A centering calibration device for a sensor-rotating swing-arm profiler measuring head

A technology for calibrating devices and profilometers, applied to measuring devices, optical devices, instruments, etc., can solve problems such as no centering method and inability to reflect surface shape errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

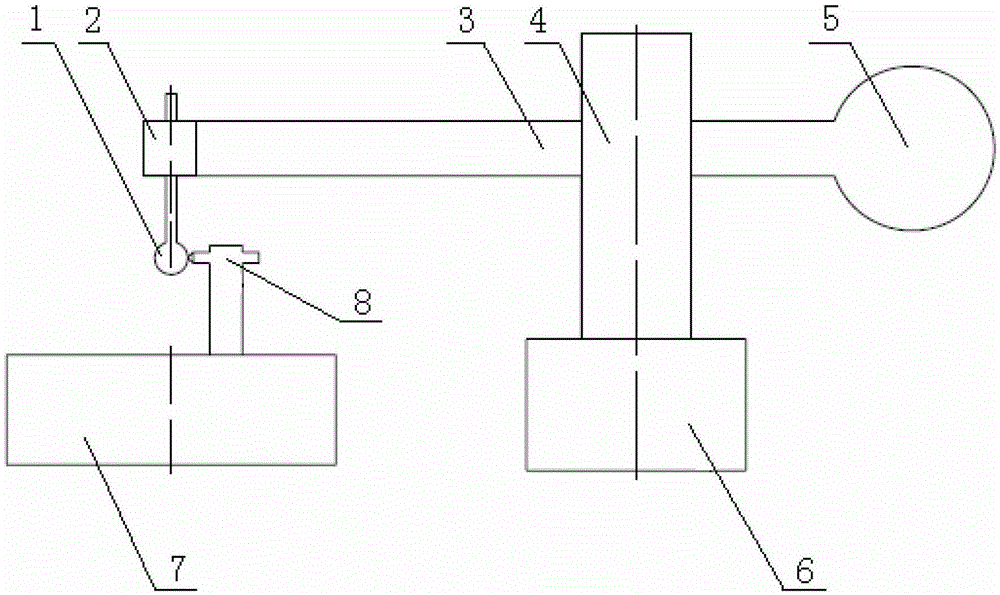

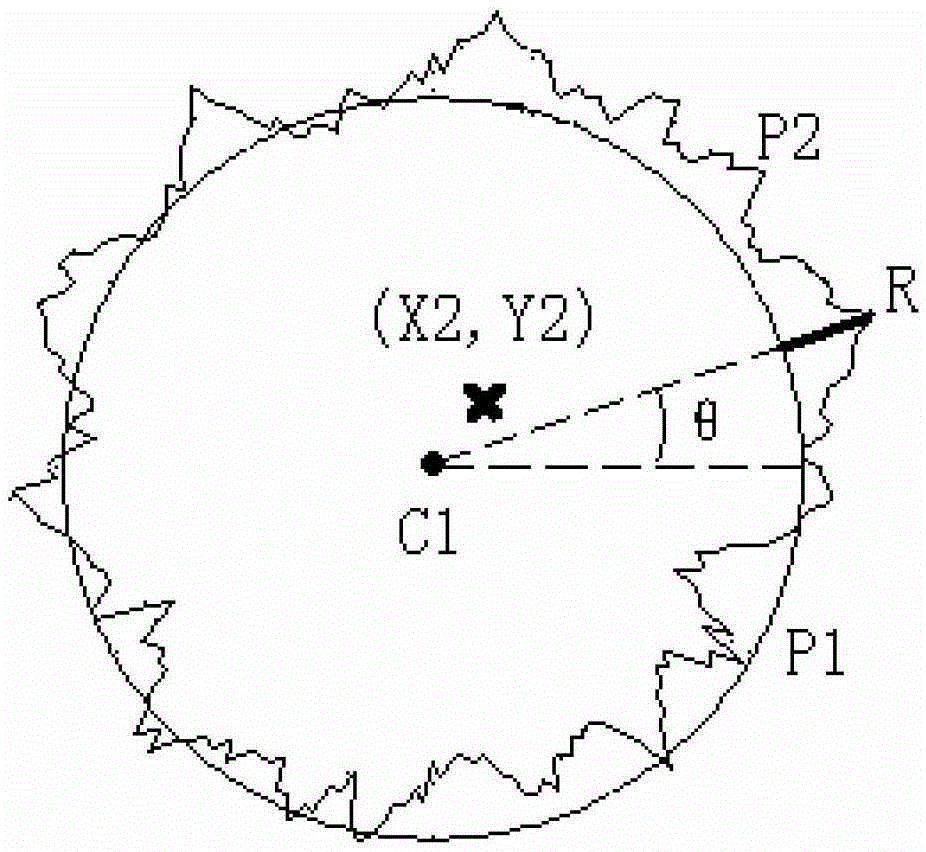

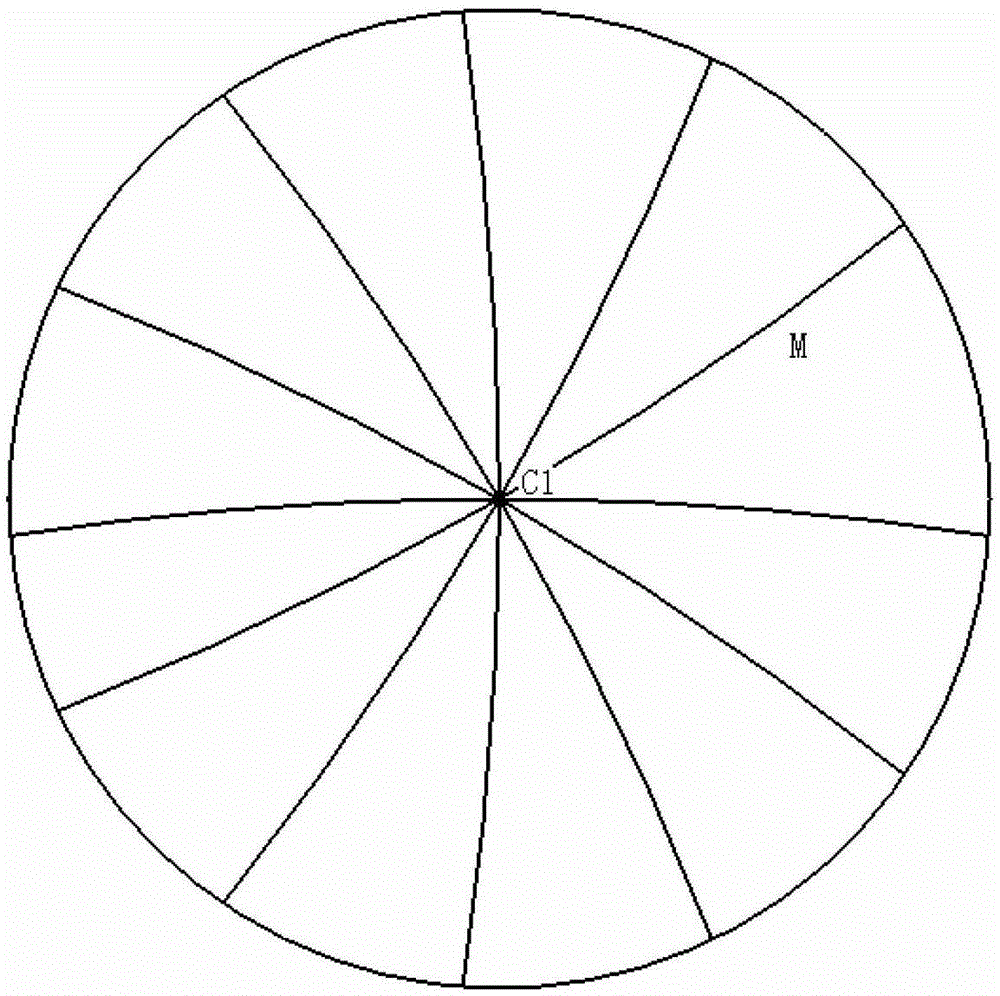

[0026] Such as figure 1 As shown, it is a schematic structural diagram of the centering calibration device of the swing arm profiler probe with sensor rotation, including the profiler probe 1, the profiler probe fine-tuning mechanism 2, the cross arm 3, the column 4, the counterweight 5, and the cross arm turntable 6. The workpiece turntable 7 and the optical probe 8. The profilometer probe 1 is a high-precision contact probe with a resolution of 25nm and a measurement accuracy of 50nm. The fine-tuning mechanism 2 of the profiler measuring head can realize the fine-tuning of 5 degrees of freedom of X, Y, Z, pitch and yaw. The cross arm 3 and the column 4 are used to connect the cross arm turntable 6 and the profilometer probe 1 to complete the rotary motion of the profilometer probe 1 . The counterweight 5 is used to balance the profiler probe 1 , the profiler probe fine-tuning mechanism 2 and the cross arm 3 to ensure that the cross arm turntable 6 maintains a stable rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com