Pavement grooving machine

A slotting machine and cutter head technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of affecting the dust removal effect, increasing the use cost, and reducing work efficiency, and achieves high work efficiency, low use cost and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

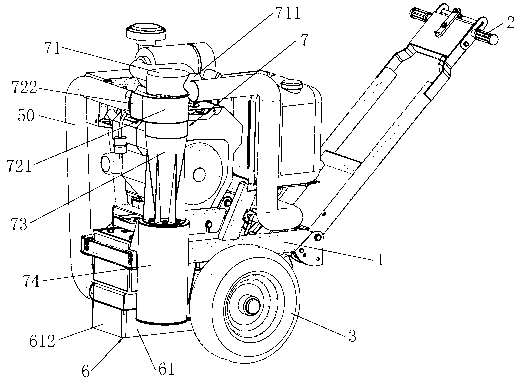

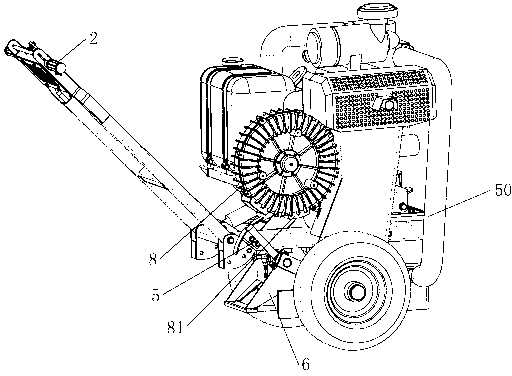

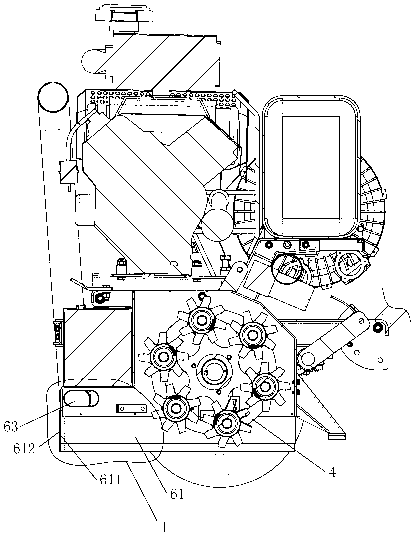

[0022] The present invention is a pavement slotting machine, such as figure 1 , 2 , 3, 8, 9, and 10, including a vehicle frame 1, a handle 2, a traveling wheel 3, a cutter head 4 driven by a motor, a lifting mechanism 5 and a dust removal device. Here, the dust removal device includes a cover Dustproof cover 6, cyclone type dust collector 7 and air pump 8 outside cutterhead 4, described dustproof cover 6 includes the sealing rubber 61 that covers around the cutterhead and the connecting plate 62 that connects these rubbers; The cyclone dust collector 7 includes an outlet filter area 71, a cyclone separator composed of a vortex inlet area 72 and a conical centrifugal area 73, and a dust precipitation area 74 from top to bottom; 71 and the vortex inlet area 72 are provided with a dividing plate 75 and are communicated by a circular communication pipe 76 passing through the dividing plate 75; the large cone end and the small cone end of the conical centrifugal area 73 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com