Device conducting false twisting on cotton yarns

A false twisting and cotton yarn technology, applied in textiles and papermaking, etc., can solve the problems of high production energy consumption, inconvenient operation and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

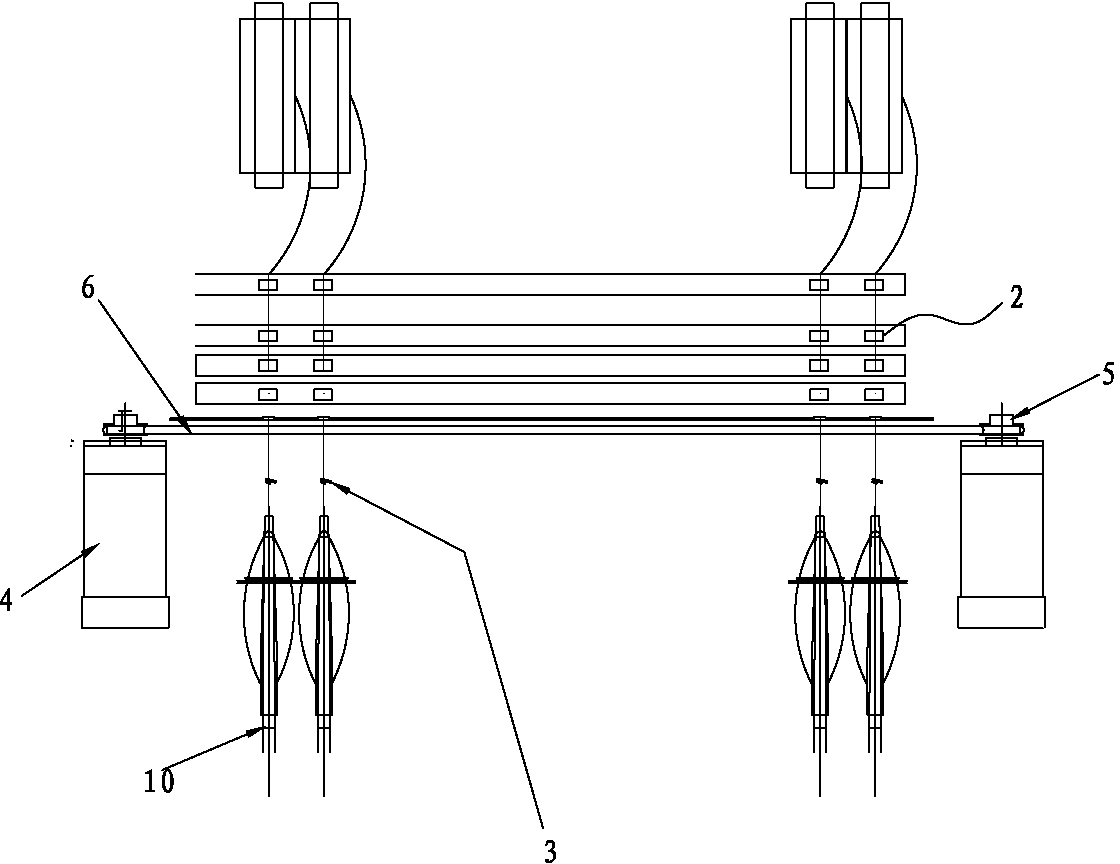

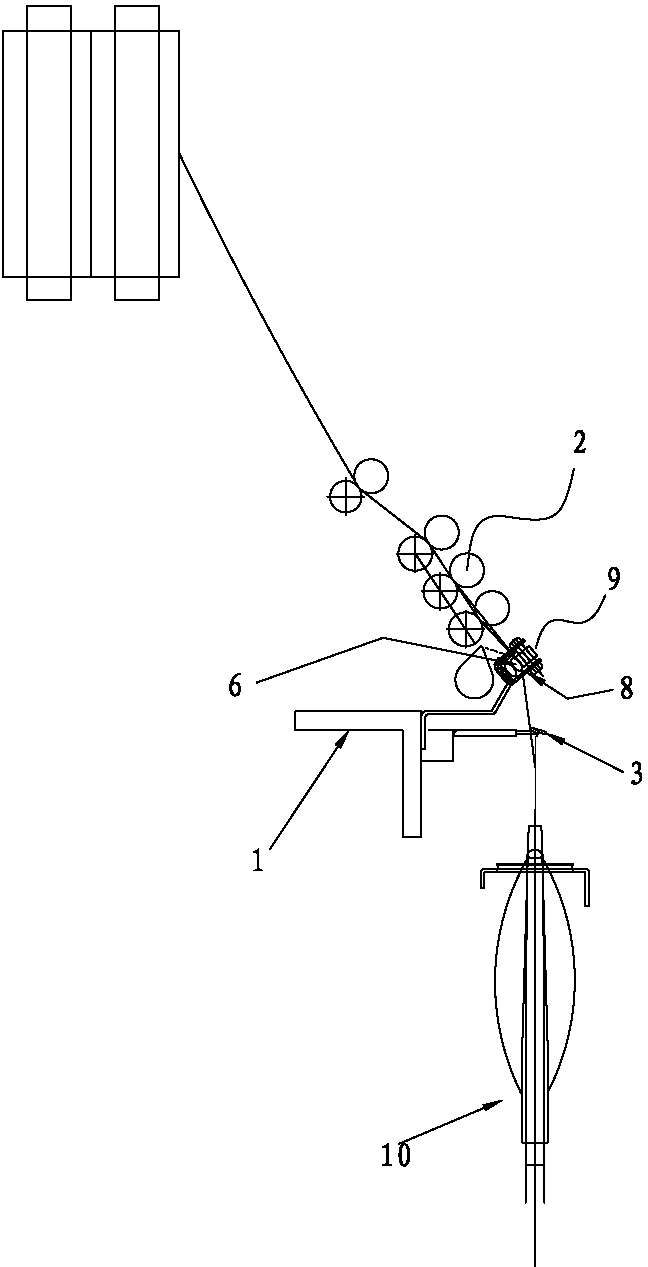

[0017] Such as figure 1 , figure 2 As shown, a device for false-twisting cotton yarn includes a mounting base 1, several pairs of rollers 2, yarn-guiding ceramic parts 3, a false-twisting motor 4, a pulley 5, a false-twisting long belt 6 and a twisting spindle 10; It includes a bracket 7 and a rotary