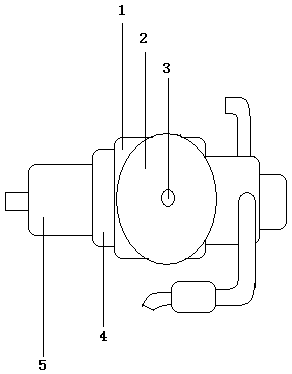

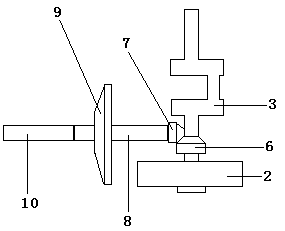

Power turning output device for internal combustion engine

A technology of power changing and output devices, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve problems such as increased use cost, slippage, and large power consumption, and achieve the effect of small use space and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] During the use of an internal combustion engine power change output device, the flywheel of the diesel engine is started to reach the rated speed, and the driving bevel gear installed on the crankshaft transmits the power of the flywheel to the driven bevel gear, and the driven bevel gear transmits the power to the driven bevel gear. The power output shaft, the power output shaft transmits power to the main shaft of the gearbox through the clutch friction plate assembly, and then transmits the power to the drive axle of agricultural machinery after speed change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com