Suspending ultrafine dry powder self-service extinguishing device

A technology of ultra-fine dry powder and fire extinguishing device, which is applied in fire rescue and other fields, can solve the problems of secondary disasters caused by gunpowder and excessive dry powder deposition, and achieve strong eruption, uniform dispersion, and improved spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

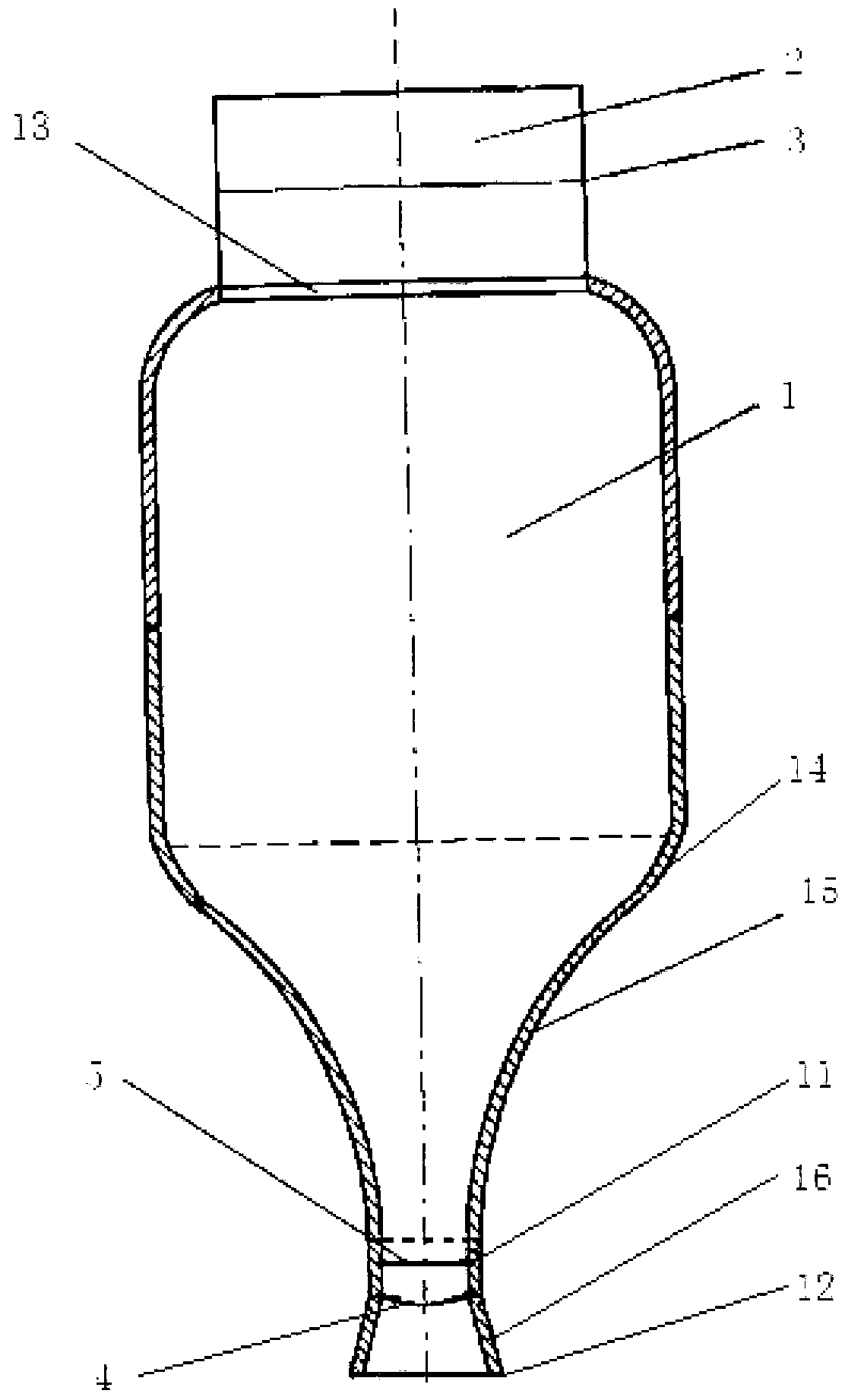

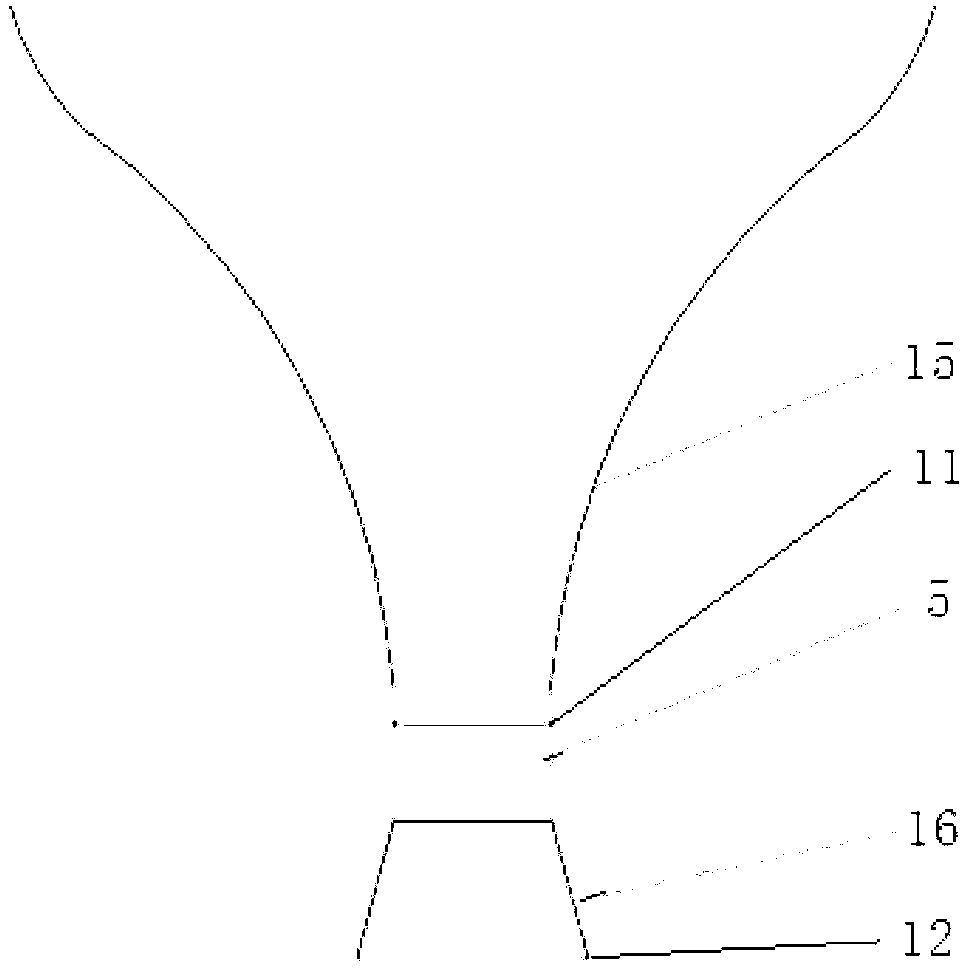

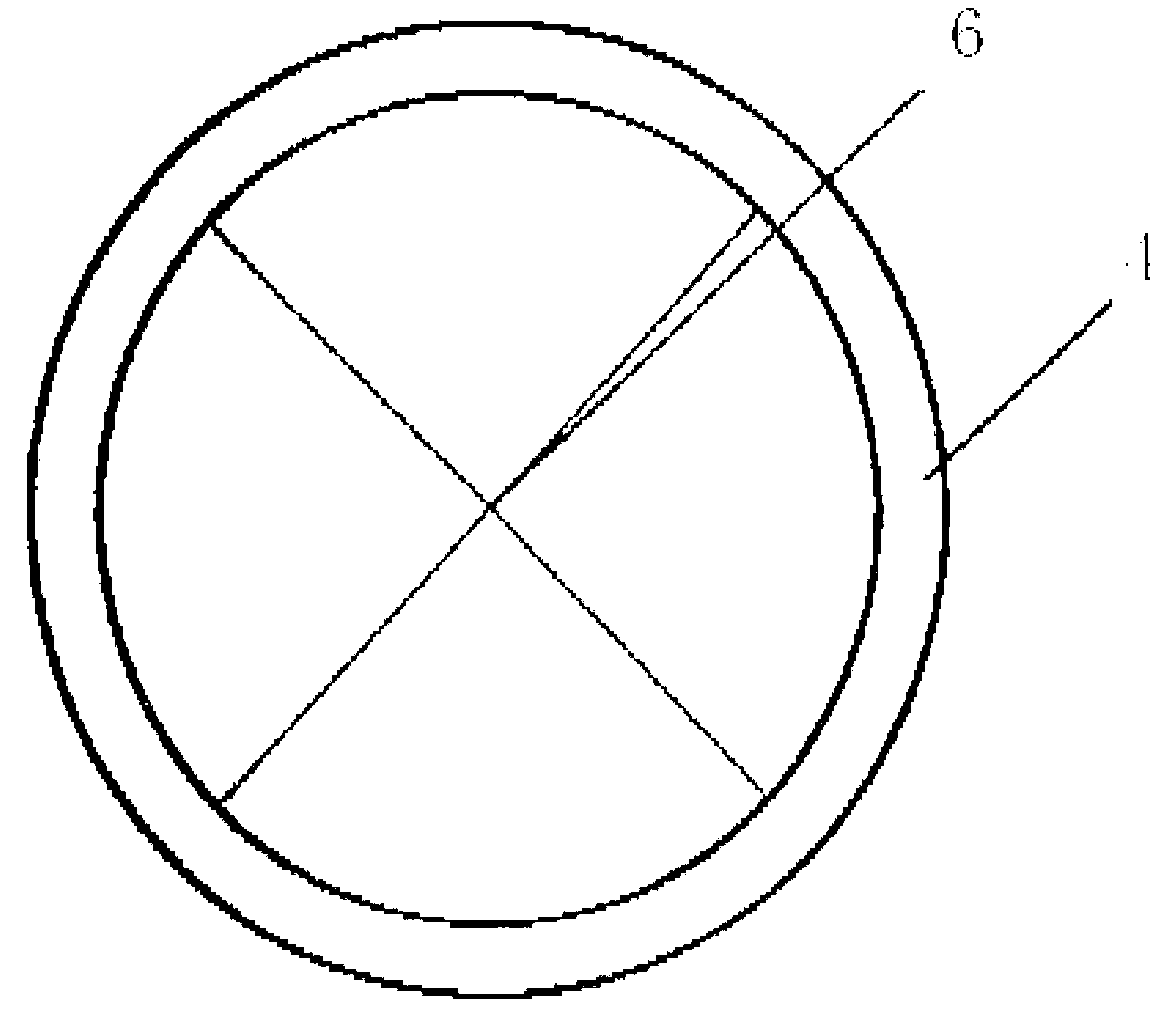

[0028] like figure 1 As shown, the suspended ultrafine dry powder self-service fire extinguishing device of the present invention mainly includes a bottle body 1 and a gas generator 2 . The bottle body 1 is in the shape of a vase, and its two ends are divided into an open end 11 and a blind end 13. The blind end 13 