A kind of polyurethane elastomer with bio-based amorphous multi-polyester as soft segment and preparation method

A technology of polyurethane elastomer and multi-polyester, which is applied in the field of polymer materials, can solve the problems of low temperature resistance and poor flexibility, and achieve the effect of improving elongation at break, enriching varieties, and broadening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

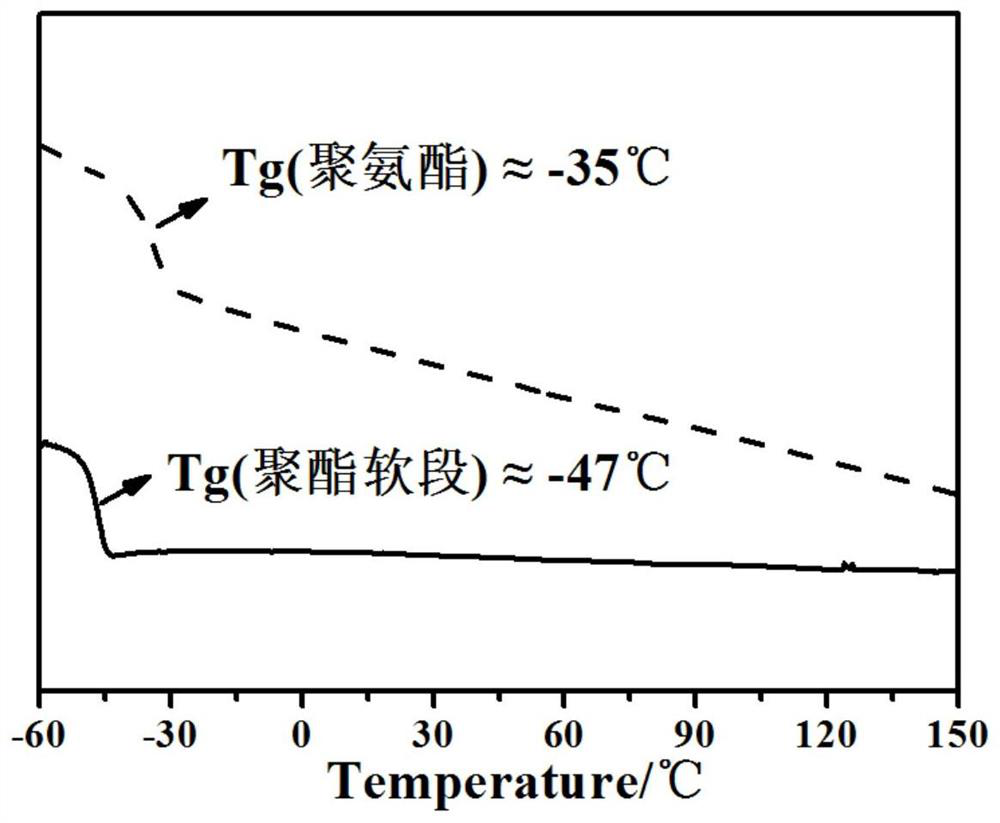

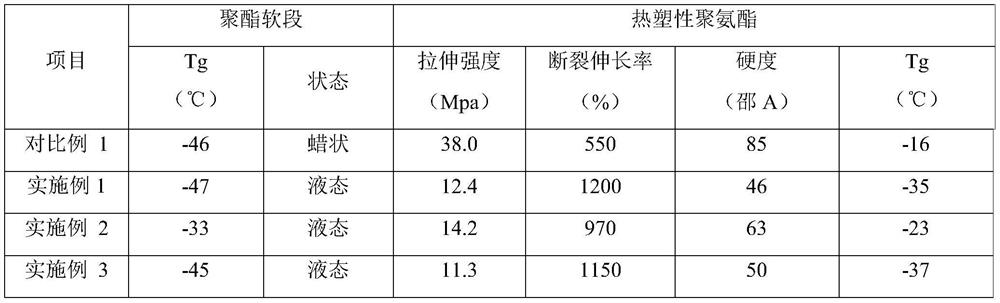

[0045] Preparation method of bio-based poly polyester soft segment: the ratio of bio-based 1,3-propanediol, 2,3-butanediol, succinic acid, sebacic acid massage ratio of 1.1 / 0.3 / 0.7 / 0.3 (alkoxide ratio 1.4:1) was added to a 250mL four-mouth flask, heated to 170 °C, esterified for 3 hours; then added catalyst tetrabutyl titanate (the amount of catalyst accounted for 0.03% of the total mass of diol and dibasic acid), the temperature was adjusted to 220 °C, The vacuum reaction is 1 hour to obtain a number of amorphous polyesters with an average molecular weight of 4000 hydroxyl ends.

[0046]Preparation method of polyurethane prepolymer: in a four-mouth flask of 100mL, the hydroxyl-terminated polyester was stirred at 80 °C, vacuum for 2 hours, and then cooled down to 70 °C, and the metered (the molar ratio of the polyester soft segment and diisocyanate is 1:2, the mass ratio of the soft and hard segment is 87 / 13) diphenylmethane diisocyanate, the reaction is 3 hours, to obtain the pre...

Embodiment 2

[0050] Preparation method of bio-based poly polyester soft segment: the ratio of bio-based ethylene glycol, 1,3-propanediol, succinic acid, adipic acid, yikang acid massage ratio of 0.80 / 0.80 / 0.63 / 0.27 / 0.10 (alkoxide ratio 1.6:1) was added to a 250mL four-mouth flask, heated to 180 °C, esterified for 2 hours; then added catalyst paratobenzenesulfonic acid (the amount of catalyst accounted for 0.06% of the total mass of diol and dibasic acid), the temperature was adjusted to 200 °C, The vacuum reaction was carried out for 2.5 hours to obtain several amorphous polyesters with an average molecular weight of 5000 hydroxyl ends.

[0051] Preparation method of polyurethane prepolymer: In a four-mouth flask of 100mL, the hydroxyl-terminated polyester was stirred at 90 °C, vacuum for 3 hours, and then cooled down to 75 °C, and the metered (the molar ratio of the polyester soft segment and diisocyanate is 1:5, the mass ratio of the soft and hard segment is 79 / 21) 1,5-naphthalene diisocyana...

Embodiment 3

[0055] Preparation method of bio-based polyestride soft segment: the proportion of bio-based ethylene glycol, 1,4-butanediol, 1,10-decanediol, succinic acid, sebacic acid massage ratio of 0.75 / 0.6 / 0.15 / 0.8 / 0.2 (alkyd ratio 1.5:1) was added to a 250mL four-mouth flask, heated to 190 °C, esterified for 2 hours; then added catalyst tetraisopropyl titanate (the amount of catalyst accounted for 0.04% of the total mass of diol and dibasic acid), the temperature was adjusted to 210 °C, The vacuum reaction is carried out for 3 hours to obtain several amorphous polyesters with an average molecular weight of 6000 hydroxyl ends.

[0056] Preparation method of polyurethane prepolymer: In a 100mL four-mouth flask, the hydroxyl-terminated polyester was stirred at 95 °C, vacuum for 2 hours, and then cooled down to 80 °C, and the metered (the molar ratio of the polyester soft segment and diisocyanate was 1:4, the mass ratio of the soft and hard segment was 82 / 18) dicyclohexylmethane diisocyanate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com