Soybean oil based elastomer raw rubber, soybean oil based elastomer and preparation method thereof

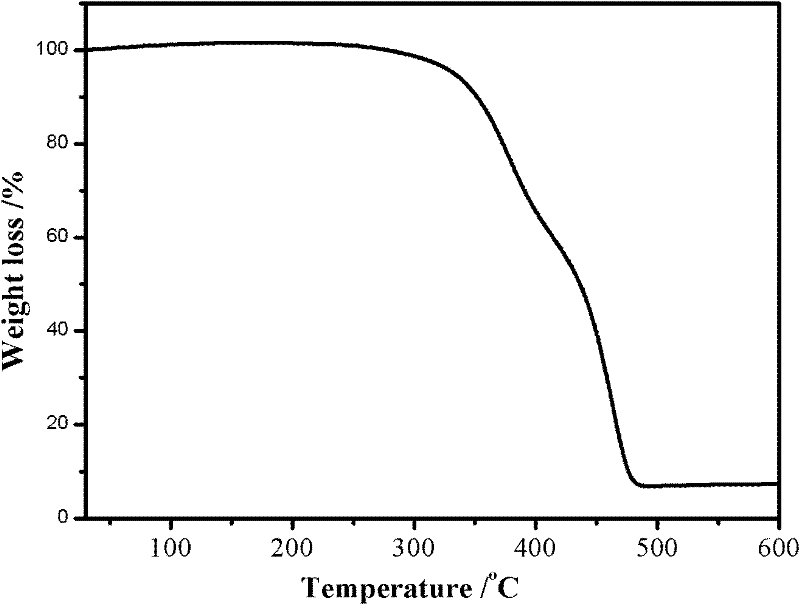

A soybean oil-based, body raw rubber technology, applied in the field of polymer materials, can solve the problems of application limitation, low mechanical strength of materials, inability to further process, etc., and achieve the effects of improved mechanical properties, good thermal stability, and good oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

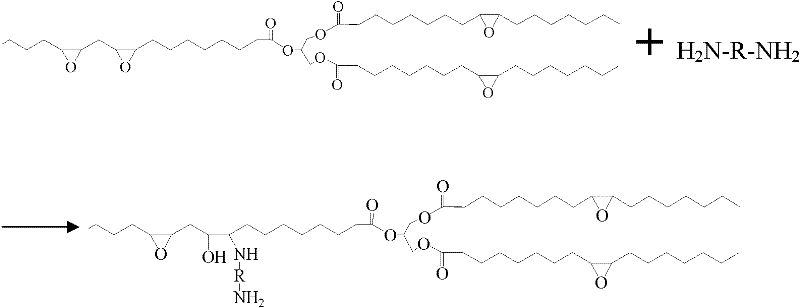

Method used

Image

Examples

Embodiment 1

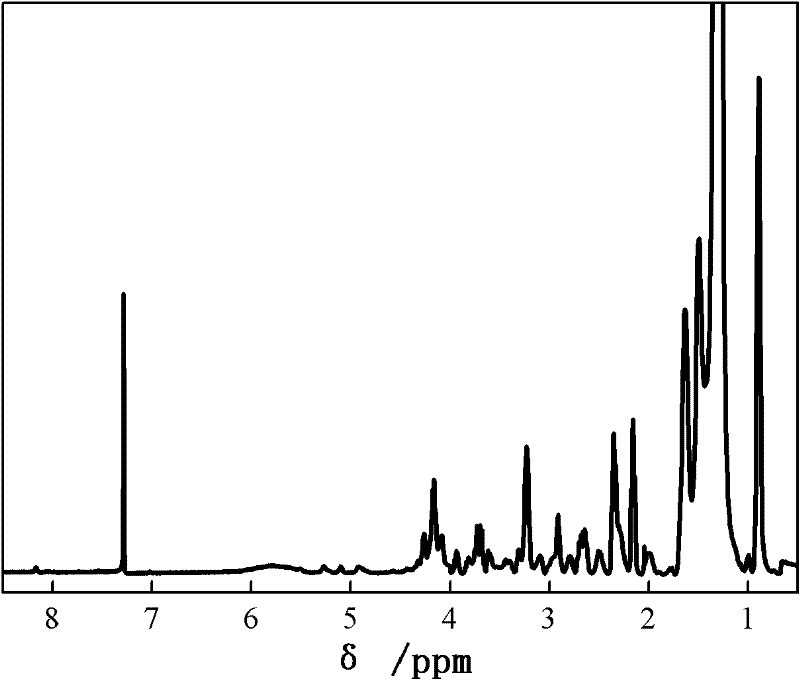

[0024] Embodiment 1: Preparation of epoxy soybean oil-decanediamine-succinic anhydride elastomer

[0025] Add 100 g of epoxidized soybean oil (epoxy value 6.0, the same below) and 36 g of decanediamine into a three-necked bottle, heat to 120 ° C, and pass N 2 Protected, reacted for 8 hours under stirring conditions, took it out, and dried it in a vacuum oven at 60°C for 5 hours to obtain the desired raw rubber. Its weight-average molecular weight is 165,000 as measured by a multi-angle laser light scattering instrument, and its glass transition temperature is -18°C as measured by differential scanning calorimetry.

[0026] Blend 100g of the above-mentioned raw rubber with 7g of succinic anhydride on an open mill for 15 minutes, and then place it on a flat vulcanizer for tableting at a temperature of 160°C for 70 minutes to obtain the desired elastomer.

Embodiment 2

[0027] Embodiment 2: Preparation of epoxy soybean oil-butylene diamine-sebacic acid elastomer

[0028] Add 100g of epoxidized soybean oil and 16g of butanediamine into a three-necked flask, heat to 120°C, and pass N 2 Protected, reacted for 6 hours under stirring conditions, took it out, and dried it in a vacuum oven at 60°C for 5 hours to obtain the desired raw rubber. Its weight-average molecular weight is 185,000 as measured by a multi-angle laser light scattering instrument, and its glass transition temperature is -15° C. as measured by differential scanning calorimetry.

[0029] Blend 100g of the above-mentioned raw rubber with 11g of sebacic acid and 60g of carbon black (N550) on an open mill for 25 minutes, then place it on a flat vulcanizer and press it into tablets at a temperature of 170°C for 40 minutes to obtain the desired elasticity. body.

Embodiment 3

[0030] Embodiment 3: the preparation of epoxy soybean oil-tetradecanediamine-maleic anhydride elastomer

[0031]Add 100g of epoxidized soybean oil and 40g of tetradecanediamine into a three-necked flask, heat to 120°C, pass N 2 Protected, reacted for 18 hours under stirring conditions, took it out, and dried it in a vacuum oven at 60°C for 5 hours to obtain the desired raw rubber. Its weight-average molecular weight is 78,000 as measured by a multi-angle laser light scattering instrument, and its glass transition temperature is -28°C as measured by differential scanning calorimetry.

[0032] Blend 100g of the above-mentioned raw rubber with 9g maleic anhydride and 60g white carbon black (DM10) on an open mill for 25min, and then place it on a flat vulcanizer for tableting at a temperature of 180°C for 30min to obtain the desired elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com