Mechanical kinetic energy automatic rise-and-fall netting bracket

A technology of mechanical kinetic energy and bracket, applied in the field of steel cage weaving devices, can solve the problems of steel cage damage, high cylinder maintenance cost, high cylinder cost, high work efficiency, saving maintenance cost and time, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

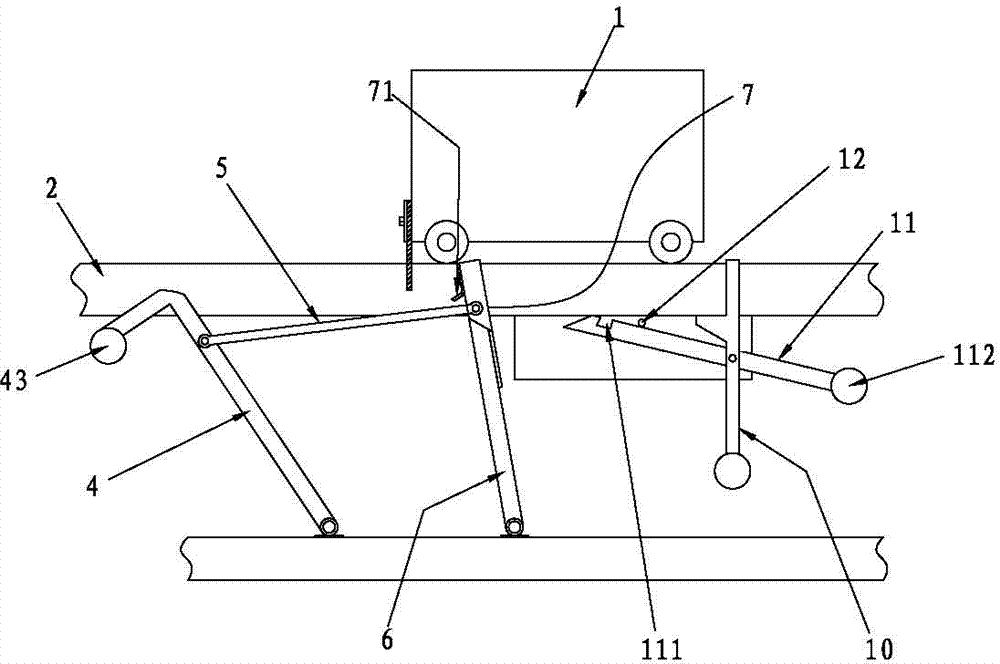

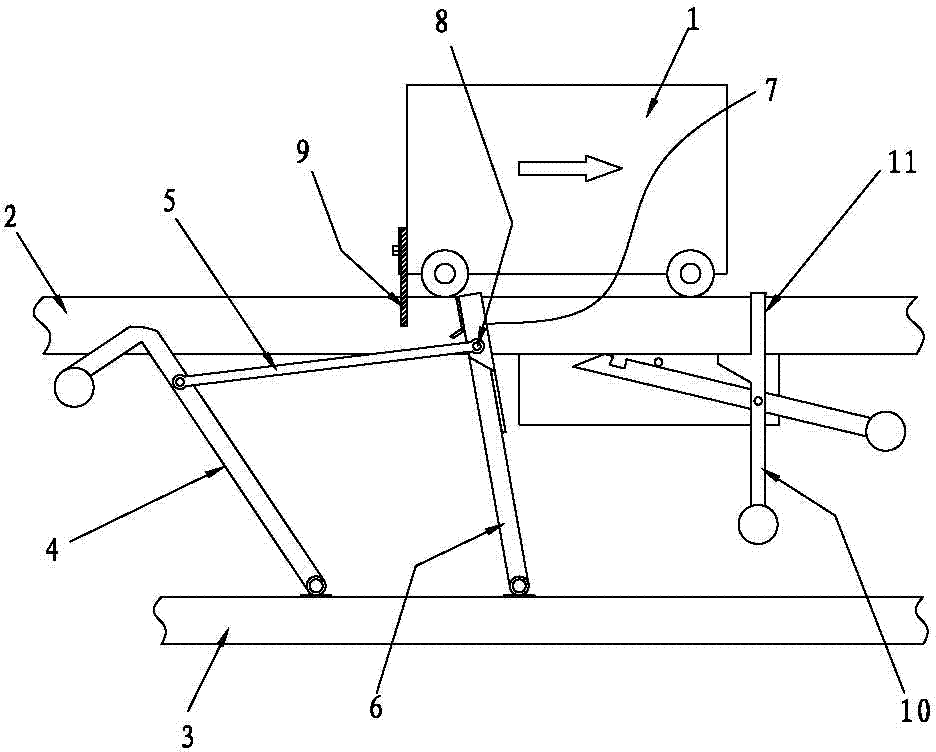

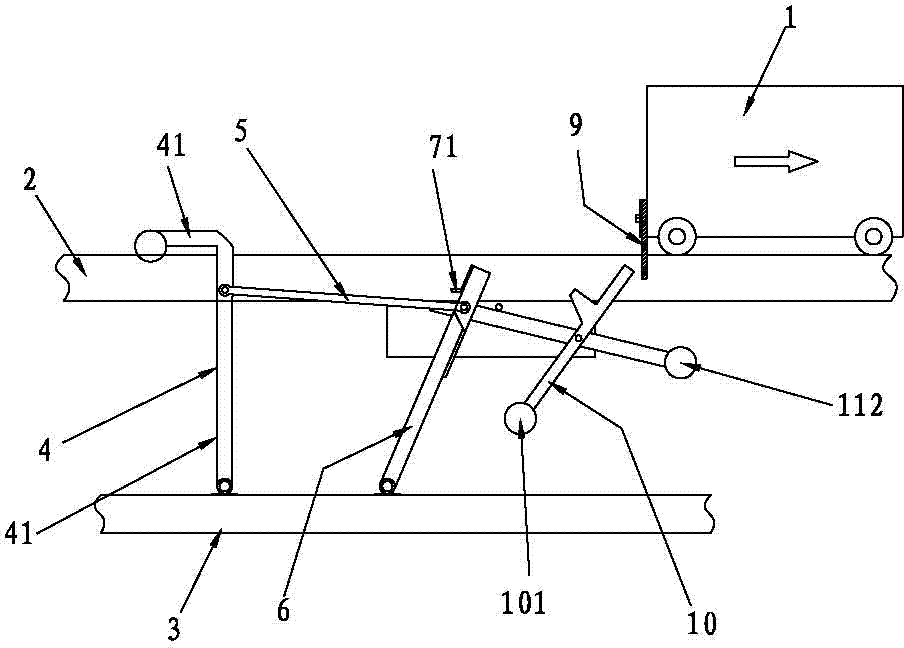

[0022] Such as figure 1 As shown, a mechanical kinetic energy type automatic lifting netting bracket includes a netting trolley 1 with casters on both sides, two guide rails 2, a guide rail base 3 and a bracket 4, the lower end of the bracket 4 is connected to the guide rail base 3 pivot connection, the driving device arranged on the guide rail base 3 cooperates with the bracket 4; the bracket 4 includes two frame bodies, the frame body includes a vertical bar 41 and a cross bar 42, and the cross bar 42 is supported and matched with the steel cage; There is a reset gravity block 43 on the bracket 4 . The reset gravity block 43 is arranged on one end of the cross bar 42 .

[0023] The driving device includes a bracket pull rod 5, a swing rod 6, a one-way flap 7, a tripping plate 71 arranged on the one-way flap 7, a fixed shaft 8, a locking device and a netting trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com