Stamping die used for metal pipe mouth forming

A technology for stamping dies and metal pipes, which is applied in the field of dies for mechanical processing, and can solve the problems of high die manufacturing costs and expensive equipment for nozzle forming machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

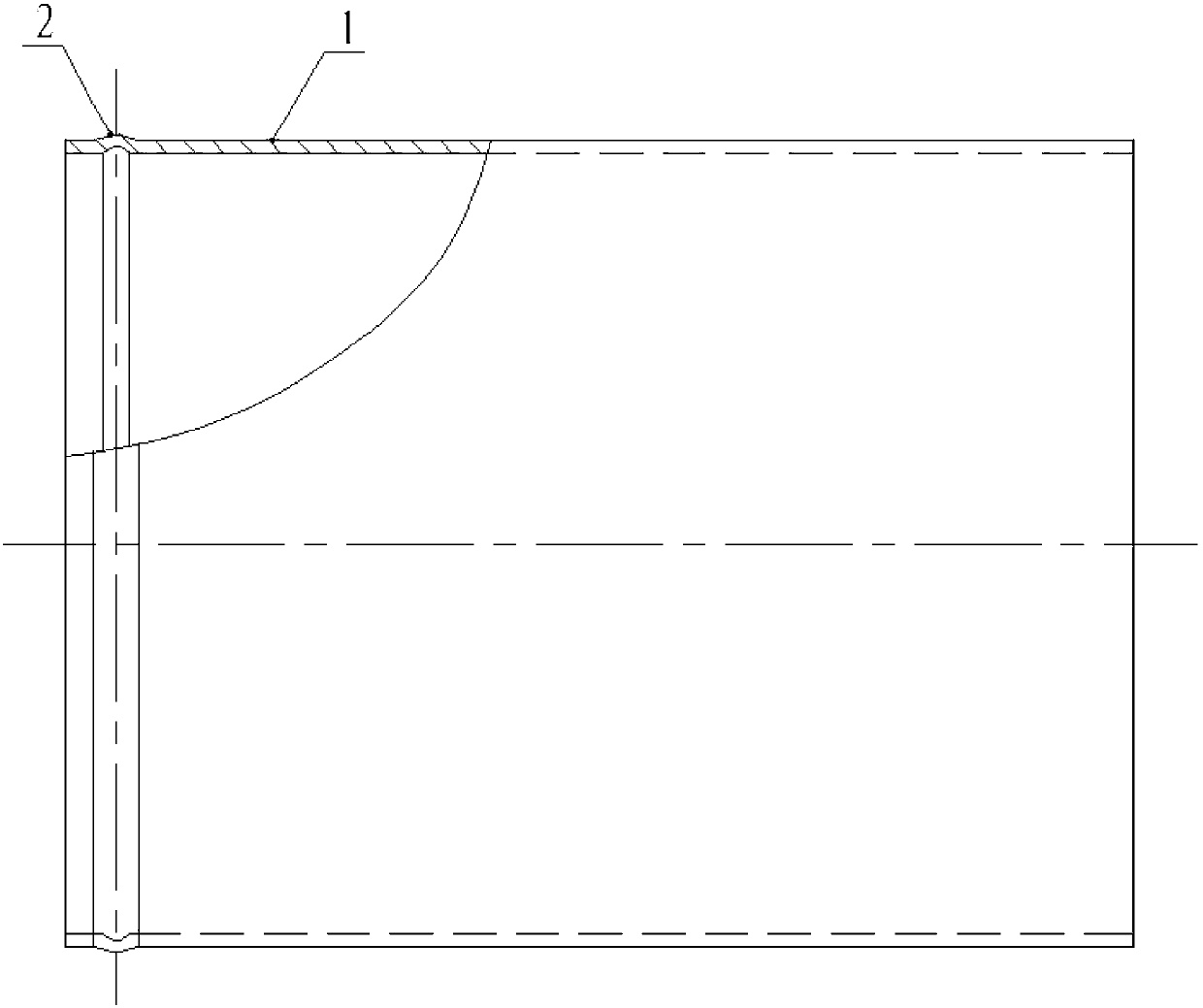

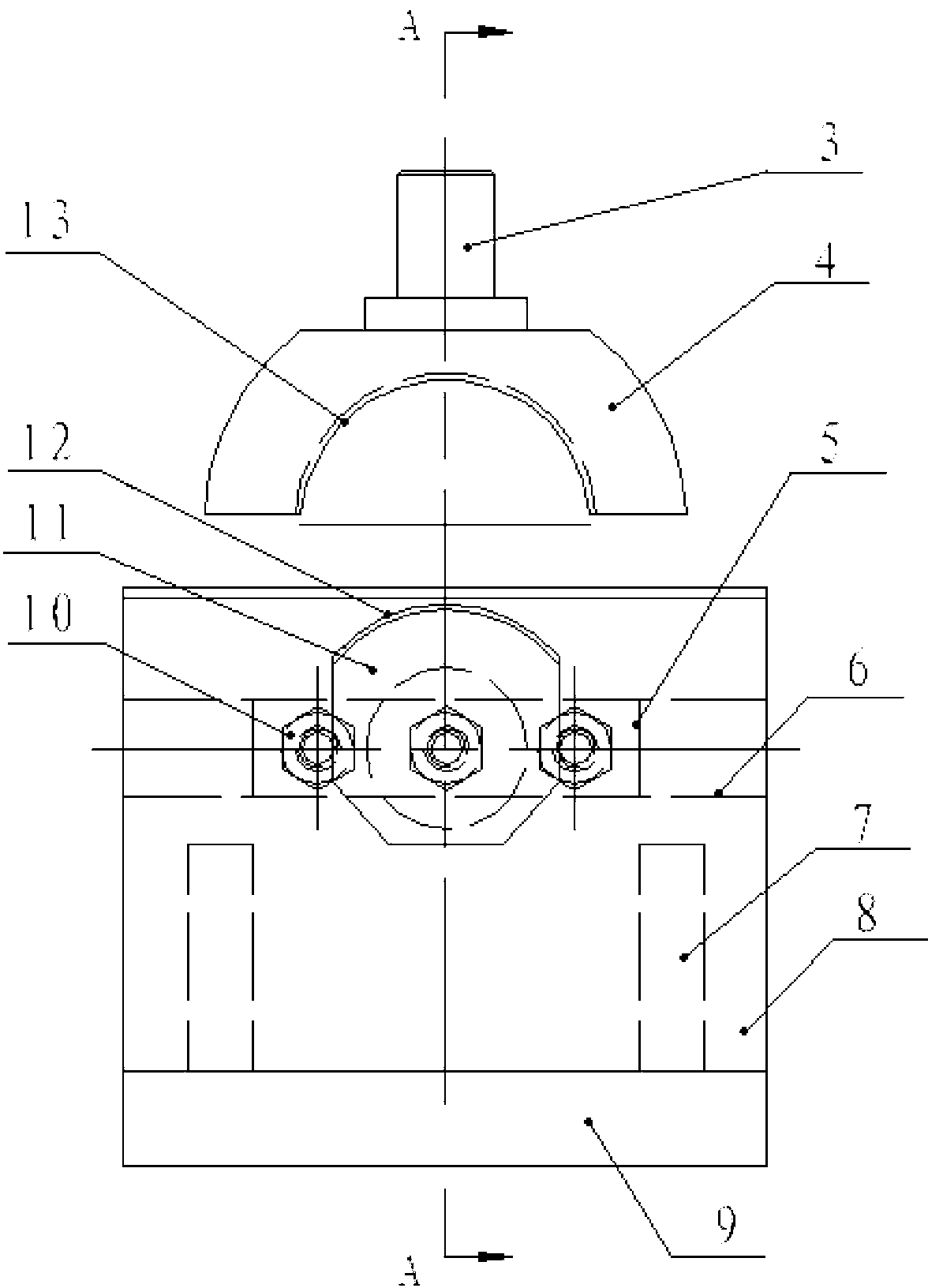

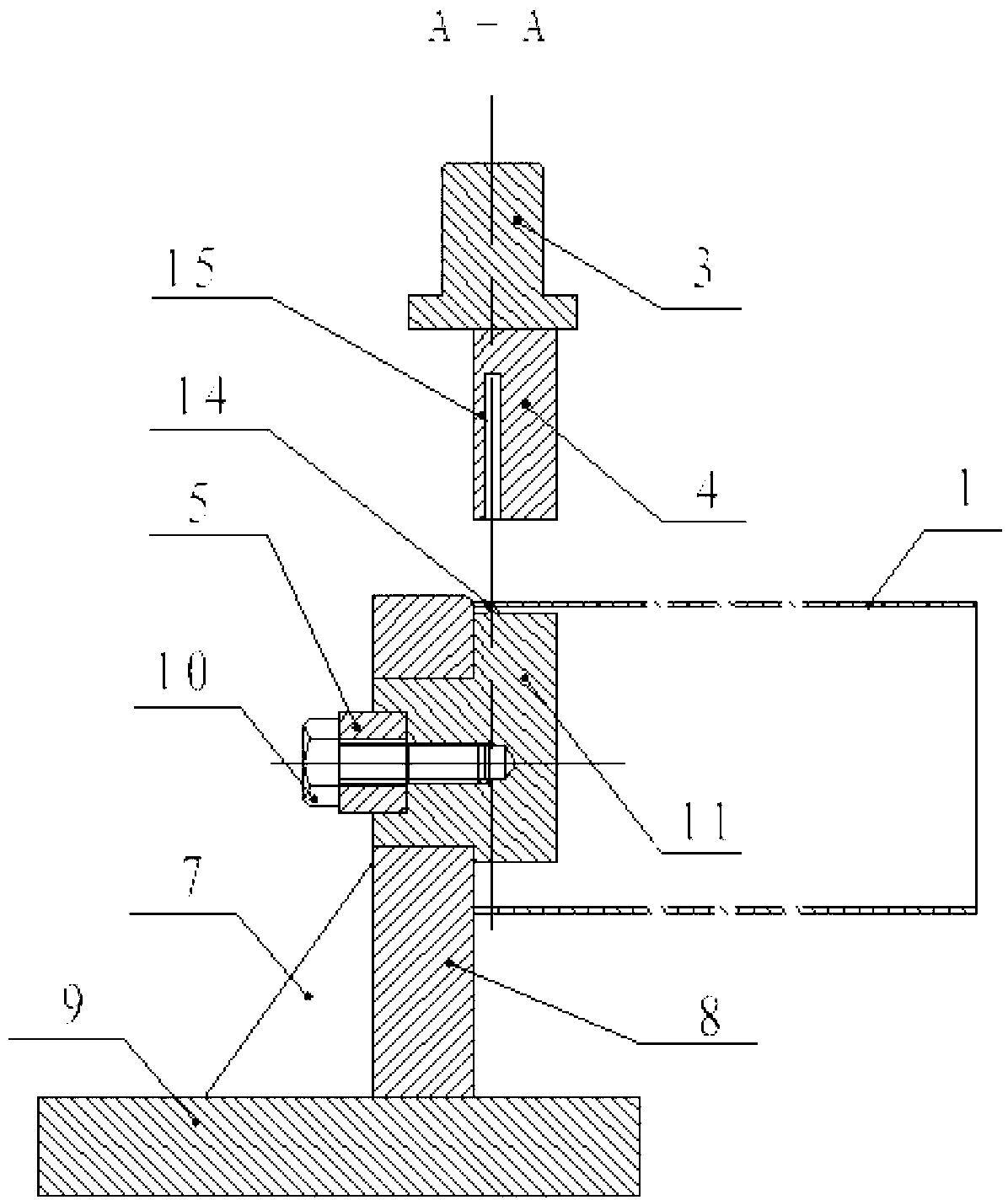

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0020] Stamping dies for forming metal nozzles, such as figure 2 and image 3 Shown, comprise upper mold 4, lower mold 11, lower template 9, lower mold fixed plate 8, mold handle 3.

[0021] Described patrix 4 is installed on the pressure head of stamping equipment, and the upper part of patrix 4 is fixedly connected with mold handle 3, and patrix 4 is connected with pressure head through mold handle 3, realizes up and down movement under the control of pressure head. The lower part of the upper die 4 is provided with a concave pressure surface 13, which is a concave semicircular arc shape matched with the outer diameter of the metal pipe, and a circle of grooves 15 is distributed along the circumference on the concave pressure surface 13 for Form the outer surface of the boss 2 where the mouth of the metal pipe 1 is connected. The dimensions of the concave pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com