Engine cooling circulation system with bypass cooling function and corresponding vehicle

A technology of engine cooling and circulation system, which is applied in the direction of engine cooling, engine components, machines/engines, etc. It can solve problems such as inability to adjust temperature, low integration, poor engine fuel consumption and emission performance, and reduce engine warm-up start time, cooling cycle system is compact, the effect of reducing fuel consumption and emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

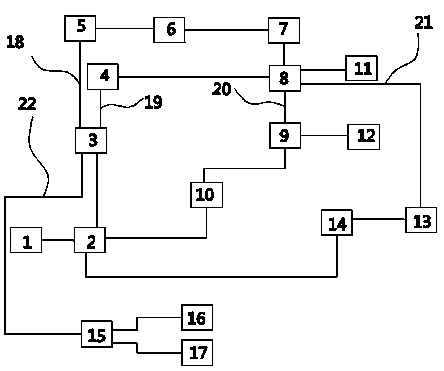

[0029] Embodiment 1 An engine cooling cycle system with split cooling function

[0030] This embodiment provides an engine cooling cycle system with split cooling function, refer to figure 1 ,it includes:

[0031] The coolant tank 1, the coolant tank 1 is used to accommodate the coolant for cooling the engine system, and the coolant tank 1 provides the coolant for the water pump 2, specifically the water pump 2 pumps the coolant from the coolant tank 1 After taking it out, it flows into different parts through pipelines to cool down, including the cylinder block 3, that is, the coolant pumped by the water pump 2 enters the passage of the cylinder block 3.

[0032] The coolant flows out of the cylinder block 3 (after the coolant enters the channel of the cylinder block), and then flows into the water jacket 4 on the exhaust side of the cylinder head through the second diversion pipe 19, and at the same time flows in through the first diversion pipe 18 when the temperature o...

Embodiment 2

[0041] Embodiment 2 A vehicle

[0042] The present embodiment provides a vehicle including a cooling circulation system for cooling an engine.

[0043] The only difference between this vehicle and the prior art is that the cooling circulation system is the engine cooling circulation system provided by Embodiment 1 with a split function.

[0044] The structure of other parts of this vehicle is exactly the same as that of the vehicle in the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com