Lawn matrix cake stamping lathe

A substrate and turf technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of simple and convenient operation, cumbersome production process, poor production effect, etc., achieve good effect, simple structural design, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

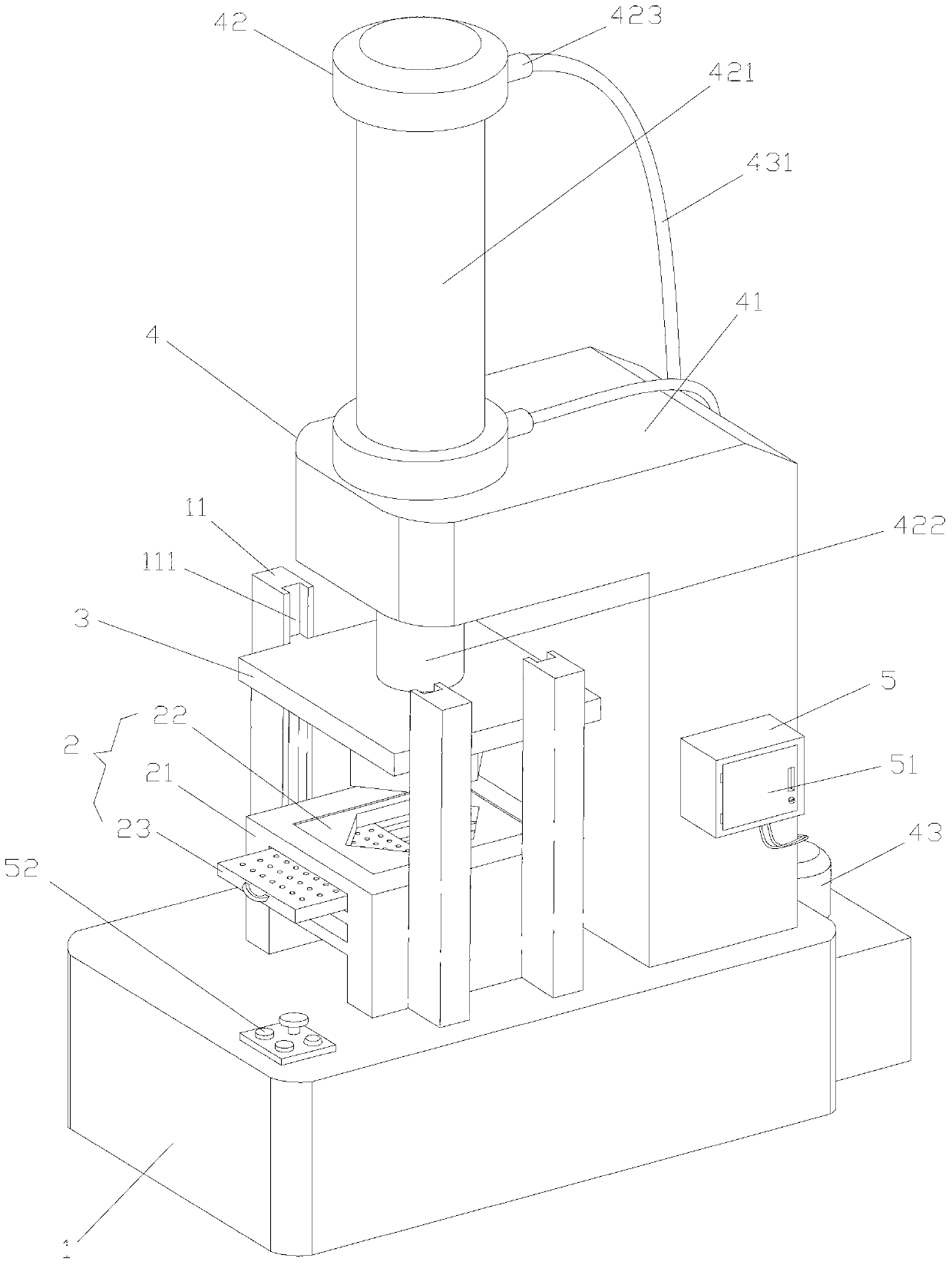

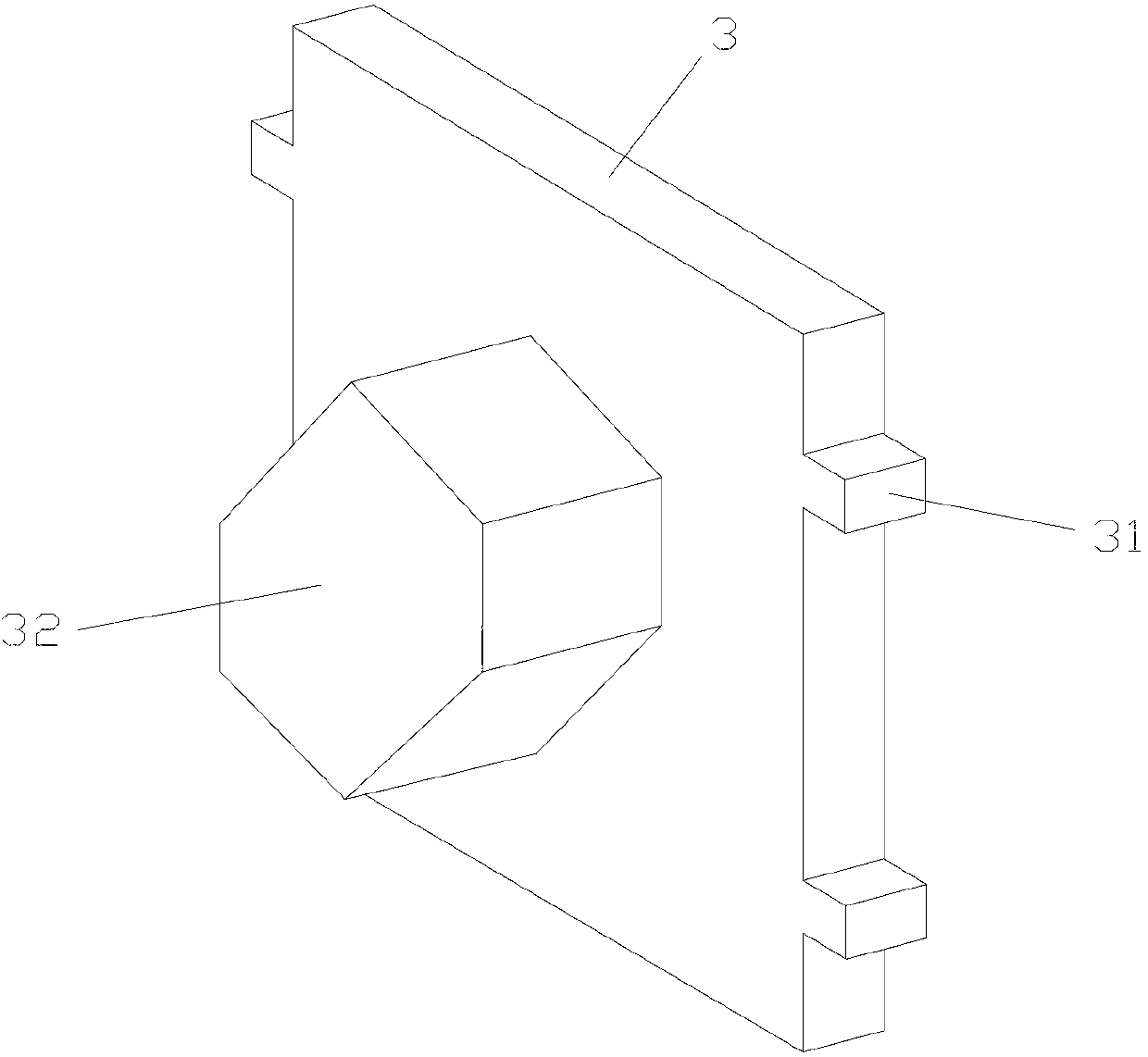

[0018] Such as Figures 1 to 3 As shown, the lawn matrix cake stamping bed of the present invention includes a base 1 , a lower mold 2 , an upper mold 3 , a driving mechanism 4 and a control device 5 .

[0019] The base 1 is roughly in the shape of a cuboid, and a pair of opposite side walls are respectively symmetrically provided with a pair of guide columns 11 .

