Waste concrete reclaimed tunnel back lining grouting material and preparation method thereof

A technology of waste concrete and grouting materials, which is applied in the field of building materials, can solve problems affecting the safety of tunnel structures, loss of filling function of grout, lack of design and evaluation, etc., and achieve convenient construction management, low production costs, and prevention of leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

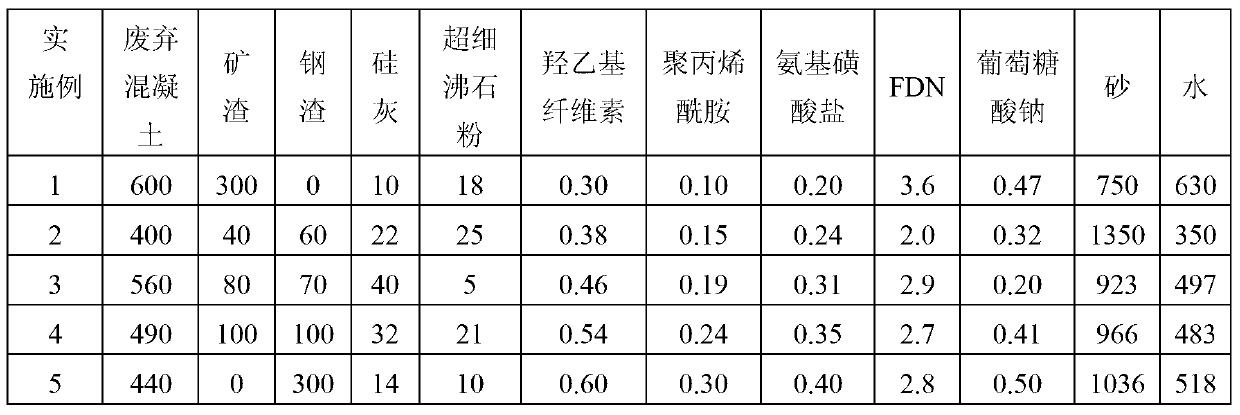

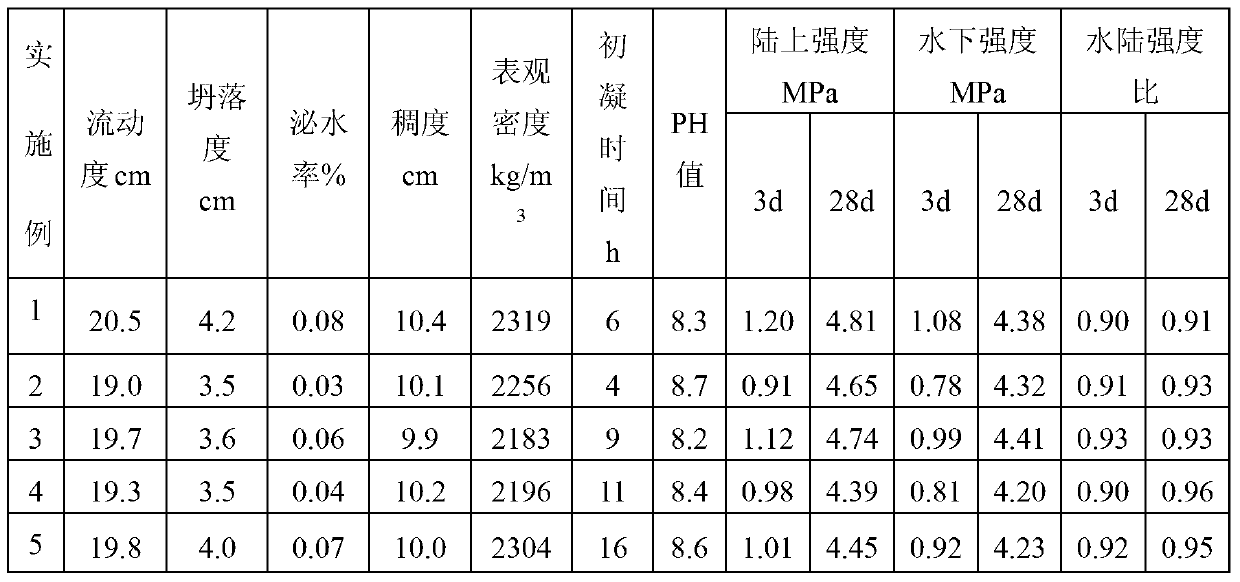

[0025] A tunnel backing grouting material prepared by using waste concrete. The preparation process includes the following steps: first, weigh silica fume, ultrafine zeolite powder, hydroxyethyl cellulose, polyacrylamide, sulfamic acid Salt, naphthalene-based water-reducer and sodium gluconate are uniformly mixed and packaged for storage to obtain externally mixed component B; the waste concrete, slag, steel slag, sand and water weighed according to the distribution ratio of each component are mechanically mixed (stirring 2 minutes) to obtain the matrix component A; then mix the external component B into the matrix component A and stir for 3 minutes to obtain a tunnel backing grouting with high water resistance, high water reduction and plastic retention Material (“toothpaste” like), immediately stored in slurry storage tanks to be transported to the TBM site for infusion. The distribution ratio of each group in Examples 1-5 is shown in Table 1.

[0026] Wherein, the waste co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com