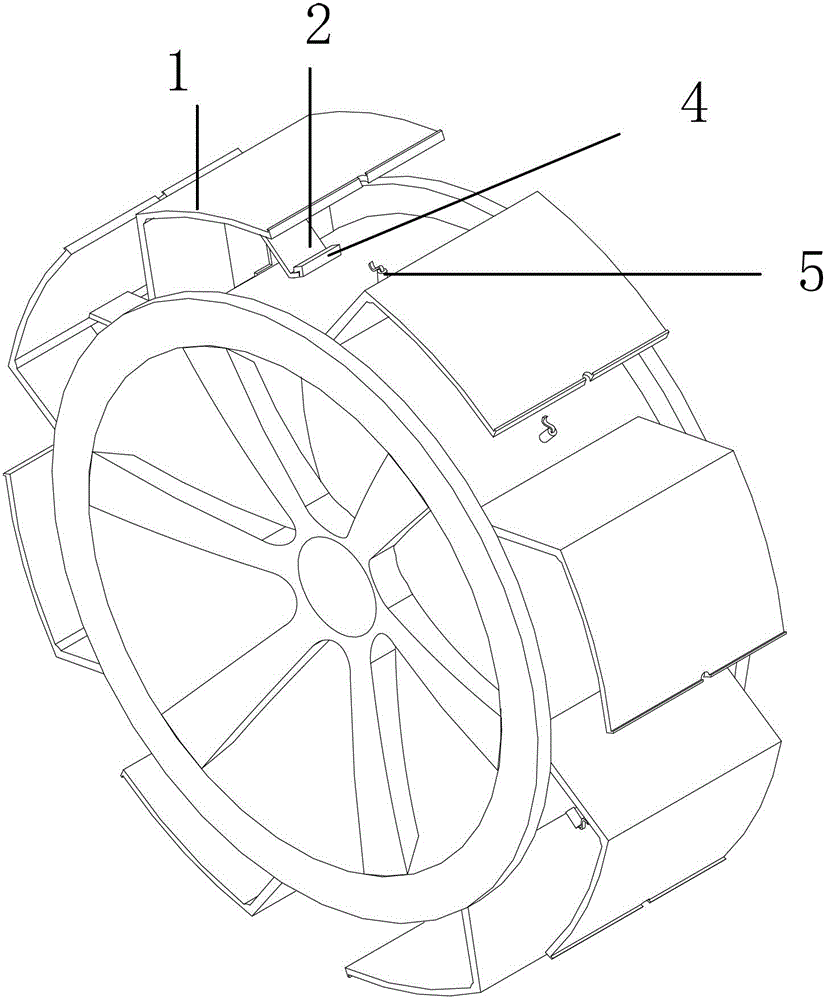

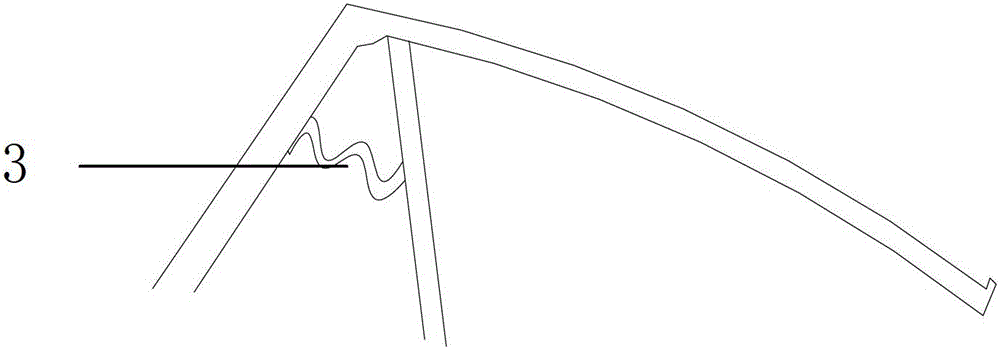

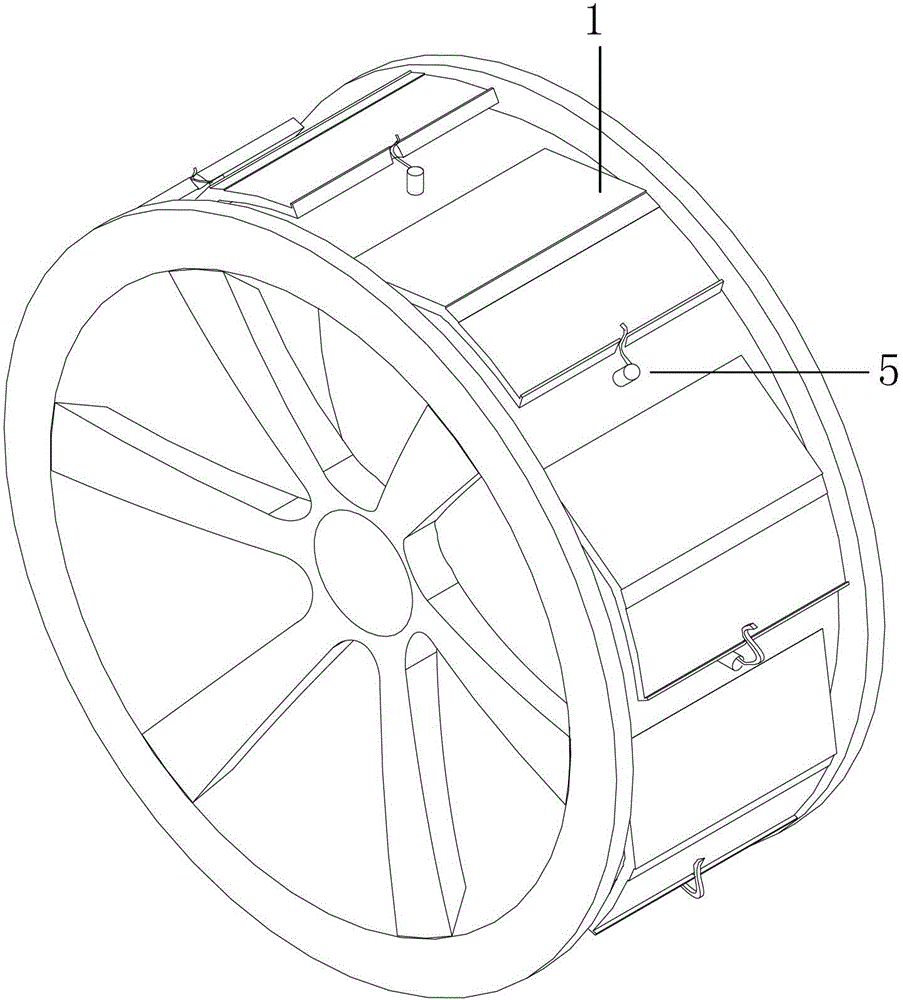

[0014] combine Figure 1~3 , the present invention is mainly made up of components such as arch piece 1, slide block 2, spring block 3, C-shaped sleeve 4, movable block 5. The arched piece is composed of a straight line part at the bottom and an arc-shaped part at the top, and the two parts are directly formed by an integral steel sheet or alloy sheet. The bottom end of the arched piece is fixed on the wheel hub with bolts, the middle part is connected with the sliding piece by a spring, and the upper part forms a circular support device to ensure that the tire can still continue to run after a blowout. The sliding block is connected with the middle part of the arched piece by a spring, and its top is hinged with the arched piece so that the movable block can be opened quickly. When the sliding block moves, the arched piece can be opened to form a circular suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com