Production technology of super stain-resistant waterborne compound coating

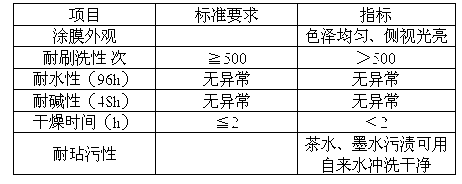

A production process and composite coating technology, which is applied in the direction of coating, etc., can solve the problems of affecting the urban appearance, affecting the appearance of the building, and the structure is not compact, and achieves the effects of small water absorption, improved economic benefits, and good stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. Preparation:

[0015] rutile nano-TiO 2 Process it until the average particle size is 80nm, and then use it.

[0016] Weigh 12kg of styrene-acrylic emulsion, 2.6kg~3.0kg of nano-TiO 2 , 2.2 kg SiO 2 , 0.5 kg inorganic antibacterial and antifungal agent, 1.2 kg negative ion generating powder, 0.2 kg cellulose, 2.9 kg AS881 superfine aluminum silicate, 40 kg filler, 0.8kg film-forming aid, 0.6kg dispersant, 0.4kg thickener , 0.5kg stain resistance agent and 0.7kg viscosity stabilizer.

[0017] The raw material inorganic antibacterial antifungal agent contains Ag + and Cu 2+ , Ag + Accounting for 2.8% of the mass of inorganic antibacterial and antifungal agents, Cu 2+ It accounts for 1.7% of the mass of inorganic antibacterial and antifungal agents.

[0018] 2. Processing technology:

[0019] First, the styrene-acrylic emulsion, additives (composed of film-forming additives, dispersants, thickeners, stain-resistant agents and viscosity stabilizers), nano-TiO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com