Intermittent transfer coating head and its transfer coating machine capable of precisely positioning the coating length

A precise positioning, intermittent technology, applied in the direction of the surface coating device, coating, etc., can solve the problems of cutting off the normal coating, inaccurate length of the coating interval, and unstable base tape. , to achieve the effect of overcoming slippage and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

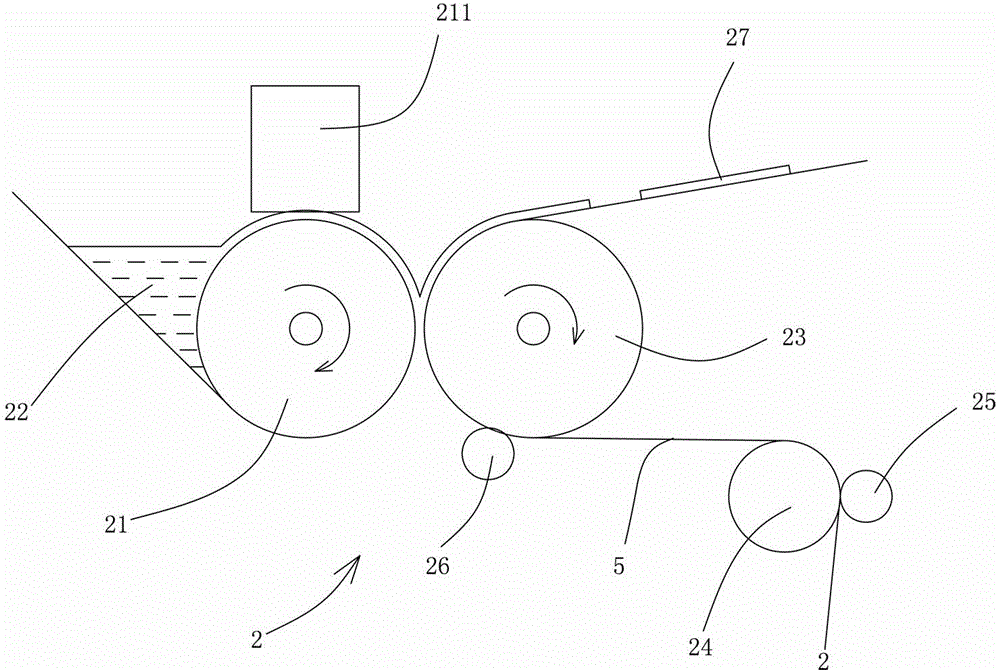

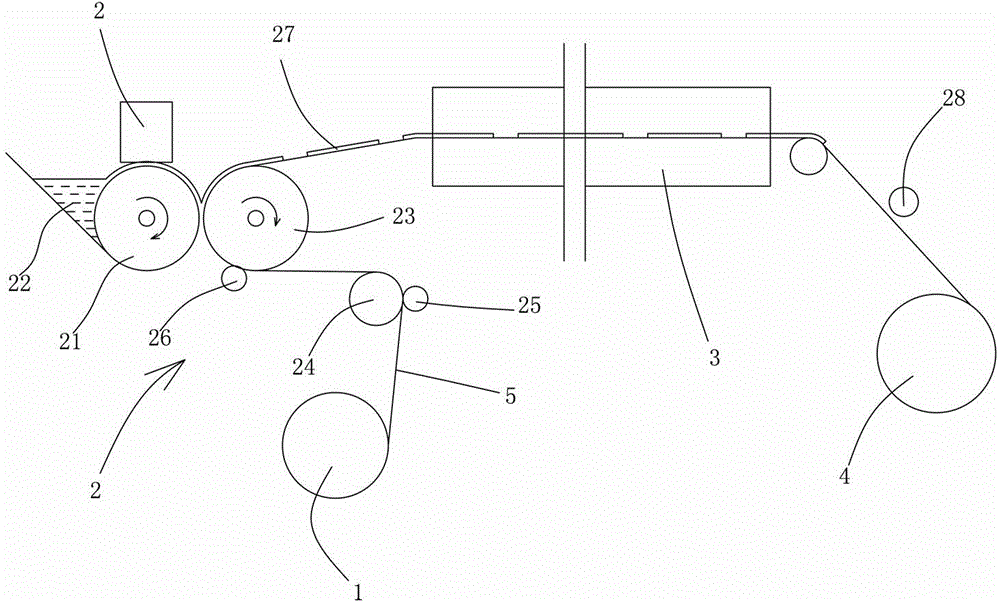

[0019] See figure 1 , figure 1 Disclosed is an intermittent transfer coating head that can precisely position the coating length, and the intermittent transfer coating head 2 includes a controller, a driving roller 21 with a knife edge 211, and a device for supplying slurry to the driving roller 21 Hopper 22, cooperating with driving roll 21 to transfer slurry 27 to the back roll 23 on the base material 5, and the transition roll 24 used to convey the base material before the back roll 23, the back roll 23 is driven by the first driving device Drive, the present invention is also provided with a second drive device, the second drive device drives the transition roller 24 to rotate, and the first drive device and the second drive device are electrically connected to the controller. In the present invention, according to the slipping state of the substrate (that is, the substrate does not move or moves at an excessive speed relative to the back roller), the slipping detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com