Taper position gauge for accurately measuring big end diameter error of taper hole

A precise measurement and gauge technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of inconvenient measurement and inaccurate distance, and achieve the effect of avoiding excessive wear of the end face, improving accuracy and strong replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, the present invention is described in further detail:

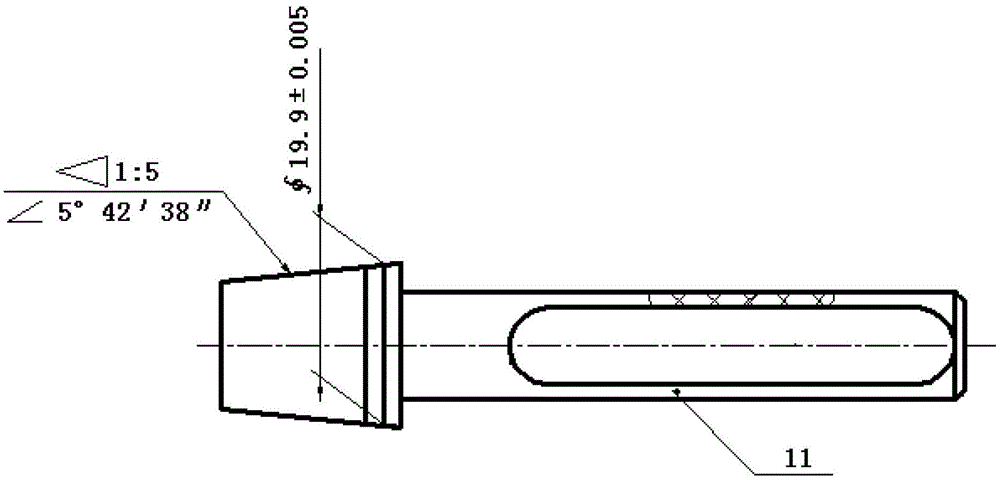

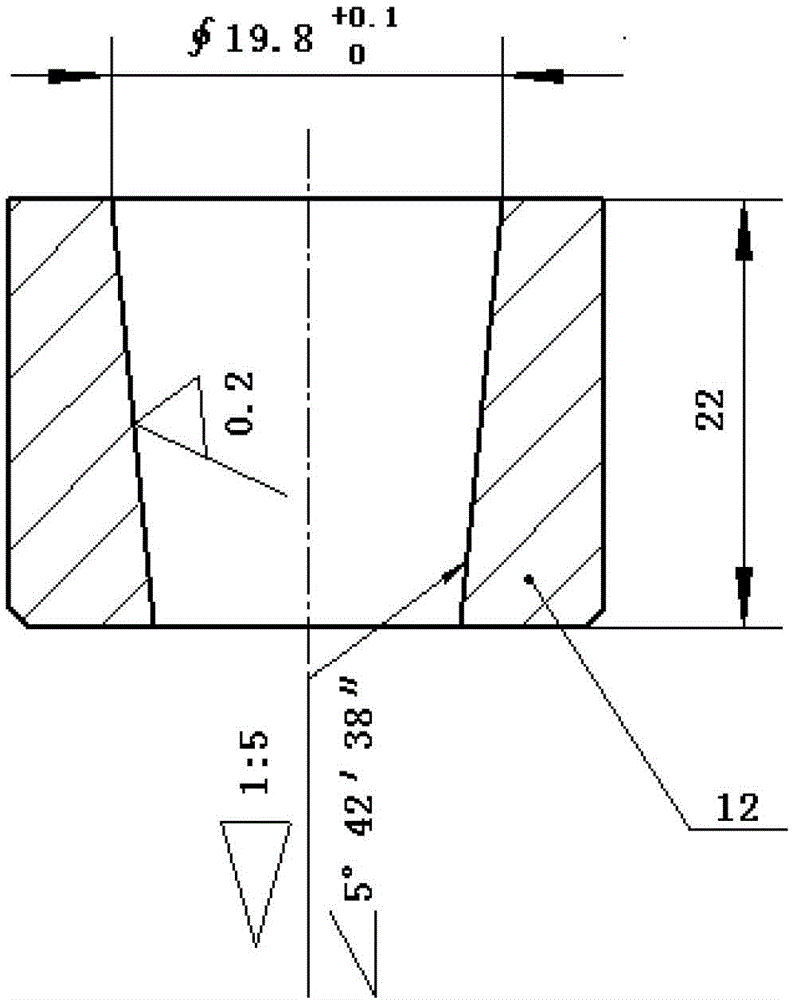

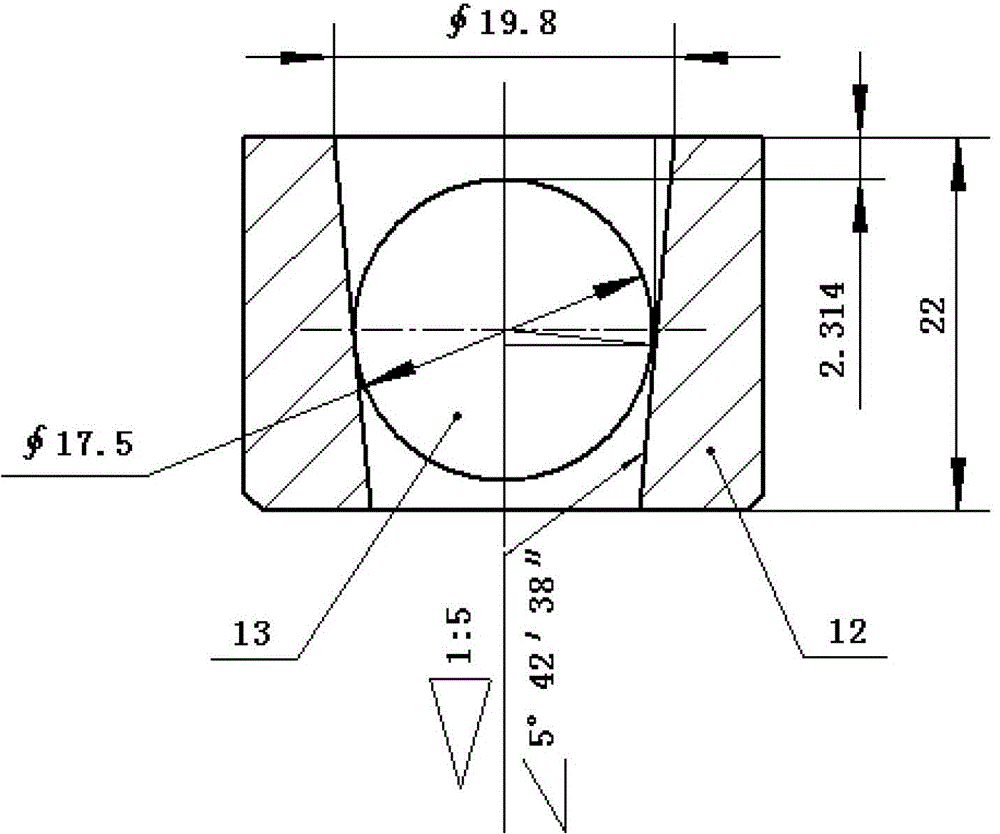

[0040] A taper gauge for accurately measuring the diameter error of the large end of a taper hole, such as Figure 4 As shown, it includes a pair of watch parts 1, a measuring rod 3, a gauge lower body 2, a gauge upper body 5, a spring 4, a fastening screw 6, a bushing 7, and a dial gauge 8. The measuring rod 3 is movably installed inside the lower body 2 of the gauge, and the lower part of the measuring rod 3 is equipped with a measuring head 31 matched with the tapered hole to be measured. The upper part of the gauge lower body 2 is connected to the gauge upper body 5, and the inside of the gauge upper body 5 is equipped with a dial gauge 8, and the top of the measuring rod 3 contacts with the contact of the dial gauge 8. A spring 4 is installed inside the upper body 5 of the gauge, and the spring 4 is mainly used to provide elastic force for the measuring rod 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com