Battery case for electric vehicle and manufacturing method thereof

A technology for electric vehicles and manufacturing methods, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of complex processing technology, long production cycle, inconvenient manufacturing, etc., to simplify the process flow, improve the integrity, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

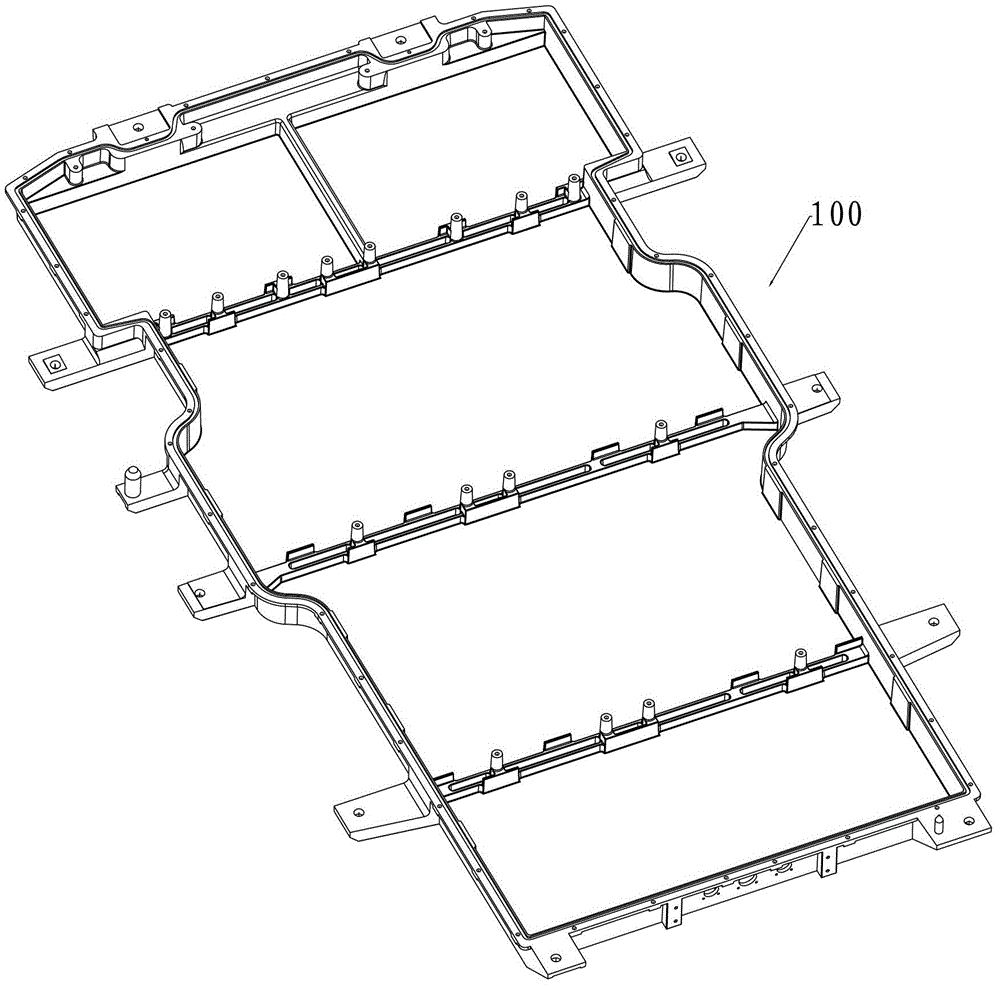

[0019] see figure 1 , the present embodiment is a battery box 100 of an electric vehicle, the battery box 100 is an integral molding, and its manufacturing method includes the following steps:

[0020] Cast aluminum 102 is used as the casting material, and the blank of the battery box 100 is formed by gravity casting. The wall thickness of the blank is at least 6 mm, and a machining allowance is left; the blank of the battery box 100 is clamped on a CNC machine tool In this process, all mounting surfaces are processed, drilled and tapped in one clamping; the shape of the battery case 100 is corrected; and the surface of the battery case 100 is treated and painted by electrophoresis processing.

[0021] When manufacturing the battery box o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com