An inspection car that can be turned over automatically

A technology for automatically flipping and inspecting vehicles, applied in the field of inspection vehicles, can solve the problems of increased track costs and inspection vehicle costs, complex structure of bridge-type inspection vehicles, low inspection efficiency, etc., to reduce delays, reduce mechanical failure rates, and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

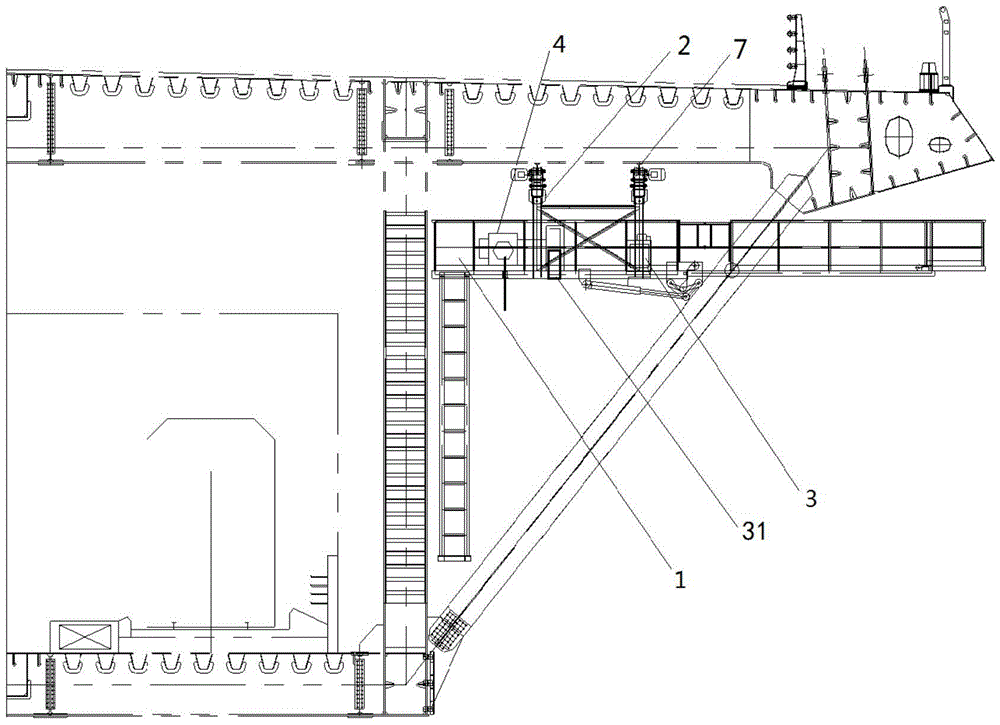

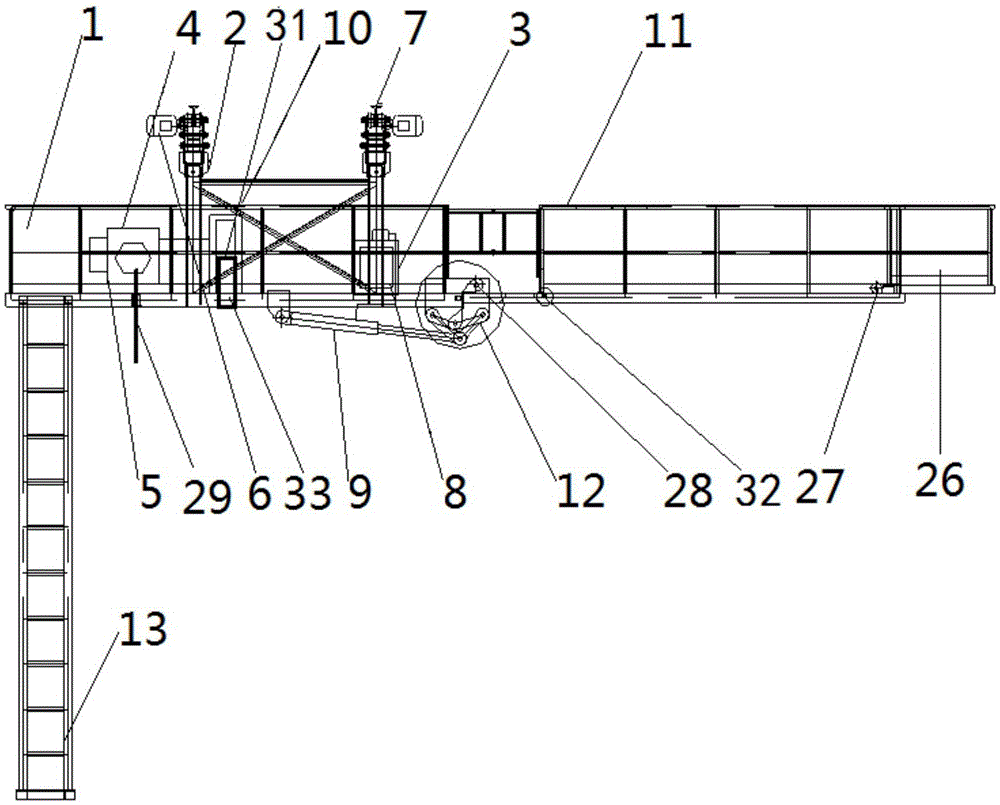

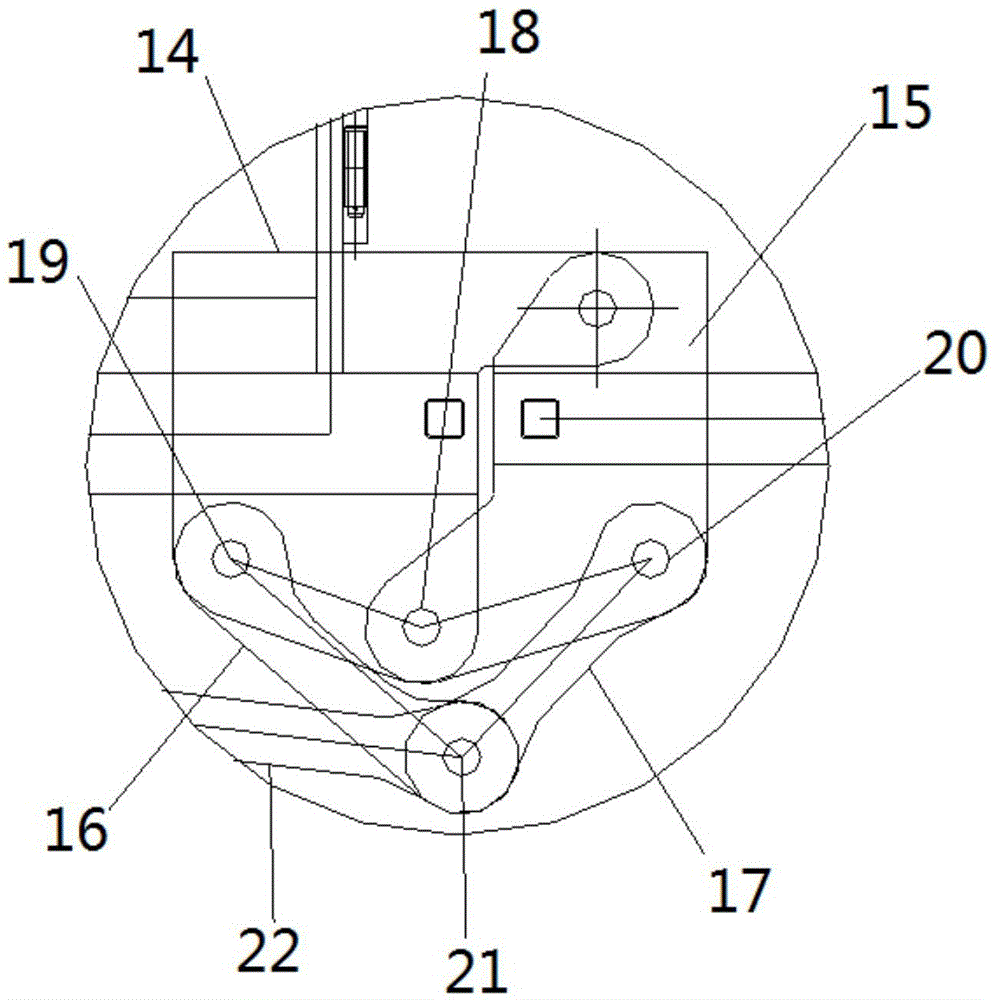

Image

Examples

Embodiment 1

[0099] As the inspection vehicle described above, the present embodiment differs from it in that, as Figure 7 As shown, it is a structural schematic diagram of Embodiment 1 of the automatic overturning inspection vehicle of the present invention, wherein the profiling system 2 of the inspection vehicle also includes an acceleration controller 38, and the acceleration controller 38 is connected with the profiling track 7, and it is connected with the profiling track 7. Shaped track 7 works together to apply constant resistance to the inspection car in motion, so as to control the inspection car to perform deceleration motion with constant acceleration, that is, uniform deceleration motion;

[0100] In this embodiment, the controller 33 can also calculate the acceleration required when the inspection vehicle is braked to a stop, and transmit the calculated acceleration to the acceleration controller 38;

[0101] After the acceleration controller 38 receives the acceleration, it...

Embodiment 2

[0109] As the inspection vehicle described in the above-mentioned embodiment, the difference of this embodiment is that, as Figure 8 As mentioned above, it is a structural schematic diagram of the second embodiment of the automatic overturning inspection vehicle of the present invention, wherein the inspection vehicle also includes an alarm 39, and the alarm 39 sends out an alarm after receiving the alarm signal from the controller 33 to remind the inspection vehicle The workers on the board quickly patented from the inspection car;

[0110] The controller 33 will send an alarm signal to the alarm 39 only after determining the final distance of the inspection vehicle and the final distance is less than the standard collision distance.

Embodiment 3

[0112] As the inspection vehicle described in the above-mentioned embodiment, the difference of this embodiment is that, as Figure 9 As mentioned above, it is a structural schematic diagram of the third embodiment of the automatic reversible inspection vehicle of the present invention, wherein a switch 40 is directly connected between the controller 33 and the connecting line of the device controlled by the controller 33, and the controller 33 can be cut off by disconnecting the switch 40. Controls of the inspection cart to manually control the movement and rollover of the inspection cart. This can prevent the inspection vehicle from being unable to use normally after the controller 33 or the control subsystem 31 breaks down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com