Universal multi-mode gas distribution mechanism

A gas distribution mechanism and multi-mode technology, applied in mechanical equipment, engine components, engine control, etc., can solve problems such as high fuel consumption, long mileage, and large displacement of a single engine, and achieve reduced fuel consumption and emissions, fast switching, and improved The effect of braking power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

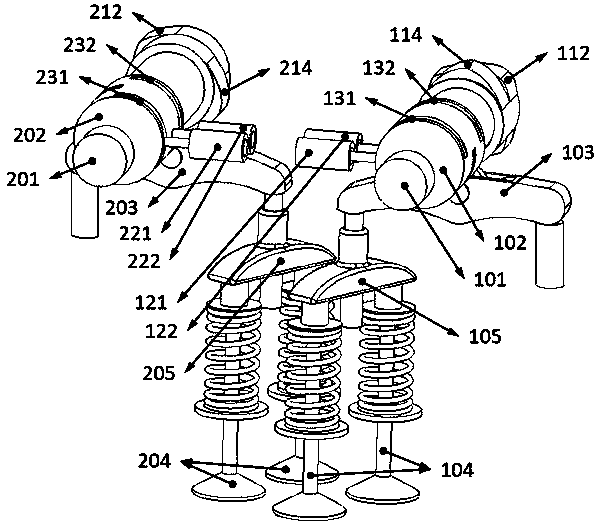

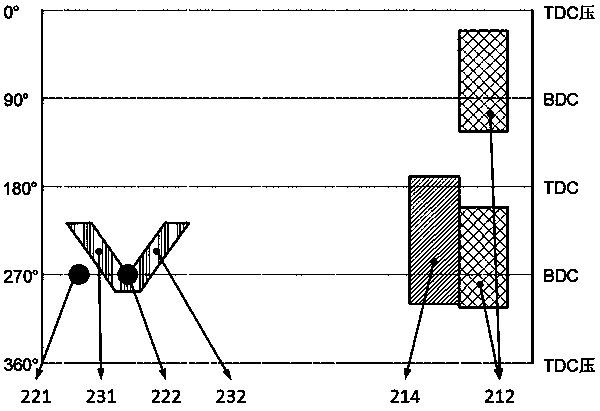

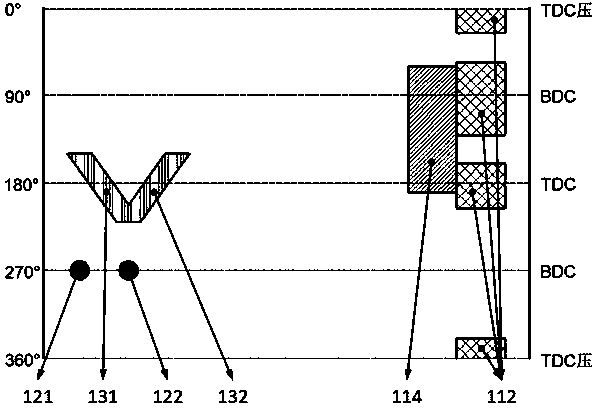

[0040] figure 1 It is a schematic diagram of the first embodiment of the universal multi-mode valve train. figure 2 and image 3 They are the expanded schematic diagrams of the intake bushing and the exhaust bushing respectively.

[0041]The intake valve sleeve 202 is provided with an intake driving cam 214 , an intake braking cam 212 , a first intake switching slot 231 and a second intake switching slot 232 . The exhaust valve sleeve 102 is provided with an exhaust driving cam 114 , an exhaust braking cam 112 , a first exhaust switch slot 131 and a second exhaust switch slot 132 . The switching mechanism includes a first intake switching mechanism 221 , a second intake switching mechanism 222 , a first exhaust switching mechanism 121 and a second exhaust switching mechanism 122 . The intake drive cam 214 has a lobe during the intake stroke, the intake detent cam 212 has a lobe near each bottom dead center, the exhaust drive cam 114 has a lobe during the exhaust stroke, an...

Embodiment 2

[0048] Figure 4 It is a schematic diagram of the second embodiment of the universal multi-mode valve train. Compared with embodiment 1, embodiment 2 uses a branched rocker arm to drive a pair of valve assemblies.

Embodiment 3

[0050] Figure 5 It is a schematic diagram of the second embodiment of the universal multi-mode valve train. Figure 6 and Figure 7 They are the expanded schematic diagrams of the intake bushing and the exhaust bushing respectively. The intake valve sleeve 202 is provided with an intake driving cam 214 , an intake zero-lift cam 210 , an intake braking cam 212 , a first intake switching slot 231 and a second intake switching slot 232 . The exhaust valve sleeve 102 is provided with an exhaust driving cam 114 , an exhaust zero-lift cam 110 , an exhaust braking cam 112 , a first exhaust switch slot 131 and a second exhaust switch slot 132 . The phase of the intake camshaft 201 is adjusted by the camshaft phase adjustment mechanism 3 . The switching mechanism includes an intake first switching mechanism 221 , an intake second switching mechanism 222 , an intake third switching mechanism 223 , an exhaust first switching mechanism 121 , an exhaust second switching mechanism 122 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com