Turning device and turning method for super-heavy and oversized article

A technology of super large and large objects, which is applied in the field of flipping construction of super large and large objects, can solve the problem that the deformation, deflection and synchronization of objects cannot be effectively controlled, the position or direction of objects cannot be turned over, and the safety and reliability of construction cannot be guaranteed, etc. It can solve the problem of running synchronization, easy to transport and carry, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

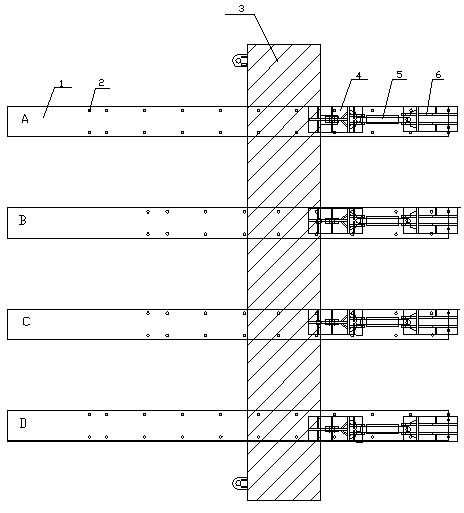

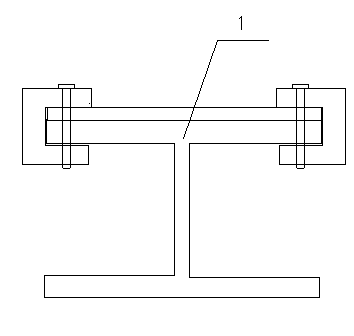

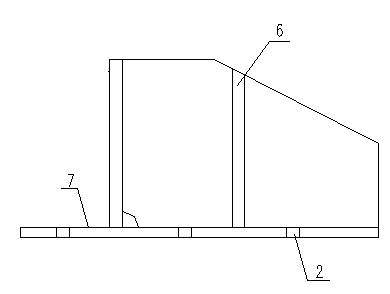

[0034] see Figure 4 , the equipment unit of this embodiment is composed of five parts: a sliding beam 1, a sliding shoe 4, a hydraulic push rod 5, a pushing support 6, and a lifter 8. The sliding beam 1 is an I-shaped steel beam (see figure 2 ), along the length direction of the I-shaped steel beam, there are pin holes 2 arranged at intervals on both sides of the upper flange plate for fixing the push support 6. The sliding beam 1 is the operation of the sliding shoe 4 and the push support 6. The operating platform; the push support 6 is a steel structure, and the two sides of the bottom plate 7 of the steel structure are drilled with pin holes 2 corresponding to the pin holes 2 on the sliding beam 1 (see i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com