Spinner

A technology of wrapping head and coil core, applied in transportation and packaging, electrical components, transportation of filamentous materials, etc., can solve problems such as troublesome belt angles, and achieve the effect of not easy to loosen, good safety performance, and time-saving and labor-saving adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

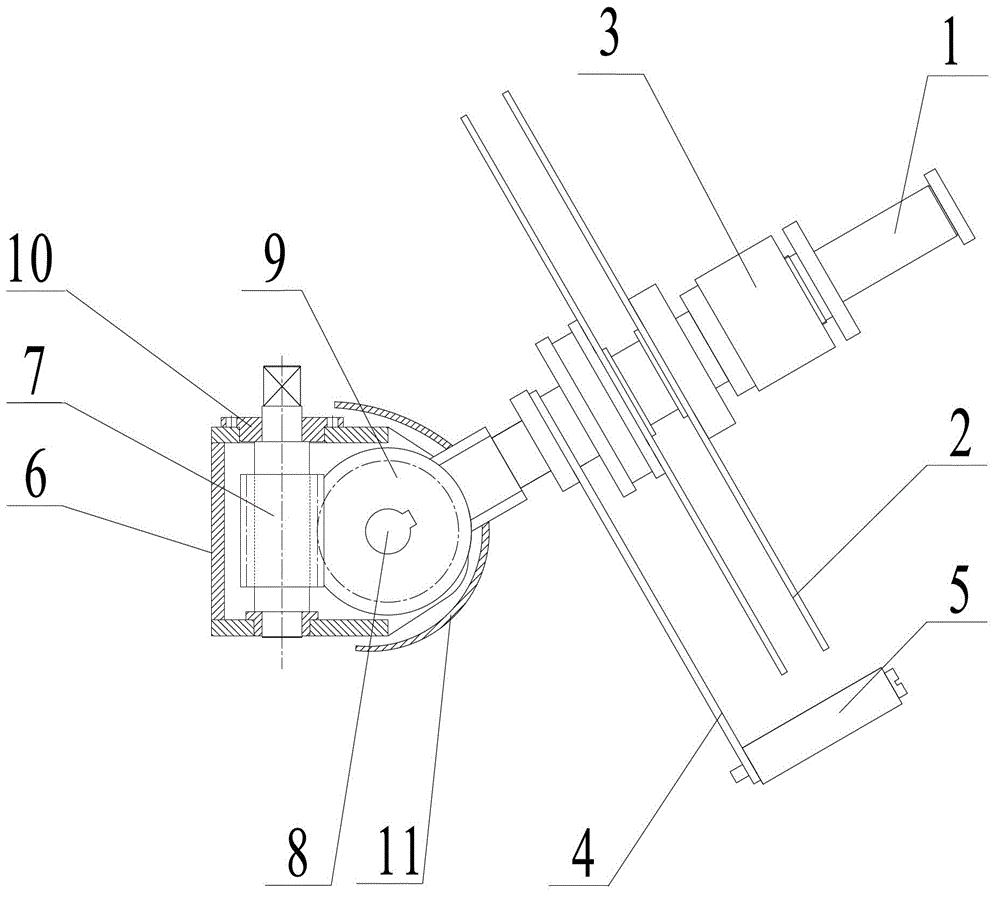

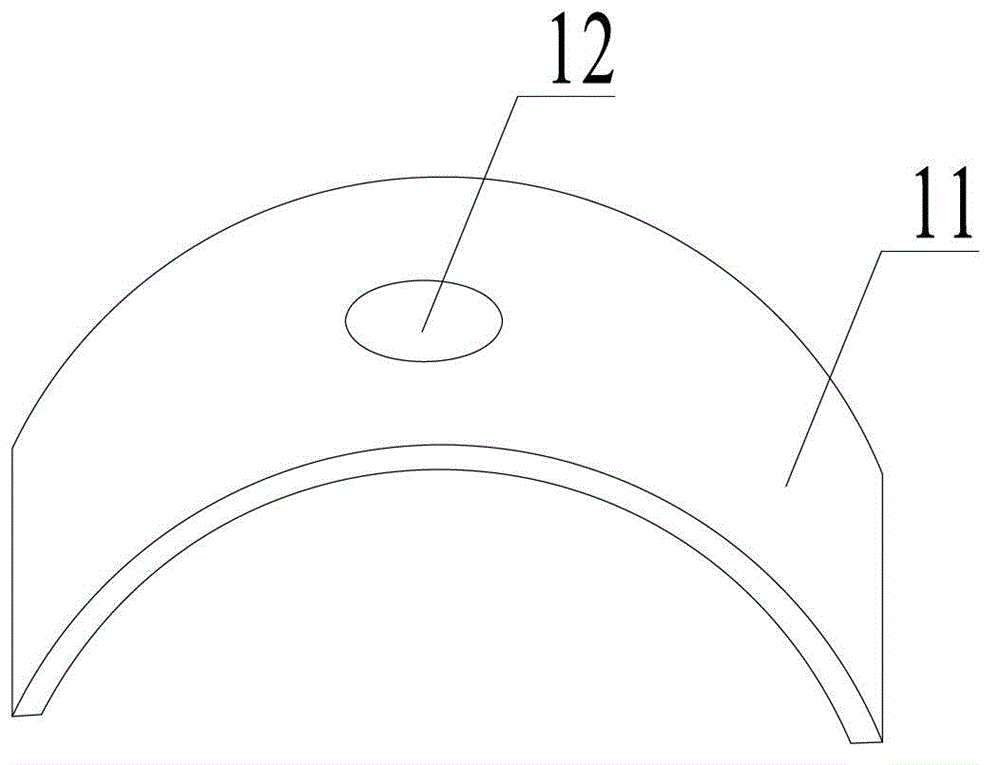

[0015] refer to figure 1 , including a reel shaft 1, a tape reel device 2 installed in the middle of the reel shaft 1, a locking device 3 sleeved on the upper half of the reel shaft 1 and used to lock the tape reel device 2, and one end is fixedly connected to the reel The guide roller frame 4 on the lower half of the mandrel 1 and the guide roller 5 connected to the other end of the guide roller frame 4 are characterized in that the bottom end of the disc mandrel 1 is fixedly connected with a worm gear device, and the worm gear The device is installed in the worm gear box 6; the worm gear device includes a worm 7 installed on the worm gear box 6, a worm gear shaft 8 installed on the worm gear box 6, a worm gear 9 mounted on the worm gear shaft 8 and meshed with the worm screw 7, The axes of the worm 7 and the worm wheel 9 are perpendicular to each other, and the bottom end of the disk mandrel 1 is fixedly connected to the worm shaft 8; one end of the worm 7 stretches out from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com