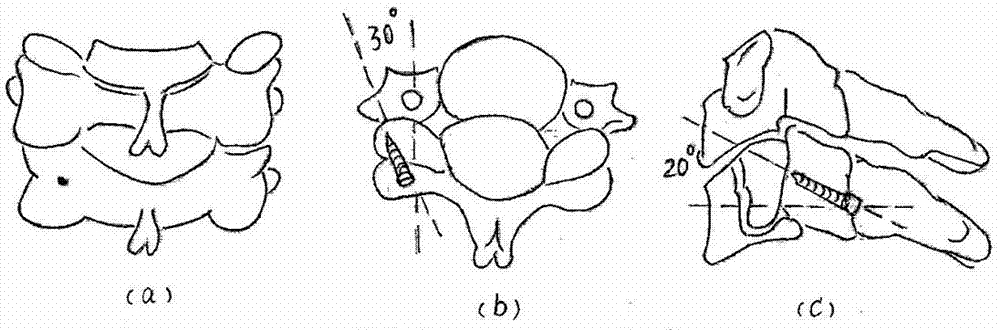

Cervical posterior lateral mass screw fixation guide and screw fixation method

A technology of screw fixation and guide, which is applied in the fields of fixers, fastening devices, medical science, etc., can solve the problem that the screw screwing direction cannot be accurately controlled, and achieve the effect of reducing surgical risk, simple positioning method, and firm screw fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

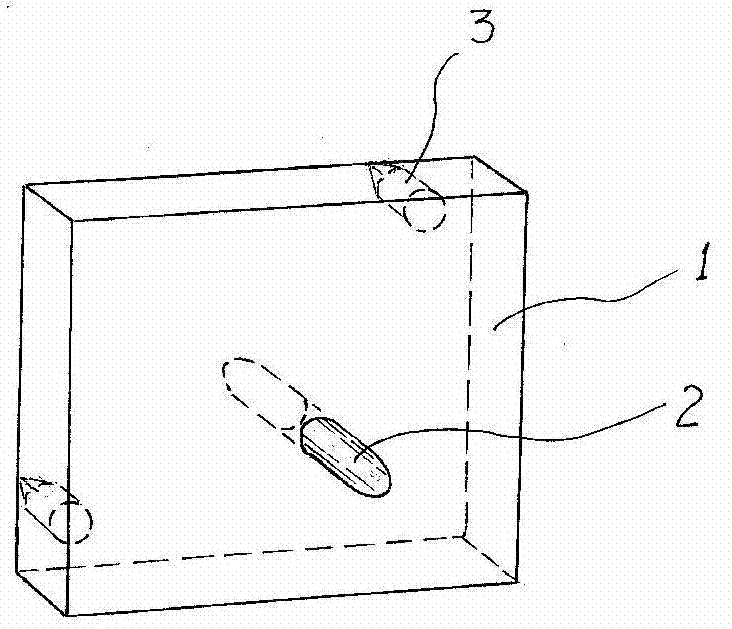

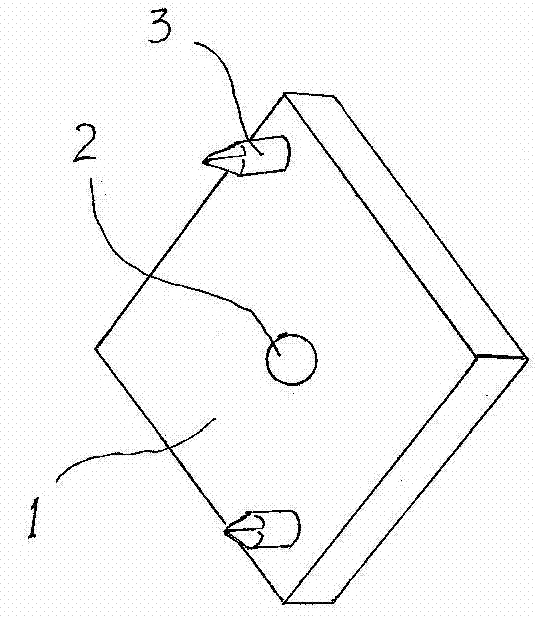

[0020] Embodiment 1: The screw fixation guide for the posterior lateral mass of the cervical spine of the present invention includes a left guide and a right guide, and the left guide and the right guide have left-right symmetrical structures.

[0021] figure 2 , image 3 It is a schematic diagram of the structure of the front and back of the left guide. The specific structure is to make a square positioning plate 1 with a side length of 1.18-1.22cm and a thickness of 1.48-1.52mm. To the through hole 2 passing through the board surface, the diameter of the through hole is 1.0-1.3mm, and the direction of the through hole is to pass through the board surface obliquely from the direction of the lower right corner of the front of the positioning board 1 to the direction of the upper left corner of the back, and the direction of the through hole is The included angle between the axis line and the projection line of the axis line on the positioning plate 1 is 20°. The center poin...

Embodiment 2

[0022] Embodiment 2: The screw fixation method of the cervical posterior lateral mass of the present invention comprises the following steps:

[0023] a. Align the left side and the bottom edge of the positioning plate 1 of the left guide with the nearly right-angled protruding edge on the left lateral mass of the posterior cervical spine, so that the positioning plate 1 basically covers the left lateral mass of the posterior cervical spine top surface.

[0024] b. Hammer the surface of the positioning plate 1 of the left guide, and nail the positioning nail 3 on the positioning plate 1 into the bone of the posterior lateral mass of the cervical spine.

[0025] c. Insert a drill bit with a diameter of 0.8-0.9 mm into the through hole 2 on the left guide positioning plate 1, and drill in the bone of the posterior cervical vertebra along the axis of the through hole 2 Hole operation, the drilling depth does not exceed 3mm.

[0026] d. Repeat steps a-c, and use the right guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com