pressing device, the bracket 7 is arranged between the roller 2 and the yarn guide ceramic piece 3;

[0018] There are several rotating and pressing devices evenly distributed on the bracket 7, and the bracket 7 is fixed on the mounting seat 1; the false twisted long belt 6 is matched with the rotating and pressing device.

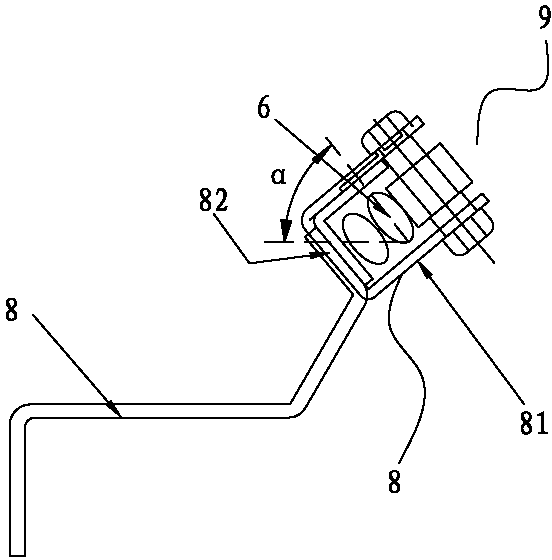

[0019] The rotating and pressing device comprises a U-shaped pivot seat 8 and a pressing rotating member 9, and the pressing rotating member is pivotally connected with the two frame plates 81 of the U-shaped pivoting seat 8; Between the tight rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com