is located at the bottom of the bottle body 1, and the mouth of the bottle body 1 has a gradually narrowing converging section 15 similar to an inverted cone. , the end of the converging section 15 forms the open end 11 of the bottle body 1 . The opening end 11 gradually expands to form an expansion section 16 similar to a positive cone, and the end of the expansion section 16 forms an injection port 12 . The narrow opening of the extension section 16 is connected to the opening end 11, and a prefabricated diaphragm 4 is fixed between the narrow opening of the extension section 16 and the opening end 11, for blocking the ultrafine dry powder fire extinguishing agen...

Embodiment 2

[0033] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that a deflector plate 9 for diverting ultrafine dry powder fire extinguishing agent is erected outside the injection port 12 through a bracket 8 . Since the ultra-fine dry powder fire extinguishing agent is a solid particle, after high-speed injection, some ultra-fine dry powder fire extinguishing agent particles collide, part of the momentum is lost, and they fall vertically under the action of gravity and high-pressure gas thrust, and it is easy to form a deposition area at the injection port 12. Make superfine dry powder fire extinguishing agent can't be effectively utilized. In the present invention, a cylindrical shroud 7 is arranged on the outside of the converging section 15 and the expanding section 16 , and a fixed surface 10 is horizontally arranged on the port of the shroud 7 near the injection port 12 . The fixed surface 10 is an annular plane, and the end of the extension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com