Cleaning method of glass substrate and device for implementing method

一种玻璃基板、清洗装置的技术,应用在清洗领域,能够解决重量大、杂质702无法被吸附、影响液晶显示面板显示效果等问题,达到克服去除能力差、提升品质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

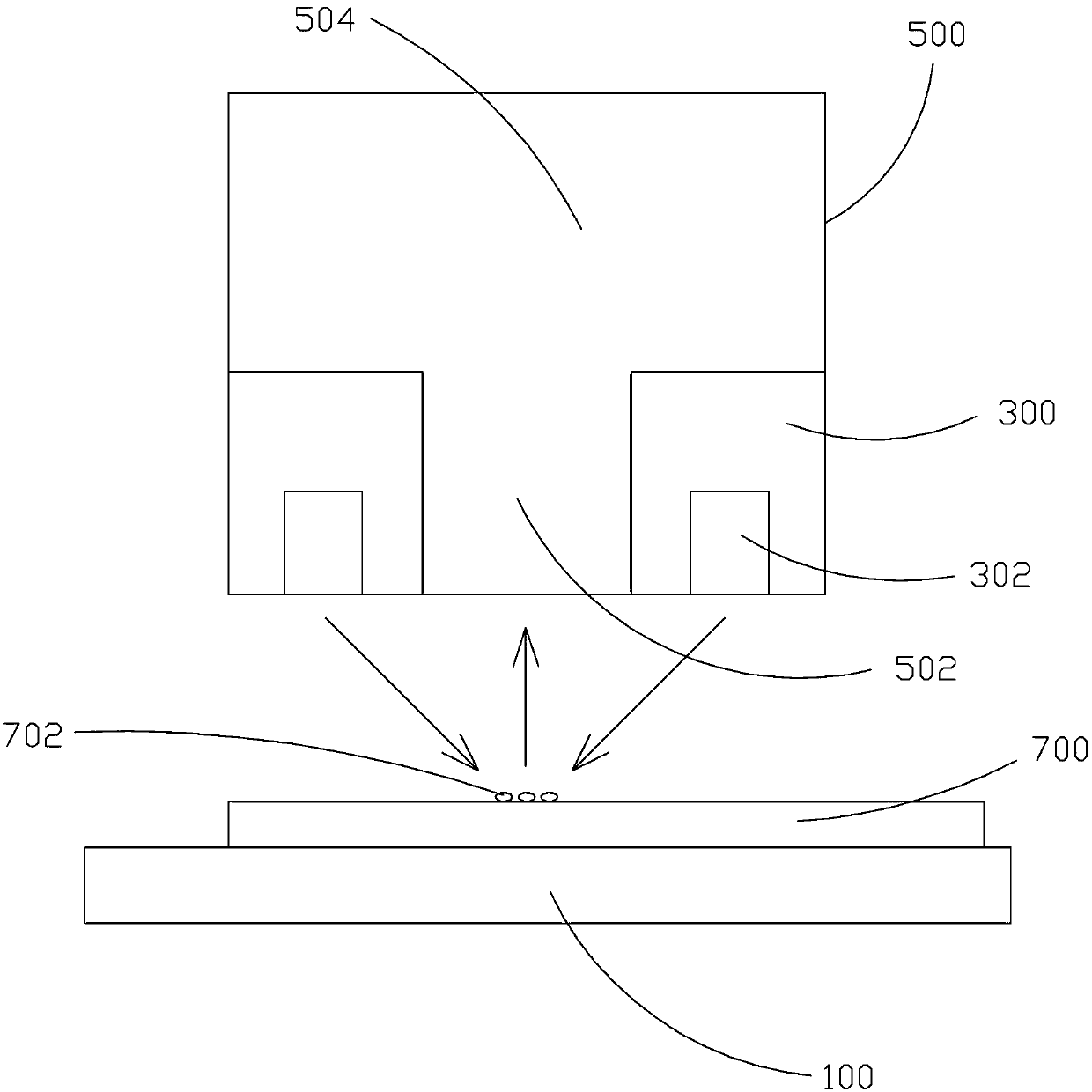

[0032] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

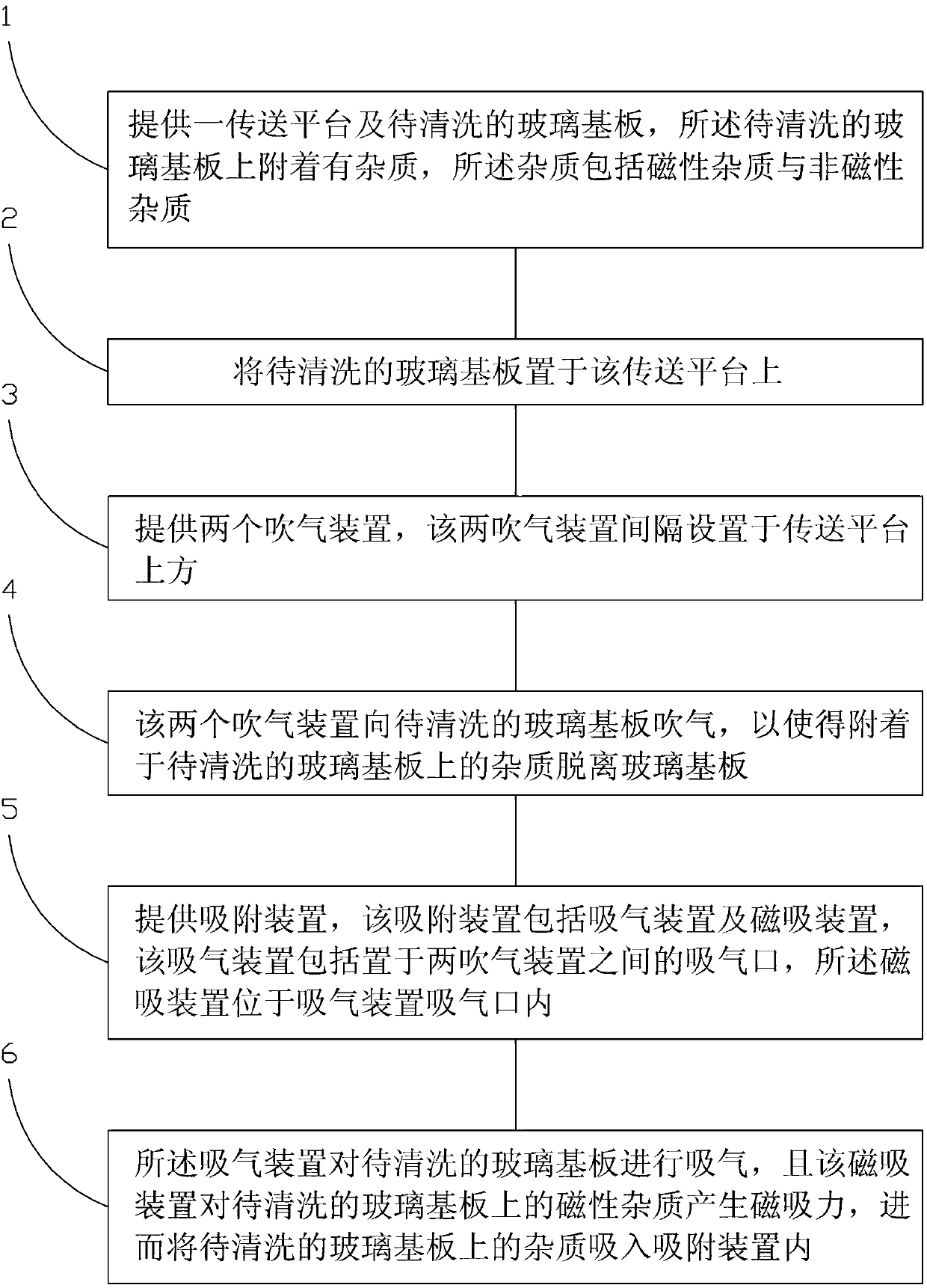

[0033] see image 3 and Figure 4 , the invention provides a cleaning method for a glass substrate, comprising the following steps:

[0034] Step 1. Provide a transfer platform 20 and a glass substrate 40 to be cleaned. Impurities 42 are attached to the glass substrate 40 to be cleaned. The impurities 42 include magnetic impurities and non-magnetic impurities.

[0035] Step 2, placing the glass substrate 40 to be cleaned on the transfer platform 20 .

[0036] Step 3, providing two air blowing devices 60 , the two air blowing devices 60 are arranged above the conveying platform 20 at intervals.

[0037] Preferably, each blowing device 60 is provided with an ultrasonic generator.

[0038] Step 4, the two air blowing devices 60 blow air to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com