Method for strengthening sintering clay brick masonry structure through internal prestressed steel anchor rods

A technology of prestressed steel bars and sintered clay, applied in building construction, building maintenance, construction, etc., can solve problems such as wall cracking, achieve the effects of improving seismic bearing capacity, inhibiting wall cracking, and improving seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

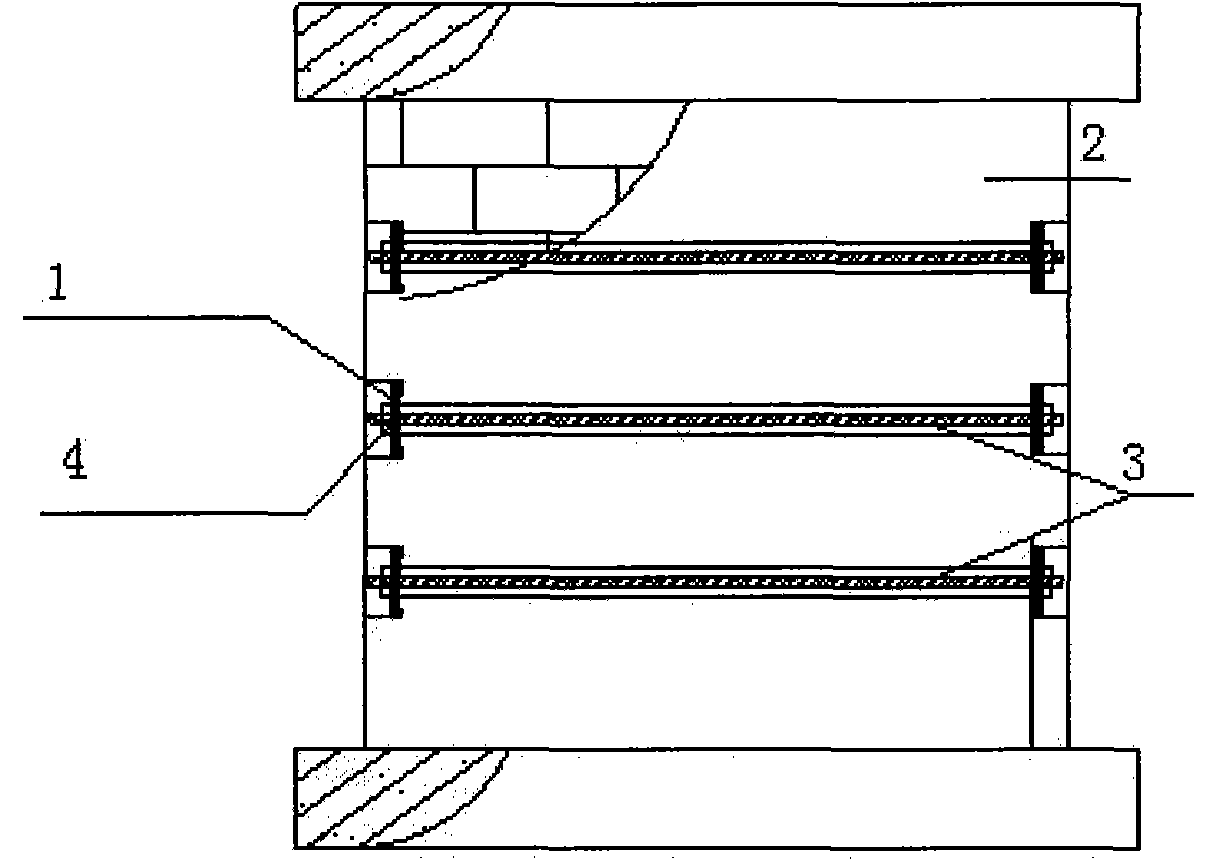

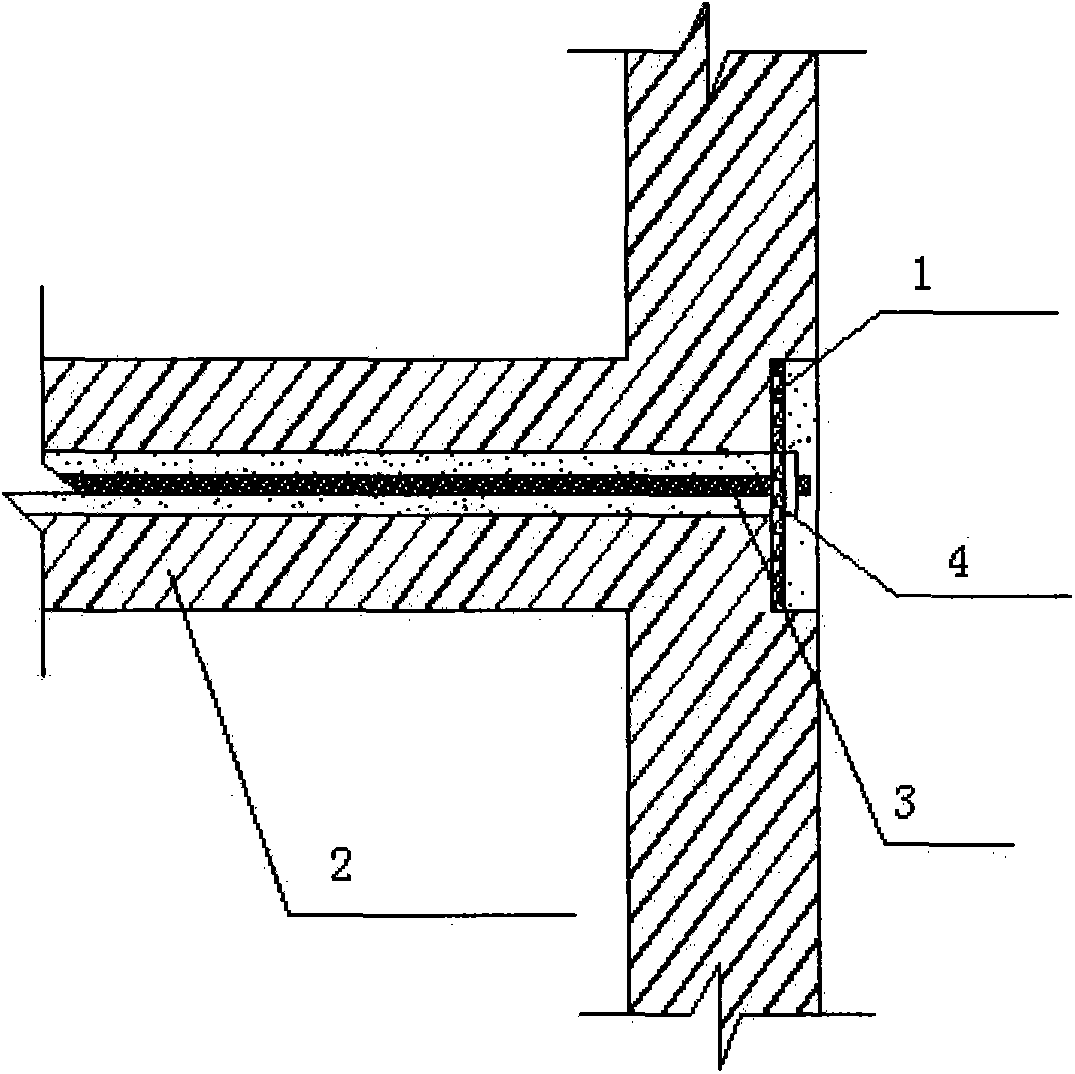

[0023] Such as Figure 1 ~ Figure 2 Shown, the specific embodiment of the present invention is as follows:

[0024] An internal prestressed sintered clay brick masonry structure, including a wall 2 and a prestressed steel anchor bar 3, the wall 2 is composed of sintered clay bricks, and the prestressed steel anchor bar 3 adopts prestressed steel bars of φ16-φ18 and transversely Evenly penetrated in the wall body 2, the longitudinal spacing is 400mm-600mm. The two ends of the prestressed steel anchor rod 3 are prestressed and anchored by the backing plate 1 and the anchor bolt 4, and the anchoring length of both ends is not less than 60mm. A thin-walled steel pipe or plastic pipe is sheathed on the prestressed steel anchor rod 3, and mortar is poured between it and the hole of the fired clay brick. Every 1-2 blocks in the wall body 2 is provided with a vertical reinforcement mesh, and the vertical reinforcement mesh is welded by φ6 steel bars.

[0025] The specific method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com