A method and system for controlling bending of high-strength steel

A high-strength steel and high-strength steel plate technology, applied in the field of control, can solve problems such as unfavorable development of new products, and achieve the effects of avoiding a large number of repeated tests, saving materials and time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

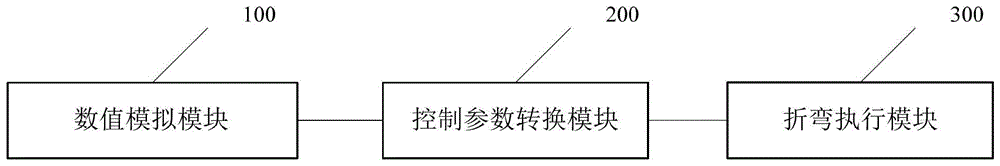

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

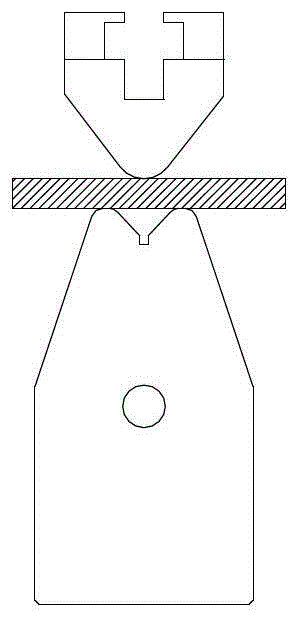

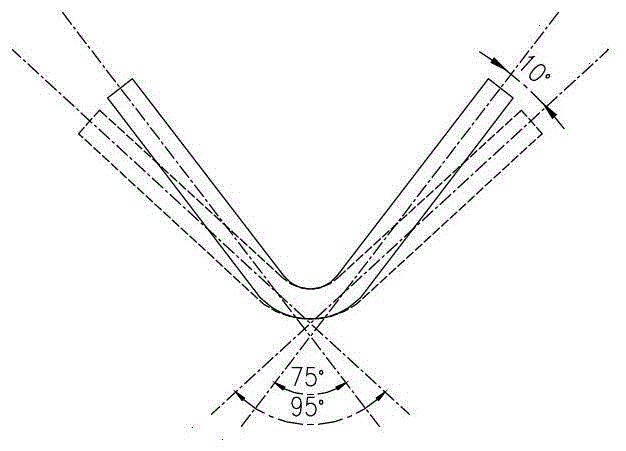

[0019] Due to the springback characteristics of high-strength steel itself, in order to improve efficiency and save test costs, it is necessary to perform some numerical simulation work before bending high-strength steel. Perform some simulations with the bending machine to obtain the required process parameters, such as the initial bending angle and the target bending depth. According to the conversion of these parameters, the pressure that the bending machine needs to be loaded, the deflection compensation and the displacement of the oil cylinder of the bending machine can be obtained. Controlling the bending machine to work according to these parameters can e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com