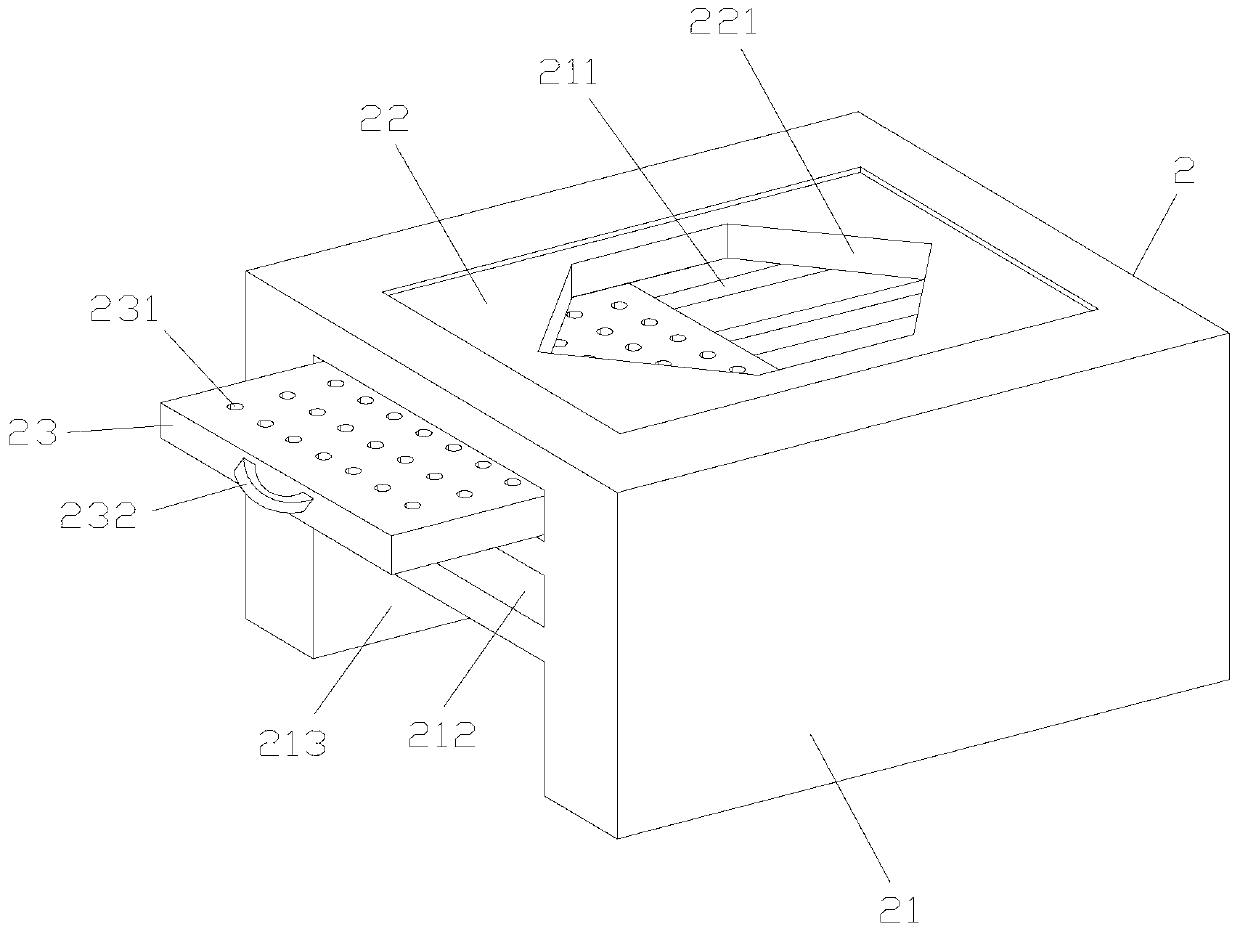

[0020] The lower mold 2 is roughly in the shape of a cuboid, which is arranged in the center of the top of the base 1, and includes a base 21, a template 22, and a pull plate 23, wherein the base 21 is in a roughly cuboid structure and is provided with slideways 211 opposite to a group of inner walls. ; The upper side of one end surface of the base 21 is provided with a socket 212, and the bottom side is provided with a substrate cake outlet 213. In this embodiment, the sockets 212 are two arranged side by side. The template 22 is matched and embedded inside the base 21, and the middle part is provided with a die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com