Technology for preparing enoxaparin sodium by membrane separation

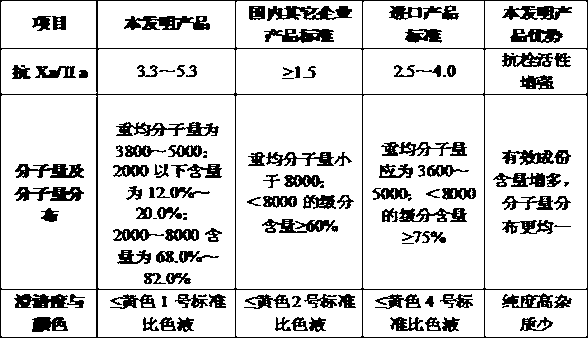

A technology of enoxaparin sodium and heparin sodium, which is applied in the field of bioengineering, can solve the problems of recycling waste ethanol, uneven molecular weight of target products, and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

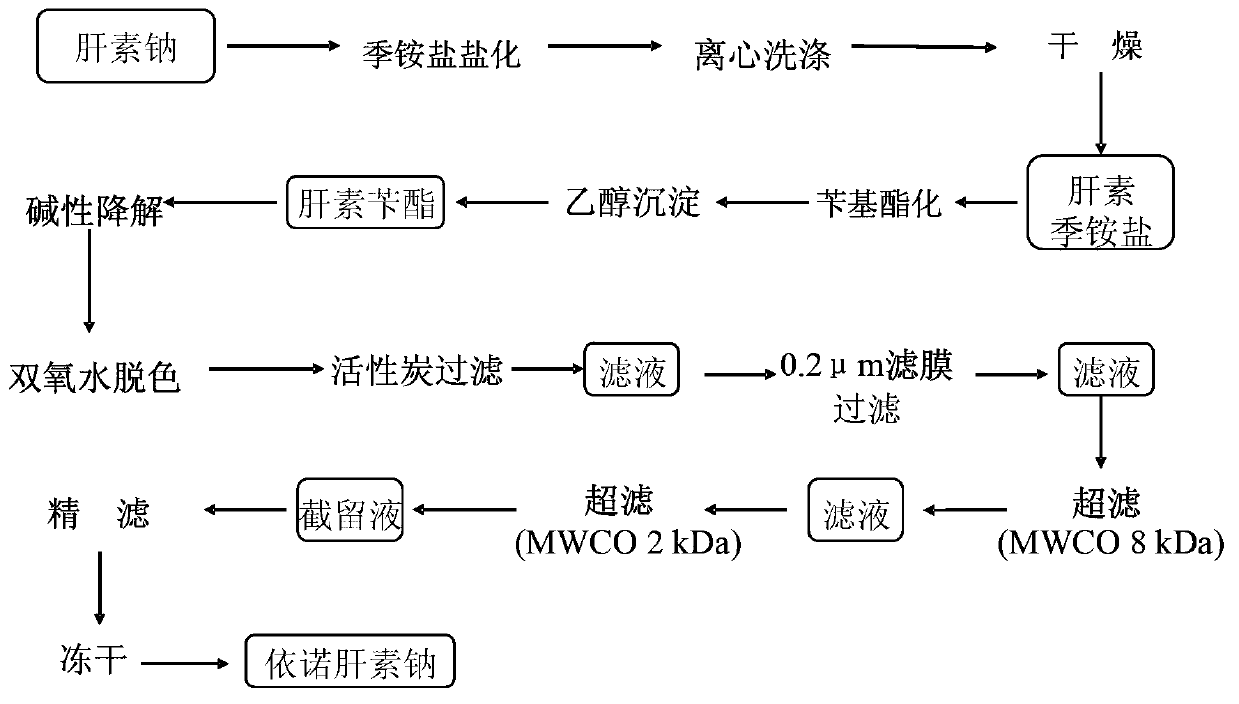

[0021] Embodiment 1: as figure 1 as shown,

[0022] a. Preparation of heparin-benzethonium chloride salt by hydrophilic reaction system

[0023] Add 3kg of heparin sodium (injection grade de-DS) to 30 liters of purified water at 30-40°C and stir to dissolve it completely; add 8kg of benzethonium chloride to 50 liters of purified water at 45-50°C and stir to dissolve it completely. Then slowly add the dissolved heparin sodium solution into the dissolved benzethonium chloride solution under stirring, after the addition is completed, keep stirring at 45-50°C for 30-60 minutes, centrifuge the resulting precipitate, and discard the supernatant , to obtain heparin salt. After washing the heparin salt with 100 liters of purified water, centrifuge to discard the supernatant, repeat the washing and centrifugation operation for 3 to 4 times, turn on the hot air circulation oven, and dry the centrifuged heparin salt in the oven at 50-60°C After 18 to 24 hours, heparin hydrochloride wi...

Embodiment 2

[0035] Embodiment 2: the difference between this embodiment and embodiment 1 is:

[0036] a. Preparation of heparin-benzethonium chloride salt by hydrophilic reaction system

[0037] Add 5kg of heparin sodium (injection grade de-DS) to 50 liters of purified water at 30-40°C and stir to dissolve it completely; add 13kg of benzethonium chloride to 85 liters of purified water at 45-50°C and stir to dissolve it completely. Then slowly add the dissolved heparin sodium solution into the dissolved benzethonium chloride solution under stirring, after the addition is completed, keep stirring at 45-50°C for 30-60 minutes, centrifuge the resulting precipitate, and discard the supernatant , to obtain heparin salt. After washing the heparin salt with 100 liters of purified water, centrifuge to discard the supernatant, repeat the washing and centrifugation operation for 3 to 4 times, turn on the hot air circulation oven, and dry the centrifuged heparin salt in the oven at 50-60°C After 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com