A magnetic levitation support for a refrigeration compressor

A refrigeration compressor and magnetic levitation technology, applied in the field of refrigeration compressors, can solve problems such as the inability to achieve shock absorption effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

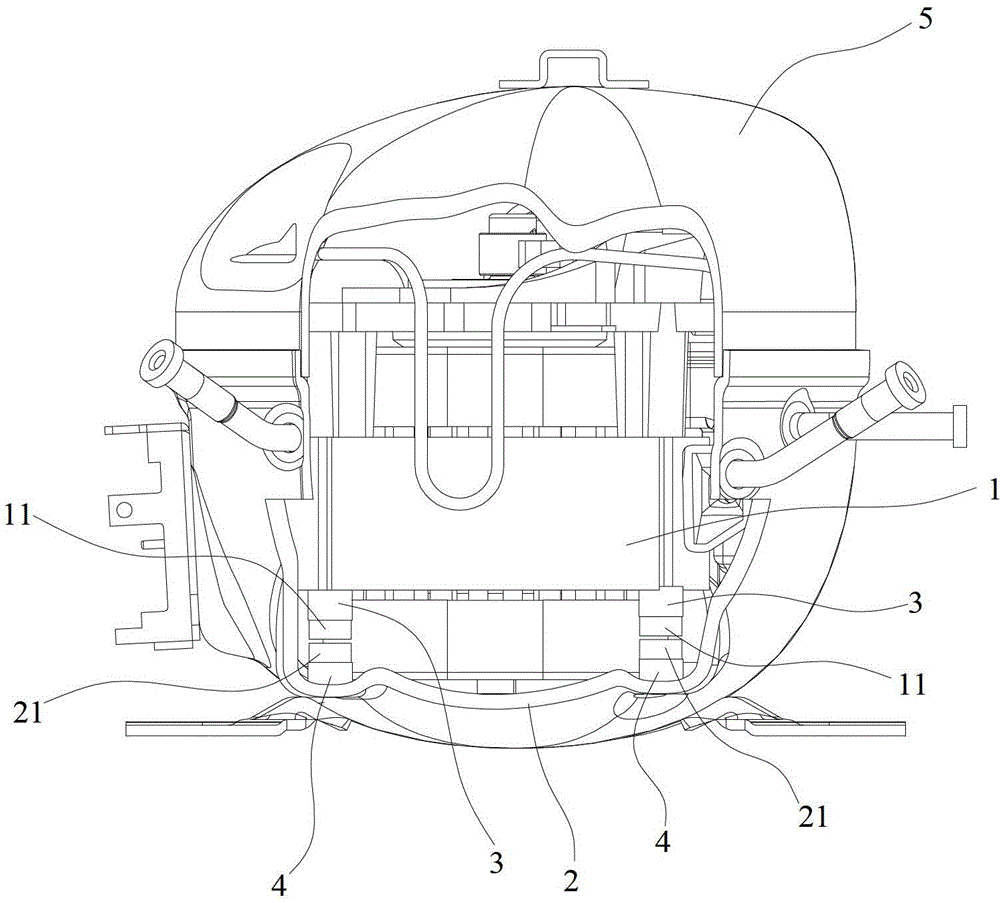

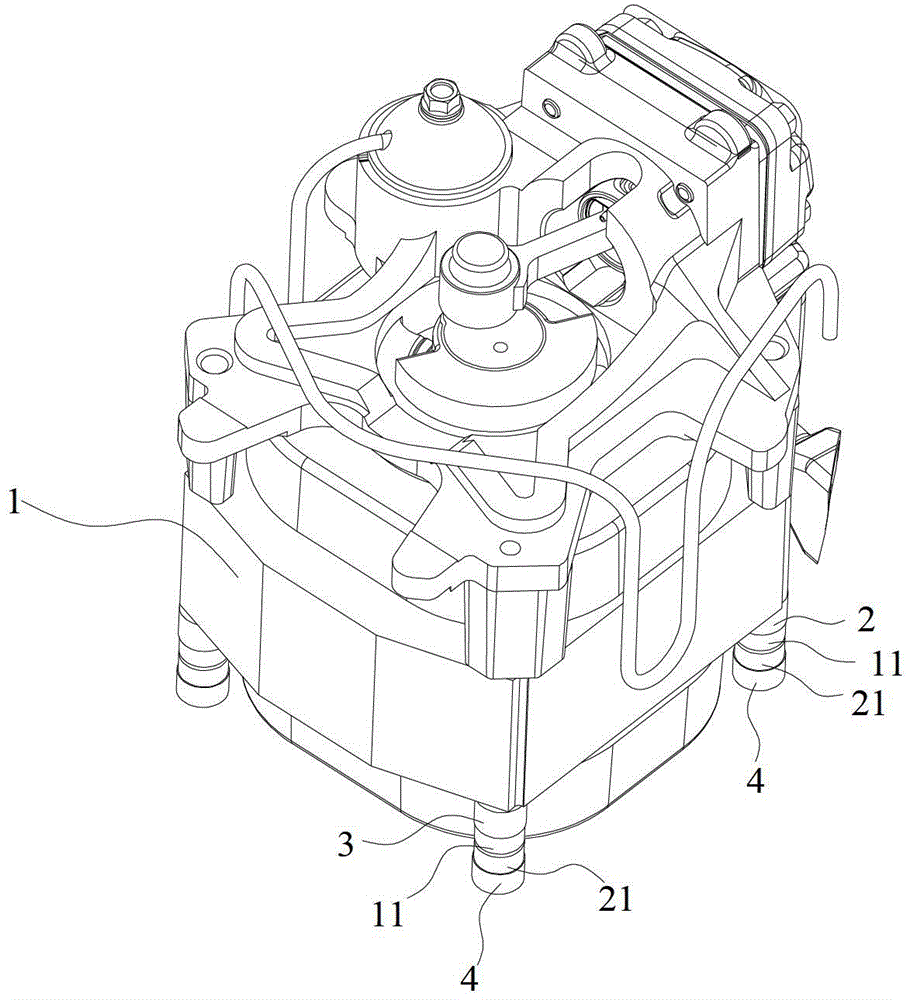

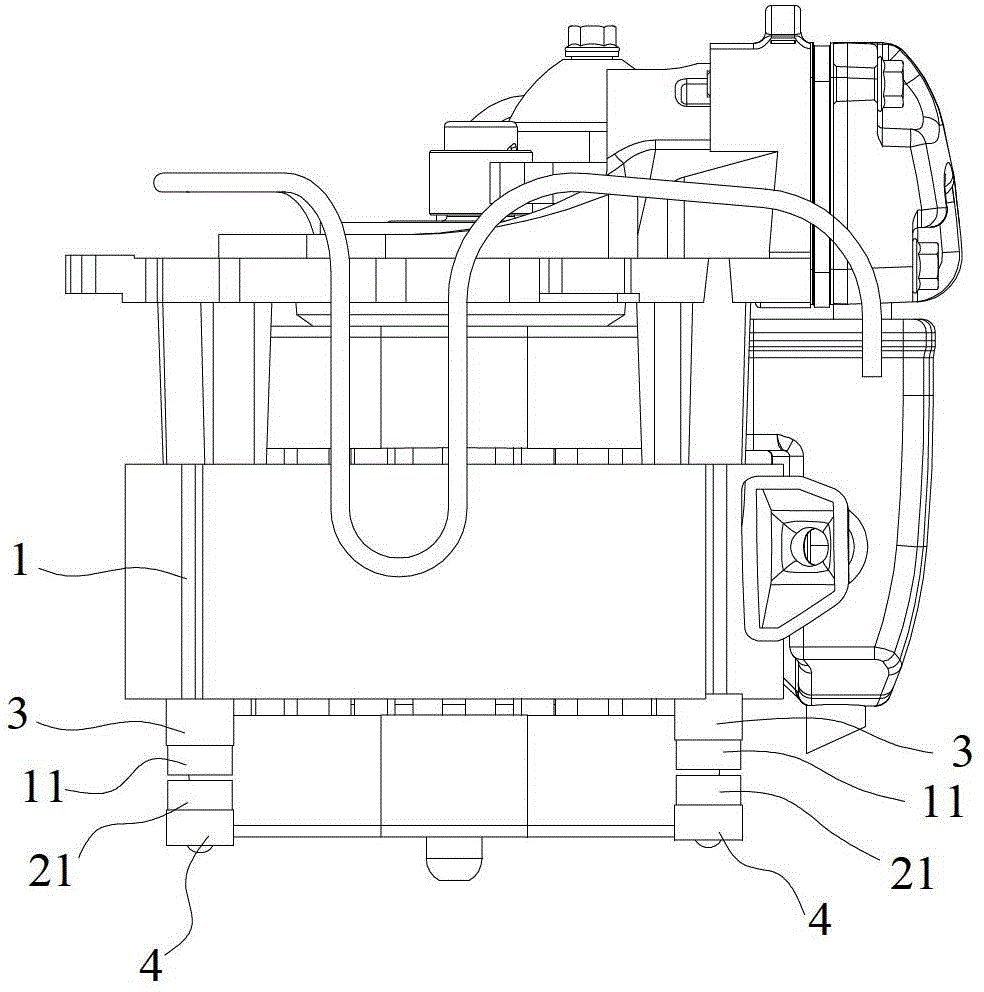

[0018] refer to Figure 1 to Figure 5 , the present invention provides a magnetic levitation support for a refrigeration compressor, which includes an upper magnet 11 arranged on the lower side of the core 1 and a lower magnet 21 arranged on the inner side of the lower shell 2, the upper magnet 11 and the lower magnet 21 are arranged facing each other with the same pole, The movement 1 is suspended above the lower case 2 .

[0019] The magnetic levitation support of this refrigeration compressor suspends the core 1 above the lower shell 2 through the mutual repulsion between the same poles of the upper magnet 11 and the lower magnet 21, so that the core 1 and the lower shell 2 are completely separated, and the gap between the core 1 and the shell There is no direct or indirect contact through the compression spring, that is, the transmission path of the vibration is completely blocked, so that the vibration of the movement 1 cannot be transmitted to the outside of the refriger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com