Reinforcing welded steel ball seat

A technology of reinforcement welding and steel ball seat, applied in the direction of building components, etc., can solve the problems of affecting the sealing, the steel ball is easy to fall off, and the difficulty is high, and achieves the effects of improved stability, easy welding, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

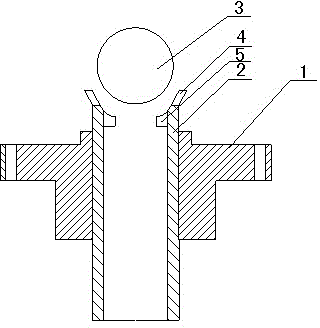

[0011] Such as figure 1 As shown, the steel ball seat reinforced and welded according to the embodiment of the present invention includes a spring seat 1 and a cotter pin 2. A through hole penetrating up and down is provided at the center of the spring seat 1, and a cotter pin 2 is inserted into the through hole. And the cotter pin 2 is gradually embedded along the inner wall surface of the spring seat 1 from bottom to top, and a steel ball 3 is arranged at the opening end of the cotter pin 2;

[0012] At the same time, a circle of outwardly inclined arc top welding strip 4 is arranged on the top of the cotter pin 2 and the inner wall surface of the arc top welding strip 4 is an arc structure, and a circle of welding boss 5 is arranged on the inner wall surface of the opening of the cotter pin 2 And the upper surface of the welding boss 5 is arc-shaped.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap