Method and device for quickly repairing convertor tap hole

A technology for tapping holes and converters, which is applied in the field of rapid repair of tapping holes for converters, which can solve the problems of increased consumption of refractory materials, short life of the tapping hole, and affecting the life of the tapping hole, so as to reduce the consumption of refractory materials and reduce production cost, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with the accompanying drawings, the specific embodiments of the present invention are described in one step:

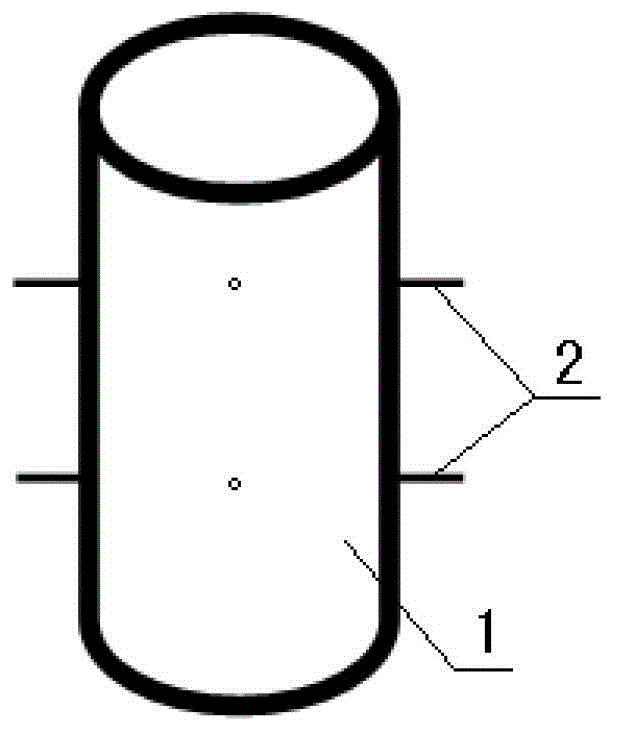

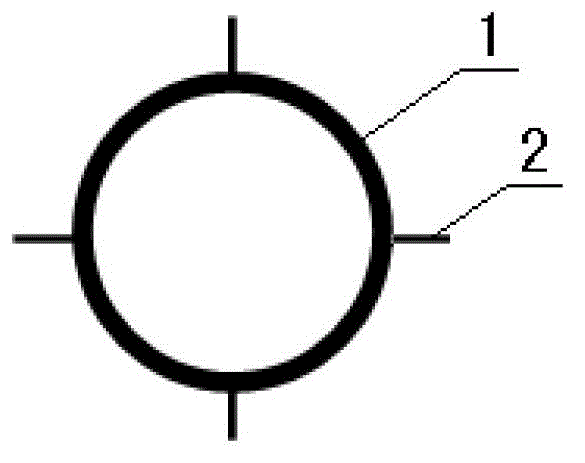

[0012] See figure 1 , figure 2 , is the structural schematic diagram of the embodiment of the steel cylinder of the present invention, its diameter is the same as the diameter of the tapping hole, its length is 1.05~1.15 times that of the tapping port, and the outer circumference of the cylinder body 1 is uniformly welded with several steel columns 2, and the steel columns 2 The diameter is 3~5mm, and the diameter of the steel cylinder plus the length of the two steel columns is not greater than the diameter of the tap hole after reaming. The cylinder body 1 is welded by seamless steel pipes or iron plates. The steel columns 2 are evenly arranged, so as to ensure that the thickness of the repair material between the cylinder 1 and the tap hole is the same when repairing, so as to prevent the center line of the tap hole after the repair f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com