High-durability and long-scale-distance fiber grating sensor and manufacturing method therefor

a fiber grating sensor, long-scale technology, applied in the direction of cladded optical fibre, optical apparatus testing, instruments, etc., can solve the problems of poor durability of conventional sensors, unsuitable for long-term real-time monitoring in embedded state, and subject to severe interference, etc., to achieve poor stability and durability, high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The technical scheme of this disclosure will be further detailed hereinafter, with reference to the accompanying drawings.

[0047]According to the function and measuring accuracy, the LG-FBG sensors with high durability and long gauge length can be classified into three types: basic type, filled type and sensitizing enhanced type.

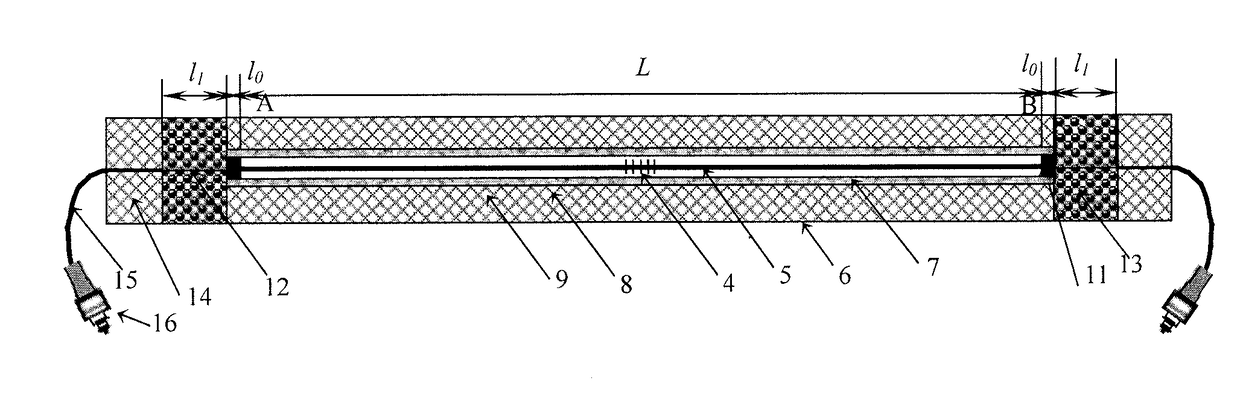

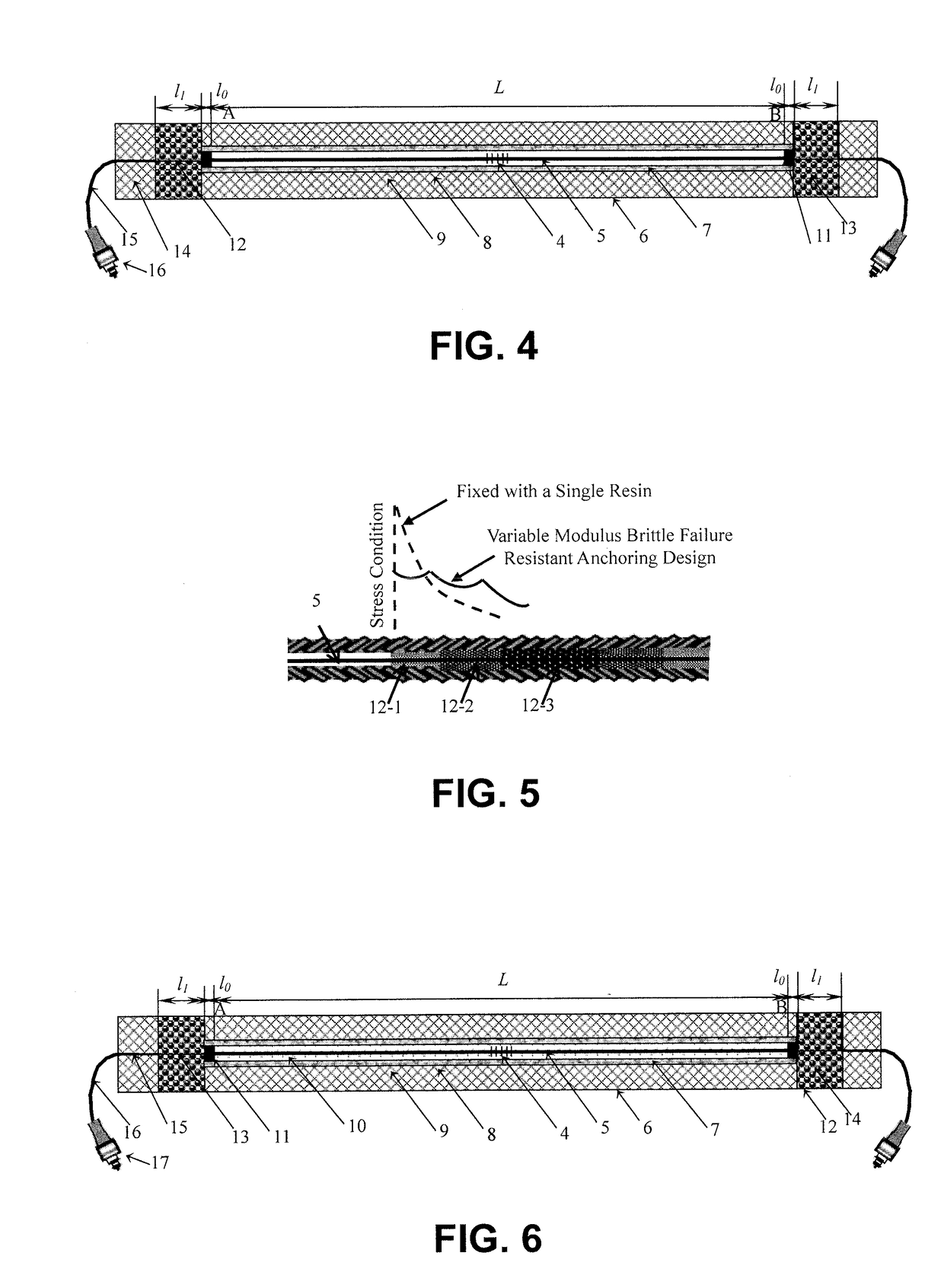

[0048]1) As shown in FIG. 4, a basic type of LG-FBG sensor comprises a commercial optical fiber 5 in length L, the coating layer of the commercial optical fiber can be penetrated by 248 nm excimer laser, and optical fiber Bragg grating can be inscribed without stripping off the coating layer; a fiber Bragg grating 4 is arranged on the middle segment of the commercial optical fiber 5, a bushing 7 is arranged on the periphery of the commercial optical fiber 5, a specially designed basalt woven reinforced fiber jacket layer 8 and a packaging structure 6 are arranged on the periphery of the commercial optical fiber 5, and the commercial optical fiber 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com