a stirring device

A technology of stirring device and stirring shaft, which is applied to mixers with rotating stirring devices, dissolving machines, mixers, etc., can solve problems such as reducing the service life of the stirring device, and achieve the effect of improving the service life and preventing collisions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

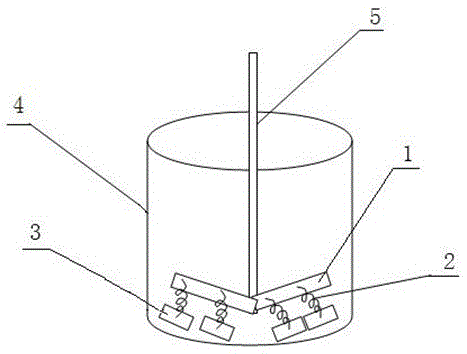

[0024] Such as figure 1 Shown is the structural representation of stirring device of the present invention, and stirring blade 1 is installed on the stirring shaft 5, is connected with 2 auxiliary blades 3 by connecting piece 2 on stirring blade 1, and connecting piece 2 is a spring, by stirring blade 1 and auxiliary Holes are drilled on the blade 3 to fix the connecting piece 2 on the stirring blade 1 and the auxiliary blade 3 . Determine the size of the auxiliary blade 3 according to the size of the stirring blade 1, the length of the auxiliary blade 3 is generally 100mm, made of plastic, or can be made of metal or other polymer materials; the distance between 2 auxiliary blades 3 is 7mm, with Prevent collisions between them; the gap between the auxiliary blade 3 and the bottom of the reactor 4 is 3 mm, so that the auxiliary blade 3 can stir the materials deposited at the bottom of the reactor 4 .

[0025] When in use, first put the material into the reactor 4, then connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com