Fan hub lightning guiding wire connecting method and lightning guiding system

A technology of wire connection and connection method, which is applied in the field of fixed connection method and system device of wind turbine hub lightning conductor, can solve the problem that there is no improvement suggestion for wind turbine hub lightning protection system, and can not really solve the problem of wind turbine hub lightning protection , did not find the hub of the wind turbine and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

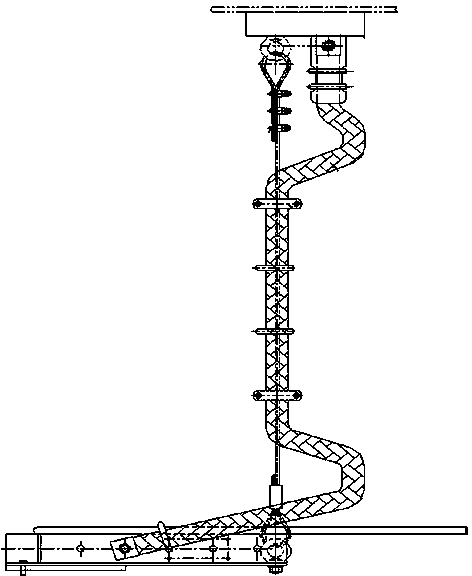

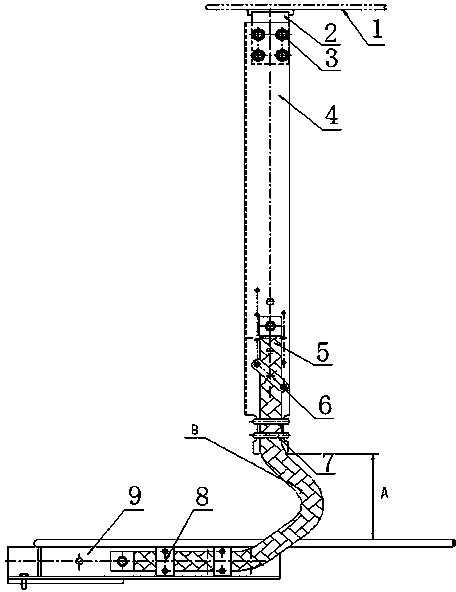

[0045] A wind turbine hub lightning guiding wire system, comprising a blade root lightning receiving base 2, a blade end mounting plate 4, fixing bolts 3, a hub bracket 9, a lightning guiding wire 5 and a clamp 6; wherein, the blade root lightning receiving The base 2 is fixed on the manhole cover plate 1 at the blade end by fixing bolts; the cross section of the blade end mounting plate 4 is "L" shape, which is convenient to improve the strength of the blade end mounting plate, and also facilitates the positioning of the lightning conductor 5 when it is installed. Rely on; the blade end mounting plate 4 is fixed on the blade root lightning receiving base 2 through the fastener 3, after the blade end mounting plate 4 is installed on the blade root lightning receiving base 2, then the blade root lightning receiving base 2 is connected to the blade Manhole cover plate 1 at the end, and ensure that there should be a gap of 1-500mm between the lower end surface of the blade end mou...

Embodiment 2

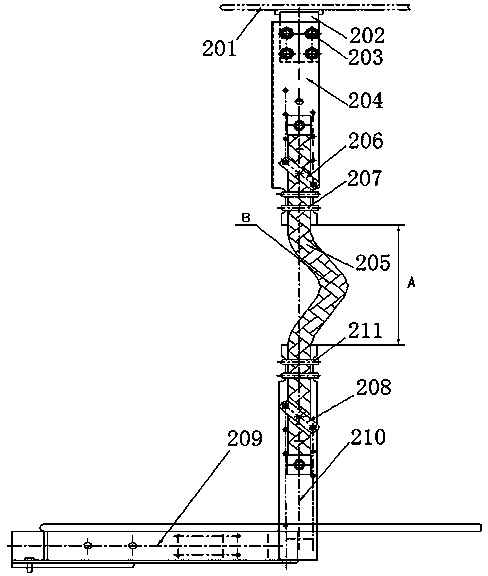

[0054] The principle of the second embodiment is the same as that of the first embodiment, so the following only briefly introduces this embodiment. A wind turbine hub lightning conductor system, comprising a blade root lightning terminal base 202, a blade end mounting plate 204, fixing bolts 203, a hub bracket 209, a lightning conductor 205 and a clamp 206; wherein, the blade root lightning terminal The base 202 is fixed on the blade end manhole cover plate 201 through fixing bolts; one end of the lightning guiding wire 205 is fixed on the blade end mounting plate 204 through a clamp 206, and the other end of the lightning guiding wire 205 is fixed on the hub through a hub wire clamp 208 On the bracket 209, there is a closing opening at the lower end of the blade end mounting plate 204 to form a groove. When the lightning conductor 205 passes through the closing, it is further bound to the lower end surface part of the blade end mounting plate 204 through a cable tie 207 to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com