Water boiler heating-net without water consumption

A technology for consuming water and boilers, applied in the field of operation technology of water boiler heating network, can solve problems such as reducing economic benefits, poor water management, waste of resources, etc., and achieve the effects of improving economic benefits, reducing production costs, and alleviating energy shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

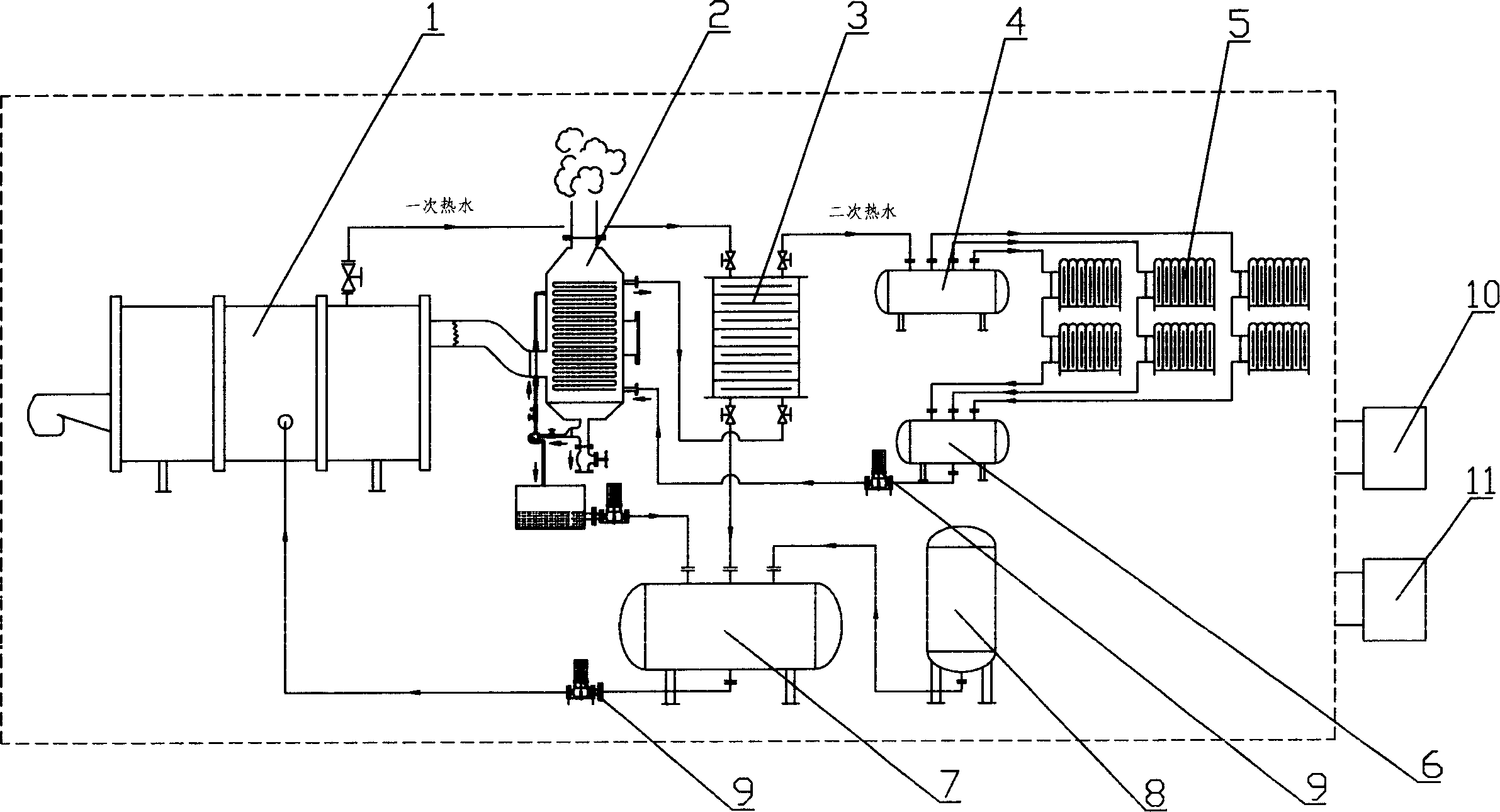

[0011] Such as figure 1 As shown, the water boiler heating network that does not consume water adopts a closed operation process for the water boiler heating network, and the heating unit (including boiler 1, flue gas condenser 2, heat exchanger 3, boiler make-up water tank 7, softened water Processor 8 and water pump 9) and heating unit (comprising heat exchanger 3, flue gas condenser 2, sub-water tank 4, heating equipment 5, water collecting tank 6 and water pump 9) are closed and connected through pipelines respectively, so that water It is not exposed to the atmosphere and is recycled independently in the two units. That is to say, the water used as the heat medium in the two cycles of boiler 1 heating and hot water heating is strictly separated. One boiler water, that is, the primary hot water is heated. The secondary hot water, the secondary hot water is sent to the heating equipment 5 through the pipeline through the water distribution tank 4, and the secondary hot wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com