a handle

A handle seat and handle technology, which is applied in the direction of wing fan handles, wing fan spherical handles, furniture accessories, etc., can solve the problems of high production cost and complex structure of split handles, and achieve the effect of light weight and simple and smooth installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

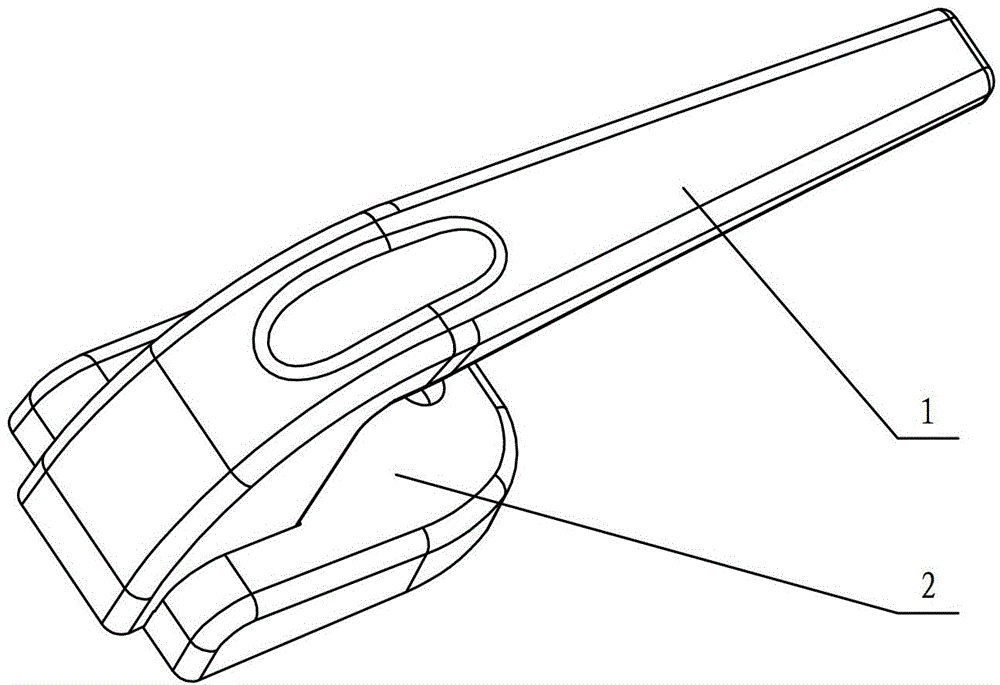

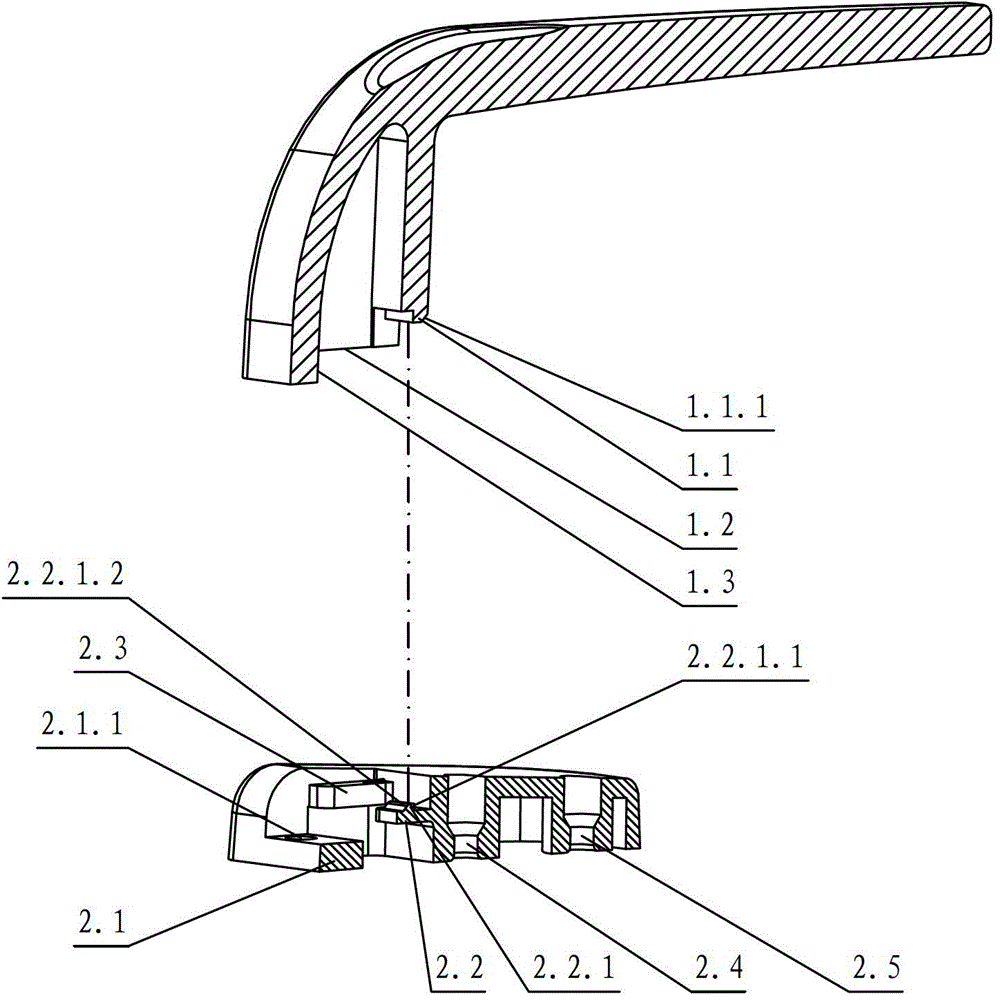

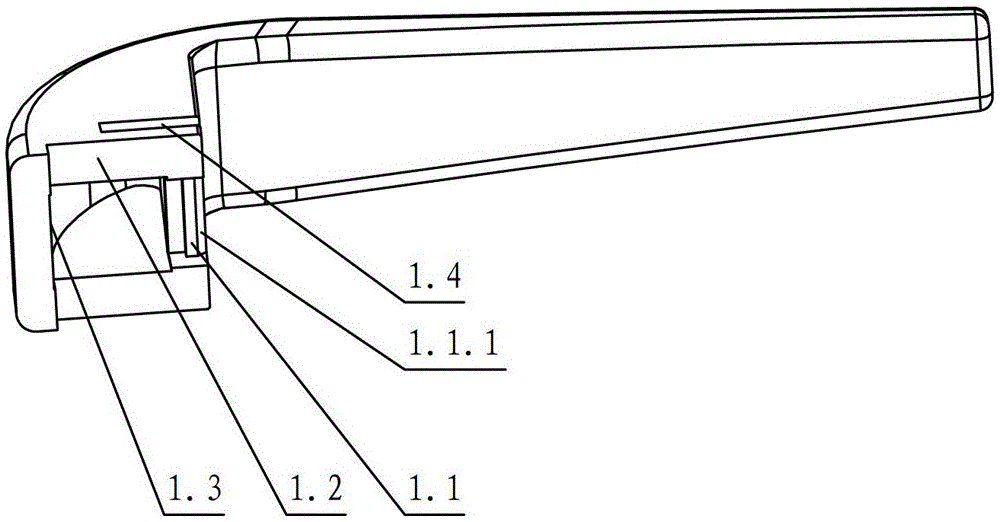

[0026] see Figure 1-Figure 4 , The handle includes a handle 1 and a handle seat 2, the handle seat 2 is provided with an open chute, and the handle 1 slides and is clamped in the open chute.

[0027] A guide protrusion 2.3 is provided on the side wall of the opening chute, a guide groove 1.4 is provided on the outside of the handle 1, and the guide protrusion 2.3 is set in the guide groove 1.4 for sliding. The guide protrusion 2.3 plays a guiding role when the handle is installed, and plays a fastening role after the installation is completed.

[0028] The rear wall of the opening chute is provided with a positioning boss 2.2, and the rear side of the end of the handle 1 is crimped on the positioning boss 2.2.

[0029] The positioning boss 2.2 is provided with a stop boss 2.2.1, and the stop boss 2.2.1 and the rear wall of the opening chute jointly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com