Method for observing rusted cracks of reinforced concrete based on two-stage rust crack model

A reinforced concrete, two-stage technology, applied in the direction of material inspection products, etc., can solve problems such as affecting accurate measurement, inability to observe and measure the thickness of rusted concrete reinforcement rust layer, and rupture of concrete protective layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

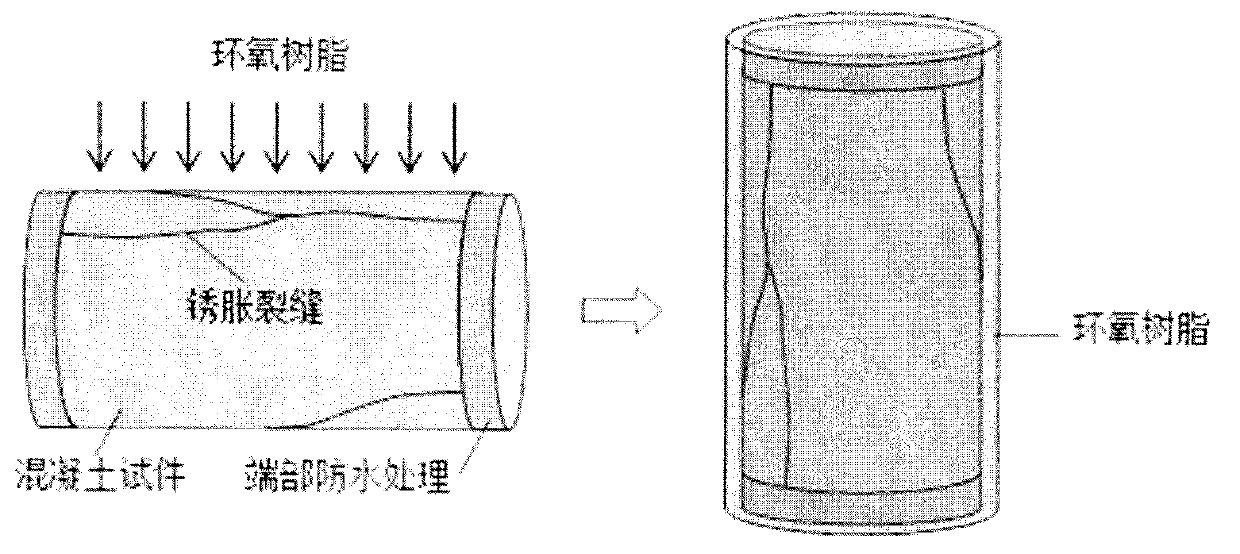

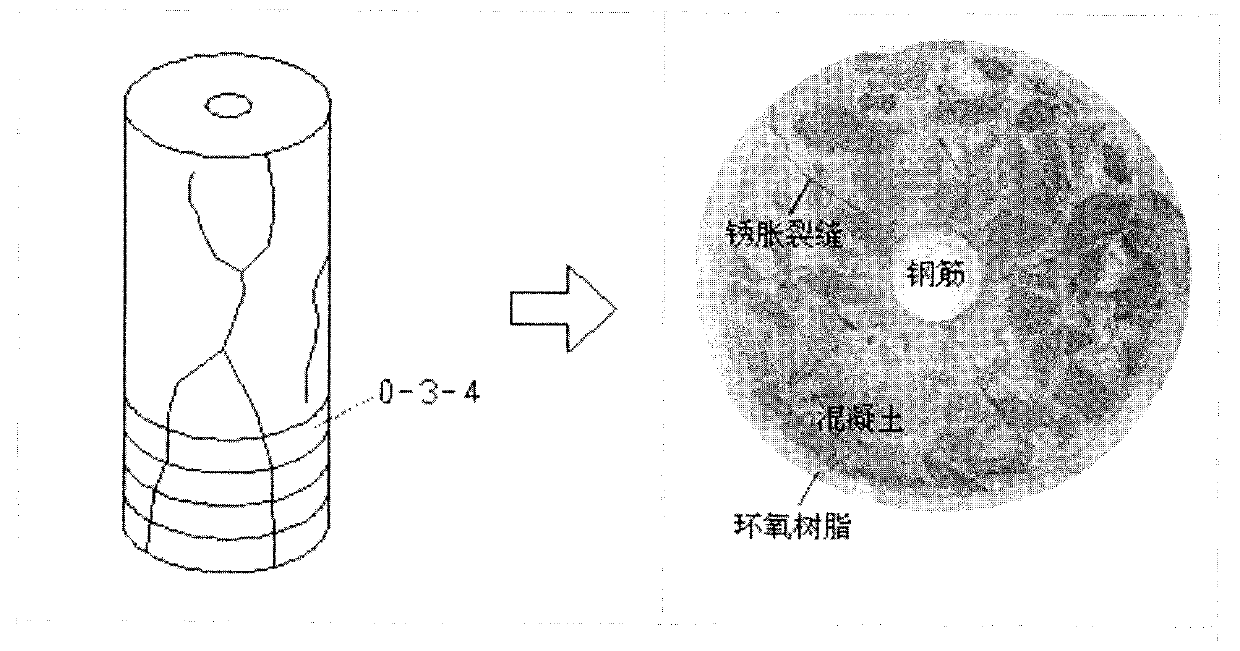

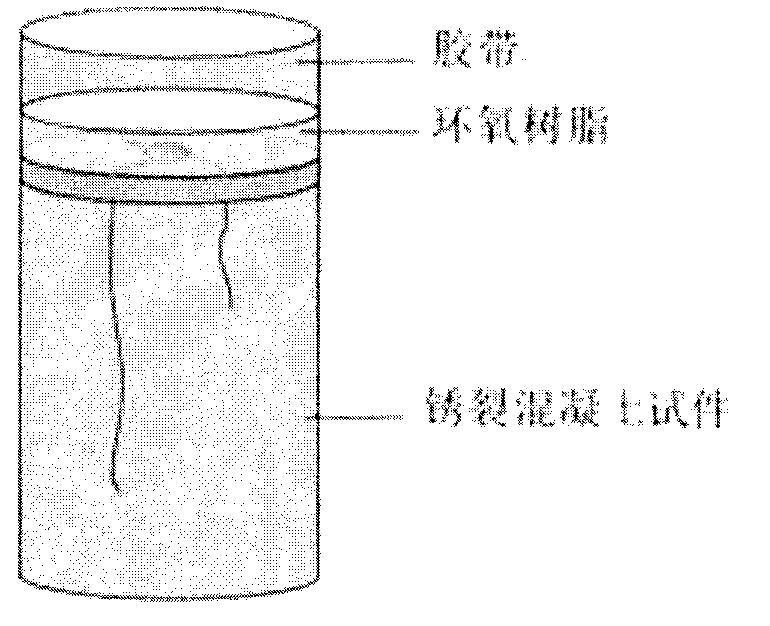

[0027] The method for the observation reinforced concrete rust crack that the present invention is based on two-stage rust crack model concrete implementation below in detail, includes but not limited to the concrete specimen (being called for short the first specimen) of complete rust crack, rust expansion crack penetrating the concrete protective layer , and the sample preparation and observation of the concrete specimen (referred to as the second specimen) with incomplete rust cracks and rust swelling cracks that have not yet penetrated the concrete protective layer.

[0028] Step 1: Configure low-viscosity epoxy resin

[0029] Use the epoxy resin (i.e. glue A) and curing agent (i.e. glue B) produced by Jinhong glue industry, and configure according to the ratio of volume ratio A glue: B glue = 2.5:1; after configuration, stir evenly along the same direction; The fresh epoxy resin after stirring has a certain viscosity and greater fluidity. At this time, after dipping a sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com